11-14

11-4 Manual Tuning

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

11

Adjustment Functions

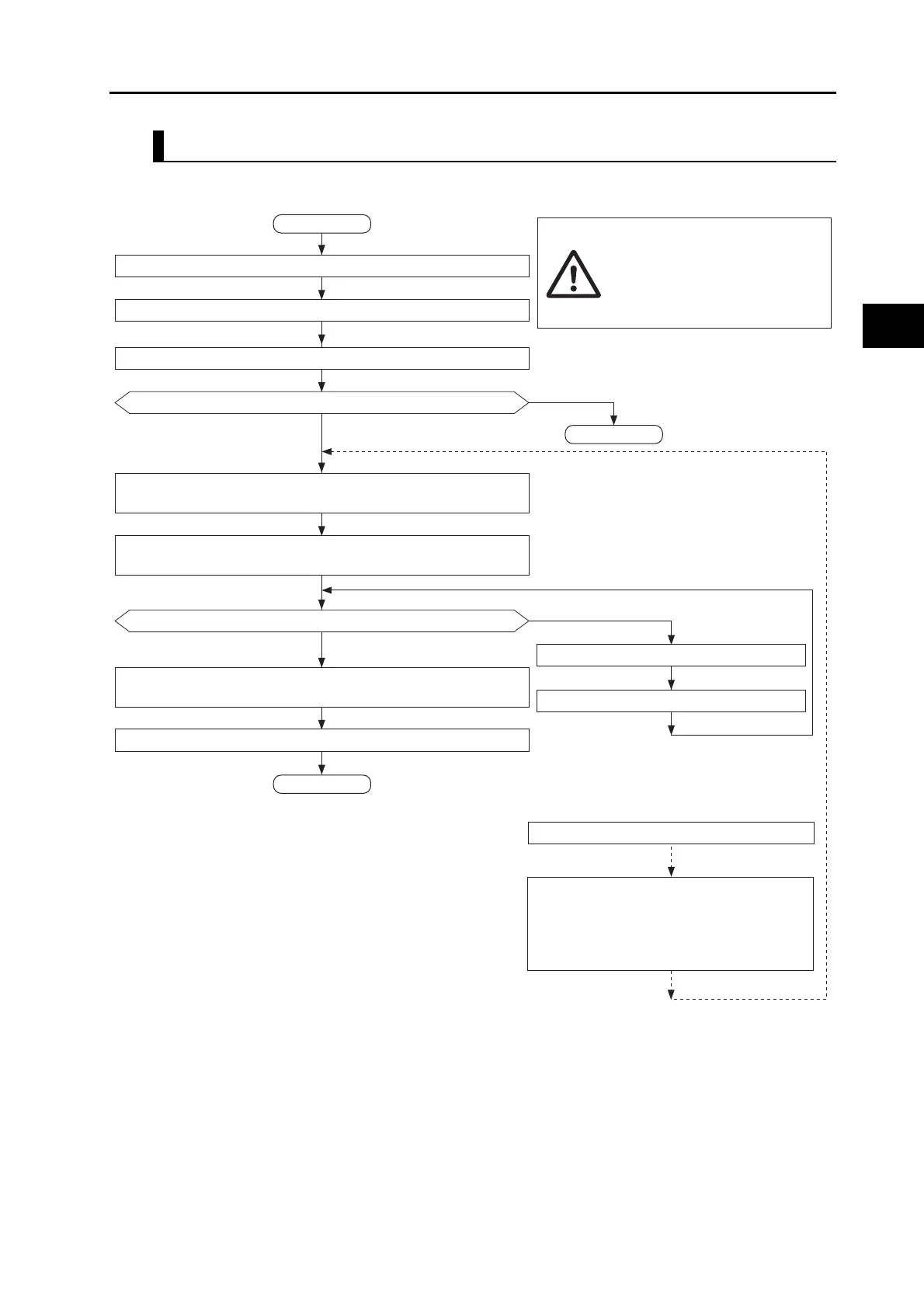

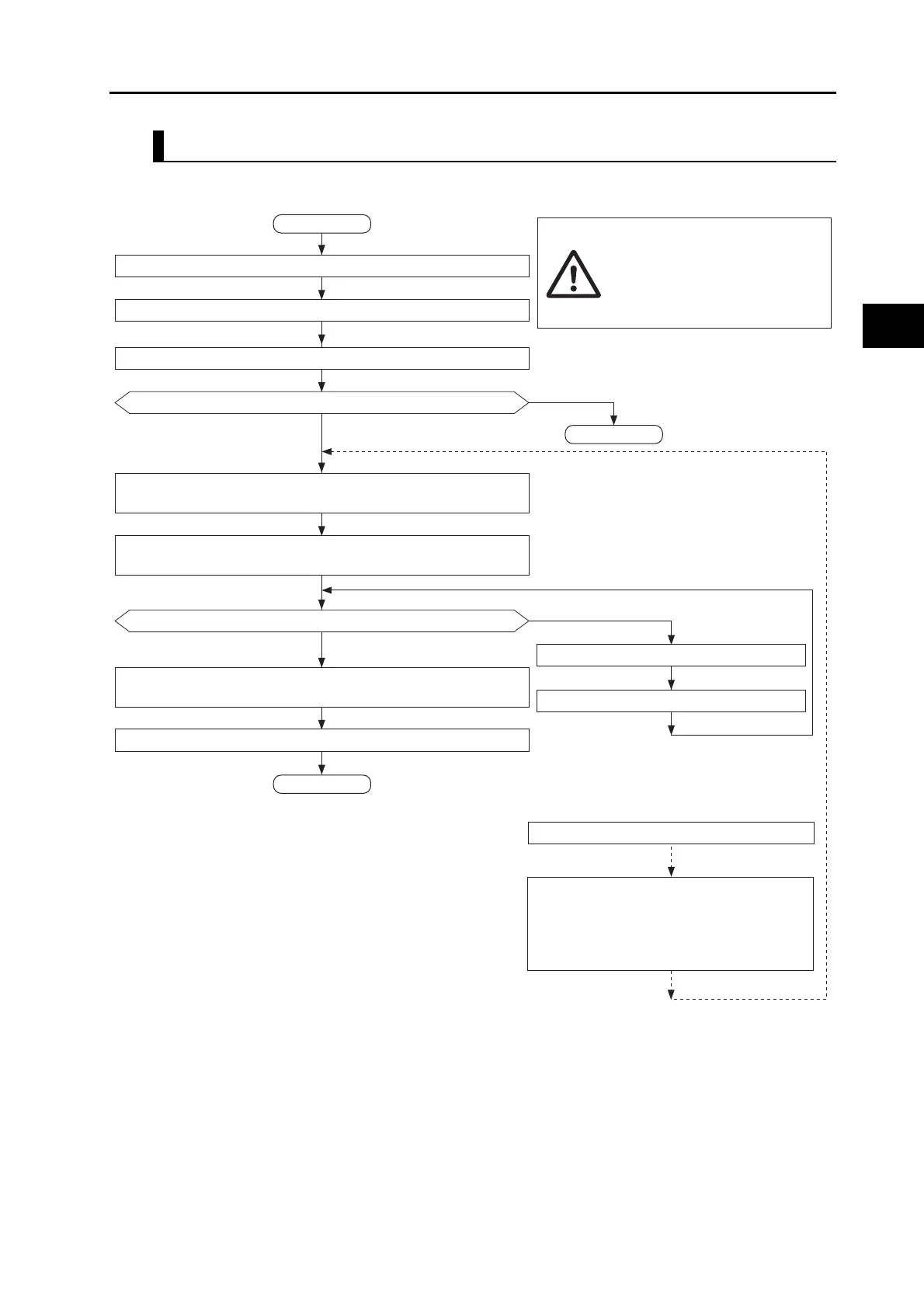

Position Control/Fully-closed Control Mode Adjustment

Use the following procedure to perform the adjustment in position control for the Servo Drive.

Write to the EEPROM in the Parameter Write mode.

Start adjustment.

Yes

No

Adjustment completed.

Disable realtime autotuning (3002 hex = 0)

Set each parameter according to the parameter settings for different applications.

Operate based on the normal operation pattern and load.

Are the positioning time and other performances satisfied?

Adjustment completed.

Increase Speed Loop Gain 1 (3101 hex) to the extent

that hunting does not occur upon servo lock.

Decrease Speed Loop Integral Time Constant 1 (3102 hex)

to the extent that hunting does not occur upon servo lock.

Does hunting or vibration occur when the motor rotates?

No

Decrease Speed Loop Gain 1 (3101 hex).

Increase Speed Loop Integral Time Constant 1 (3102 hex).

Increase position loop gain to the extent

that overshooting does not occur.

Yes

If vibration persists after repeated adjustments

or the positioning is slow:

Increase Torque Command Filter Time Constant 1 (3104 hex).

Never adjust or set parameters to extreme values,

as it will make the operation unstable.

Failure to follow this guideline may result in injury.

Gradually change the value to adjust the

gain while checking the motor operation.

Set the damping frequencies in the

Notch 1 Frequency Setting (3201 hex),

Notch 2 Frequency Setting (3204 hex),

Notch 3 Frequency Setting (3207 hex), and

Notch 4 Frequency Setting (3210 hex).

Loading...

Loading...