3-1

3. Periodic Maintenance

Periodic maintenance is essential for top perfor-

mance and long genset life. Use Table 3-1 as a

guide for normal periodic maintenance. In hot and

dusty environments some maintenance procedures

should be performed more frequently, as indicated

by the footnotes in the table. Keeping a log of main-

tenance performed and hours run will help you keep

genset maintenance regular and provide a basis for

supporting warranty claims.

Maintenance, replacement or repair of emission

control devices and systems may be performed by

any engine repair establishment or individual. How-

ever, warranty work must be completed by an au-

thorized Onan dealer.

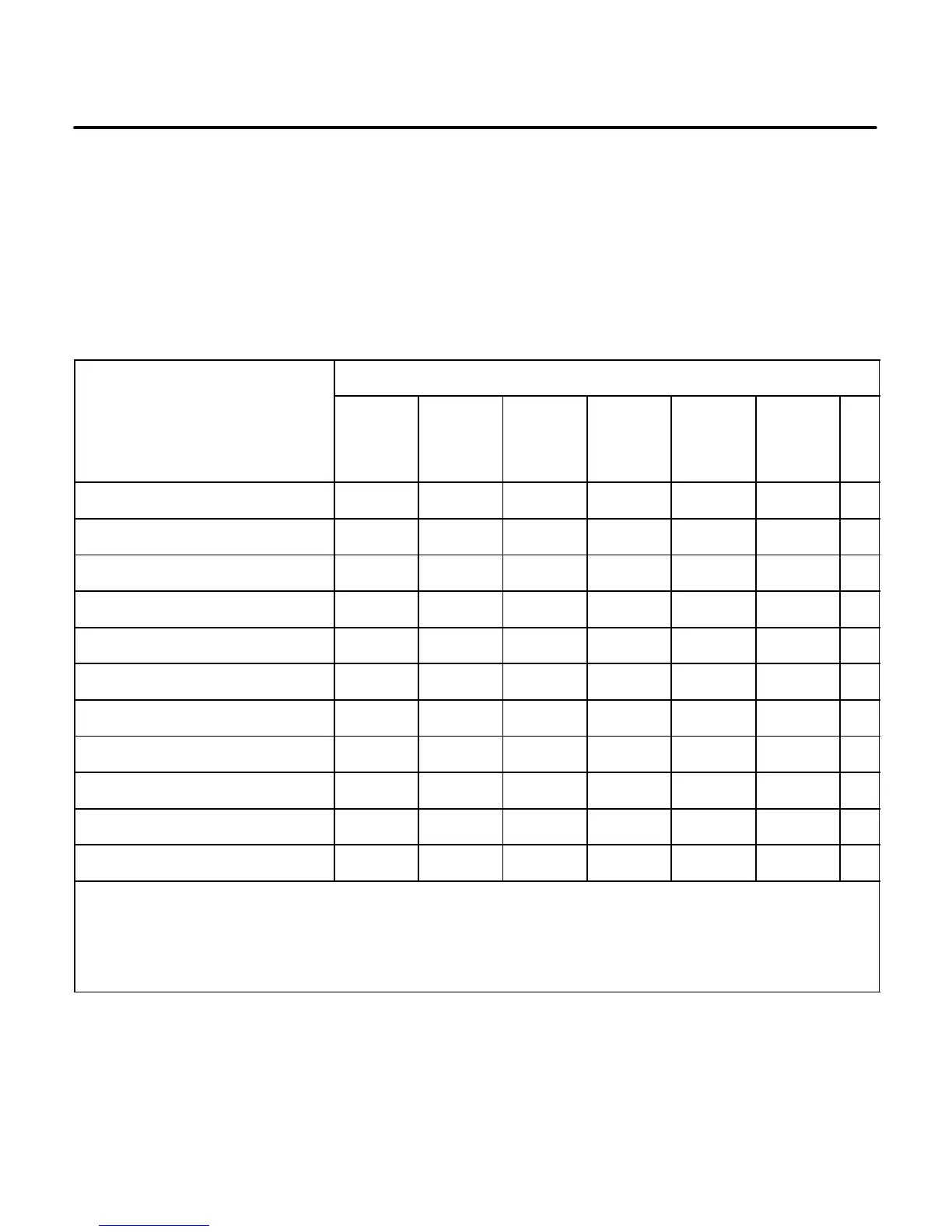

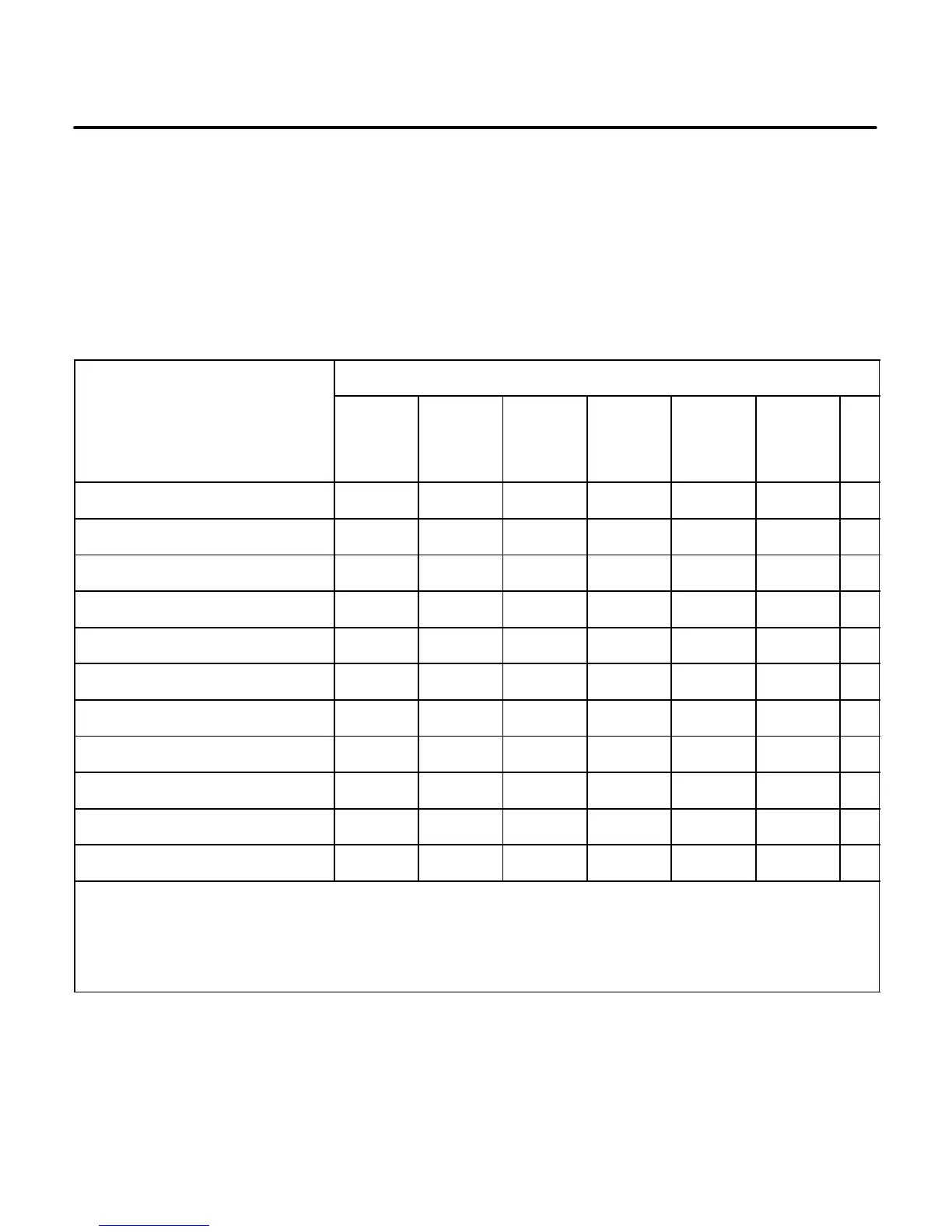

TABLE 3-1. PERIODIC MAINTENANCE SCHEDULE

MAINTENANCE FREQUENCY

MAINTENANCE

PROCEDURE

Every Day

or Every 8

Hours

After First

20 Hours

Every

Month

Every 50

Hours

Every 150

Hours

Every 450

Hours

P

a

g

e

General Inspections X 3-2

Check Engine Oil Level X 3-3

Clean and Check Battery X

3

3-5

Clean Spark Arrestor X 3-7

Change Engine Oil & Oil Filter X

1

X

2,

3,

4

3-4

Replace Air Filter Element X

2

3-5

Replace Spark Plugs X

5

3-6

Clean Engine Cooling Fins X

2

–

Replace Fuel Filter X

5,

6

–

Adjust Valve Lash X

6

–

Clean or Replace Cylinder Heads X

6

–

1 – As a part of engine break-in, change the engine oil after the first 20 hours of operation.

2 – Perform more often when operating in dusty environments.

3 – Perform more often when operating in hot weather.

4 – Perform at least once a year.

5 – Perform sooner if engine performance deteriorates.

6 – Must be performed by a trained and experienced mechanic (authorized Onan dealer).

Loading...

Loading...