F Handling Relays

F-1 Vibration and Shock

Relays are precision components. Regardless of whether or not they

are mounted, do not exceed the rated values for vibration and shock.

The vibration and shock values are determined individually for each

Relay, so check the individual Relay specifications in this catalog.

If a Relay is subjected to abnormal vibration or shock, its original

performance capabilities will be lost.

F-2 Dropped Products

Do not use a product that has been dropped, or that has been taken

apart. Not only may its characteristics not be satisfied, but it may be

susceptible to damage or burning.

G Relays for Printed Circuit Boards

(PCBs)

G-1 Selecting PCBs

(1) PCB Materials

PCBs are classified into those made of epoxy and those made of

phenol. The following table lists the characteristics of these PCBs.

Select one, taking into account the application and cost. Epoxy PCBs

are recommended for mounting Relays to prevent the solder from

cracking.

G-2 Selecting PCBs

(2) PCB Thickness

The PCB may warp due to the size, mounting method, or ambient

operating temperature of the PCB or the weight of components

mounted to the PCB. Should warping occur, the internal mechanism

of the Relay on the PCB will be deformed and the Relay may not

provide its full capability. Determine the thickness of the PCB by

taking the material of the PCB into consideration.

In general, PCB thickness should be 0.8, 1.2, 1.6, or 2.0 mm. Taking

Relay terminal length into consideration, the optimum thickness is

1.6 mm.

G-3 Selecting PCBs

(3) Terminal Hole and Land Diameters

Refer to the following table to select the terminal hole and land

diameters based on the Relay mounting dimensions. The land

diameter may be smaller if the land is processed with through-hole

plating.

G-4 Mounting Space

A Ambient Temperature

When mounting a Relay, check this catalog for the specified amount

of mounting space for that Relay, and be sure to allow at least that

much space.

When two or more Relays are mounted, their interaction may

generate excessive heat. In addition, if multiple PCBs with Relays

are mounted to a rack, the temperature may rise excessively. When

mounting Relays, leave enough space so that heat will not build up,

and so that the Relays' ambient temperature remains within the

specified operating temperature range.

B Mutual Magnetic Interference

When two or more Relays are mounted, Relay characteristics may

be changed by interference from the magnetic fields generated by

the individual Relays. Be sure to conduct tests using the actual

devices.

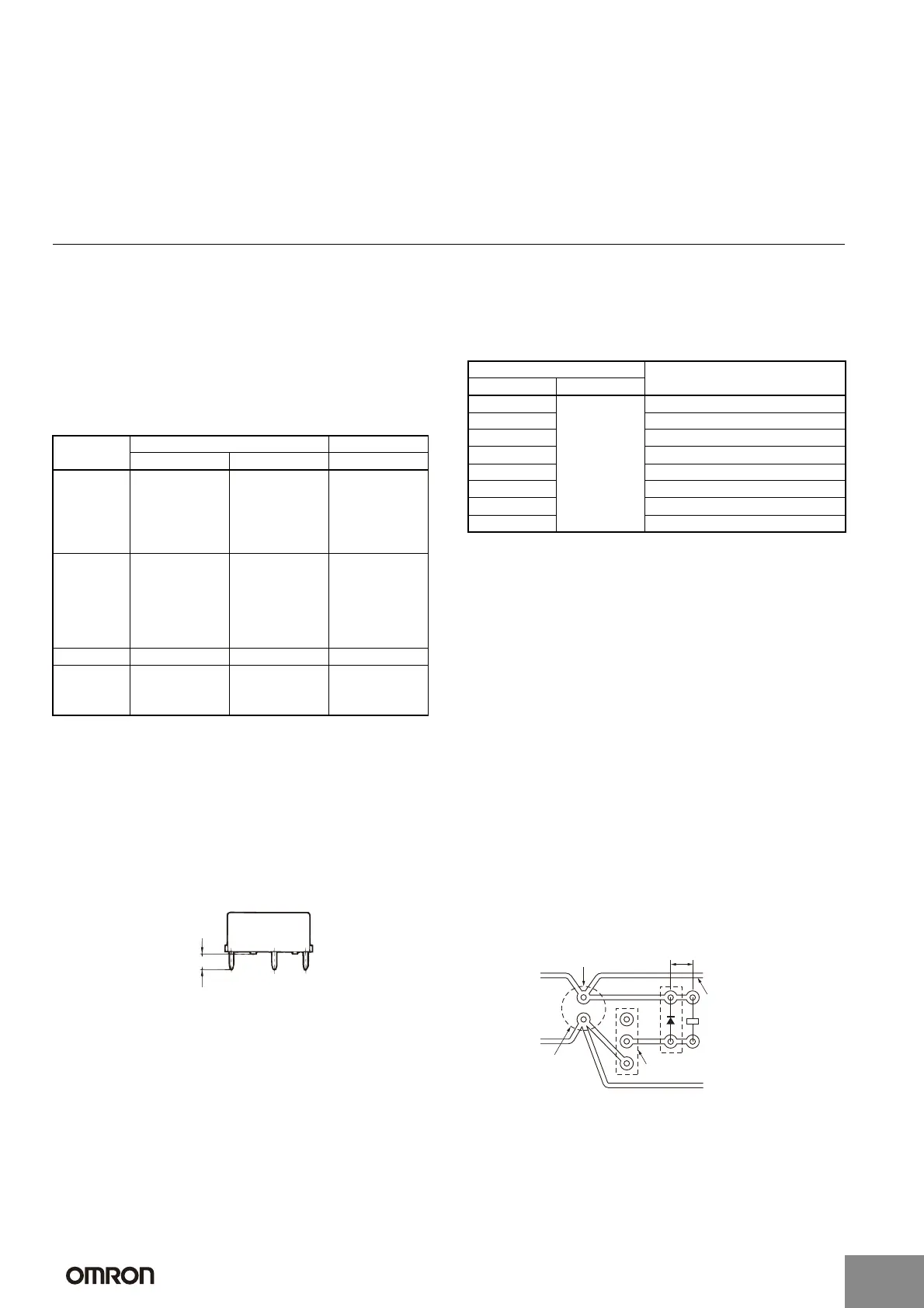

G-5 Pattern Design for Noise Countermeasures

A Noise from Coils

When the coil is turned OFF, reverse power is generated to both

ends of the coil and a noise spike occurs. As a countermeasure,

connect a surge absorbing diode. The diagram below shows an

example of a circuit for reducing noise propagation.

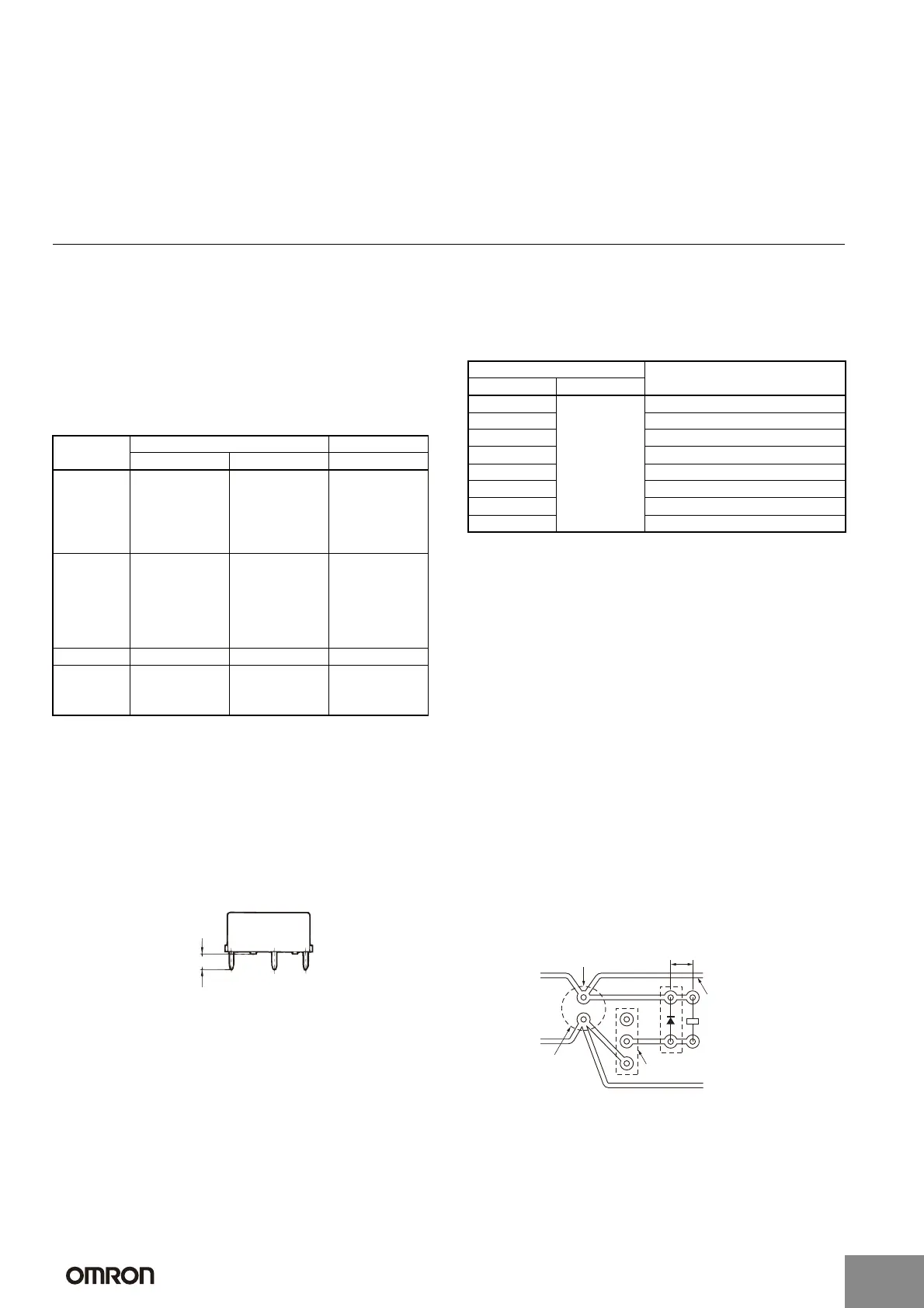

Material Epoxy Phenol

Item Glass epoxy (GE) Paper epoxy (PE) Paper phenol (PP)

Electrical

characteristics

• High insulation

resistance.

• Insulation

resistance hardly

affected by

moisture

absorption.

Characteristics

between glass

epoxy and phenol

New PCBs are

highly insulation-

resistive but easily

affected by

moisture

absorption.

Mechanical

characteristics

• The dimensions

are not easily

affected by

temperature or

humidity.

• Suitable for

through-hole or

multi-layer PCBs.

Characteristics

between glass

epoxy and phenol

• The dimensions

are easily

affected by

temperature or

humidity.

• Not suitable for

through-hole

PCBs.

Relative cost High Moderate Low

Applications Applications that

require high

reliability.

Characteristics

between glass

epoxy and phenol

Applications in

comparatively good

environments with

low-density wiring.

Terminal length

Terminal hole diameter (mm) Minimum land diameter (mm)

Nominal value Tolerance

0.6 ±0.1 1.5

0.8 1.8

1.0 2.0

1.2 2.5

1.3 2.5

1.5 3.0

1.6 3.0

2.0 3.0

Smoothing

capacitor

Relay drive transistor

Power supply lin

Noise is superimposed

on the power supply line,

so a separate pattern is

connected from a

smoothing capacitor to

supply coil power.

The pattern will

form an antenna

circuit, so make

it as short as

possible.

http://www.ia.omron.com/

C-11

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...