12-29

12-4 Troubleshooting

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

12

Troubleshooting and Maintenance

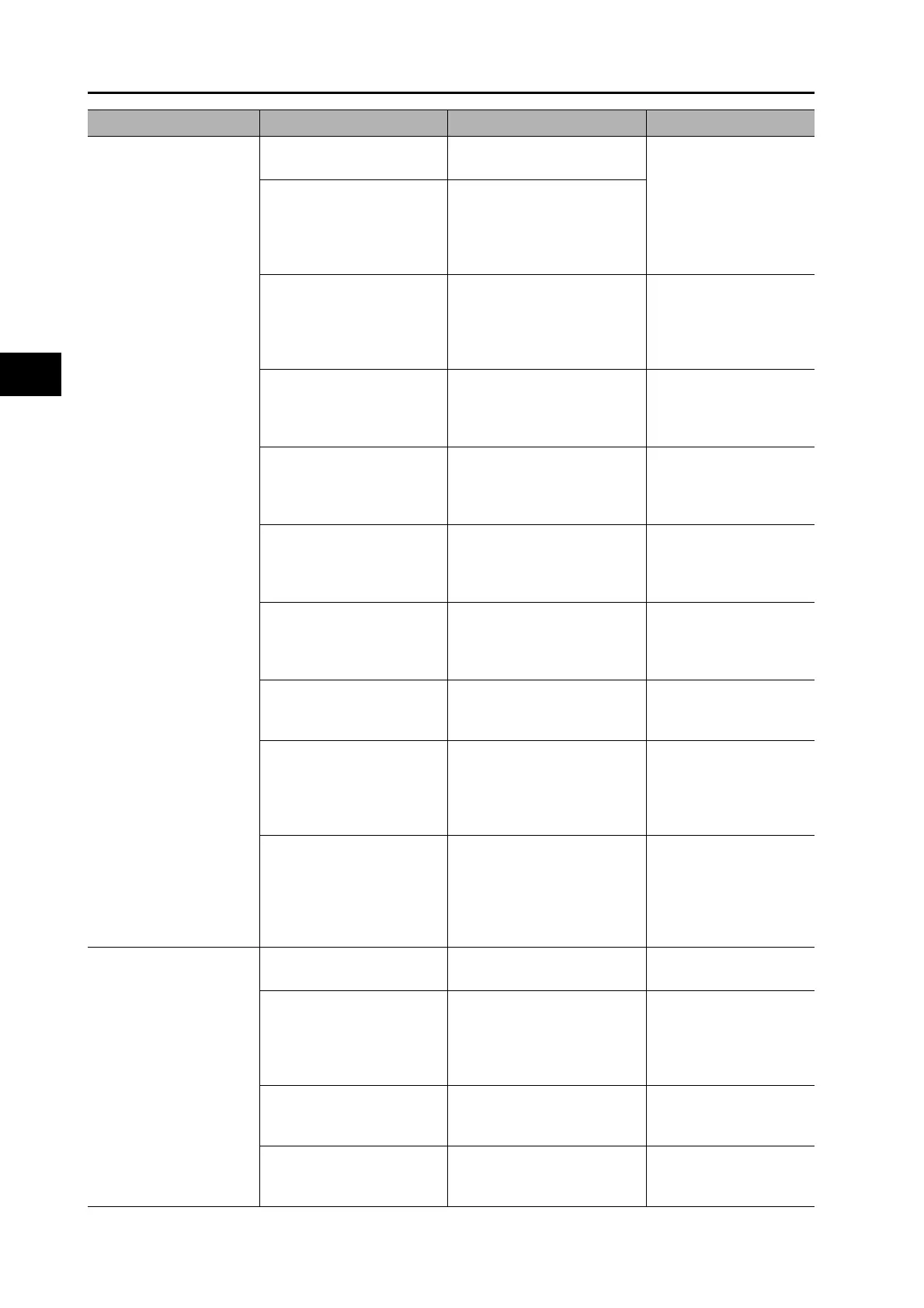

The Servomotor or the

load generates abnormal

noise or vibration.

The Position Loop Gain 1

(3100 hex) is too large.

Review the setting of object

3100 hex.

Use the CX-Drive or the

analog monitor to

measure the response

and adjust the gain.

The Speed Loop Gain 1

(3101 hex) and the Speed

Loop Integral Time Constant

1 (3102 hex) are balanced

incorrectly.

Review the set values of

objects 3101 hex and 3102

hex.

Noise is entering into the

control I/O signal cable

because the cable does not

meet specifications.

Check to see if the cable is a

twisted-pair cable or shielded

twisted-pair cable with core

wires that are at least 0.08 mm

dia.

Use a control I/O signal

cable that meets

specifications.

Noise is entering into the

control I/O signal cable

because the cable is longer

than the specified length.

Check the length of the control

I/O signal cable.

Shorten the control I/O

signal cable to 3 m or

less.

Noise is entering into the

cable because the encoder

cable does not meet

specifications.

Check to see if it is a shielded

twisted-pair cable with core

wires that are at least 0.12 mm

dia.

Use an encoder cable

that meets specifications.

Noise is entering into the

encoder cable because the

cable is longer than the

specified length.

Check the length of the

encoder cable.

Shorten the encoder

cable to less than 50 m.

Noise is entering into the

signal lines because the

encoder cable is stuck or the

sheath is damaged.

Check the encoder cable for

damage.

Correct the encoder

cable's pathway.

Excessive noise on encoder

cable.

Check to see if the encoder

cable is bound together with or

too close to high-current lines.

Install the encoder cable

where it won't be

subjected to surges.

The FG's potential is

fluctuating due to devices

near the Servomotor, such

as welding machines.

Check for ground problems

(loss of ground or incomplete

ground) at equipment such as

welding machines near the

Servomotor.

Ground the equipment

properly and prevent

current from flowing to

the encoder FG.

Errors are being caused by

excessive vibration or shock

on the encoder.

There are problems with

mechanical vibration or

Servomotor installation (such

as the precision of the

mounting surface, attachment,

or axial offset).

Reduce the mechanical

vibration or correct the

Servomotor's installation.

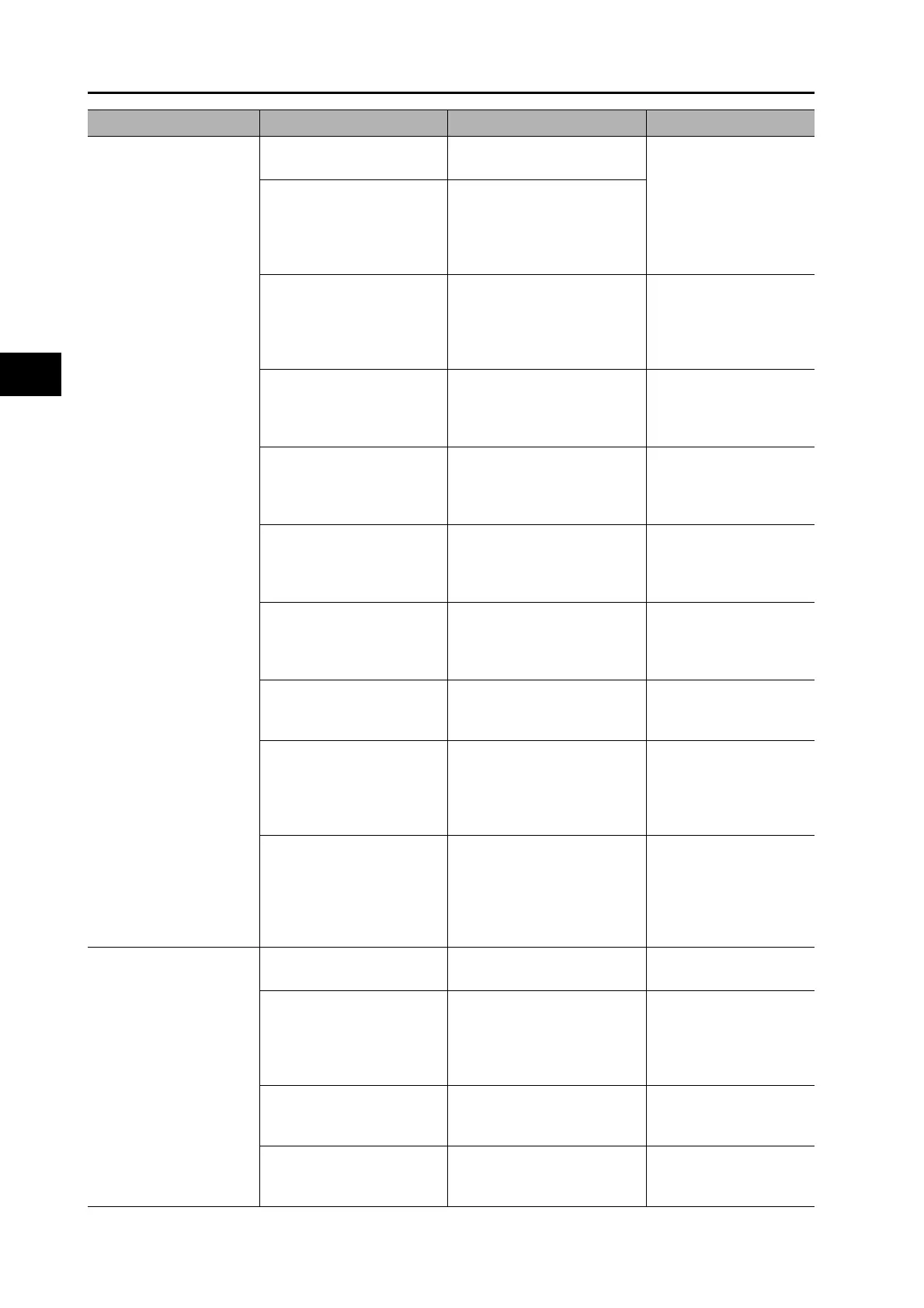

Overshooting at startup or

when stopping

The Position Loop Gain 1

(3100 hex) is too large.

Review the setting of object

3100 hex.

Adjust the gain to prevent

overshooting.

The Speed Loop Gain 1

(3101 hex) and the Speed

Loop Integral Time Constant

1 (3102 hex) are balanced

incorrectly.

Review the set values of

objects 3101 hex and 3102

hex.

Use the CX-Drive or the

analog monitor to

measure the response

and adjust the gain.

The machine rigidity set by

realtime autotuning is

incorrect.

Review the setting of the

machine rigidity.

Match the machine

rigidity setting to the load

rigidity.

The set inertia ratio differs

from the load.

Review the set value of the

Inertial Ratio (3004 hex).

Adjust the set value of

object 3004 hex with the

load.

Symptom Probable cause Items to check Measures

Loading...

Loading...