4-1

4. Preparing for Service

TROUBLESHOOTING

Refer to Section 11. Troubleshooting before starting

work on the genset. Note that some problems have

several possible causes.

SAFETY

There are hazards in servicing gensets. Study Safe-

ty Precautions and become familiar with the haz-

ards listed in Table 4-1. Note the following safe-

guards and ways of avoiding hazards:

• Use personal protection: Wear appropriate

protective safety equipment, such as safety

shoes and safety glasses.

• Do not wear rings or jewelry and do not wear

loose or damp clothing that might get caught in

equipment or conduct electricity.

• Reduce the hazard: A safe, orderly workshop

area and well-maintained equipment reduce

the hazard potential. Keep guards and shields

in place on machinery and maintain equipment

in good working condition. Store flammable liq-

uids in approved containers; away from fire,

flame, spark, pilot light, switches, arc-produc-

ing equipment and other ignition sources. Keep

the workshop clean and well-lighted and pro-

vide adequate ventilation.

• Develop safe work habits: Unsafe actions

cause accidents with tools and machines. Be

familiar with the equipment and know how to

use it safely. Use the correct tool for the job and

check its condition before starting. Comply with

the warnings in this manual and take special

precautions when working around electrical

equipment. Do not work alone if possible and

take no risks.

• Be prepared for an accident: Keep fire extin-

guishers and safety equipment nearby. Agen-

cies such as the Red Cross and public safety

departments offer courses in first aid, CPR and

fire control. Take advantage of this information

to be ready to respond to an accident. Learn to

be safety-conscious and make safety proce-

dures part of the work routine.

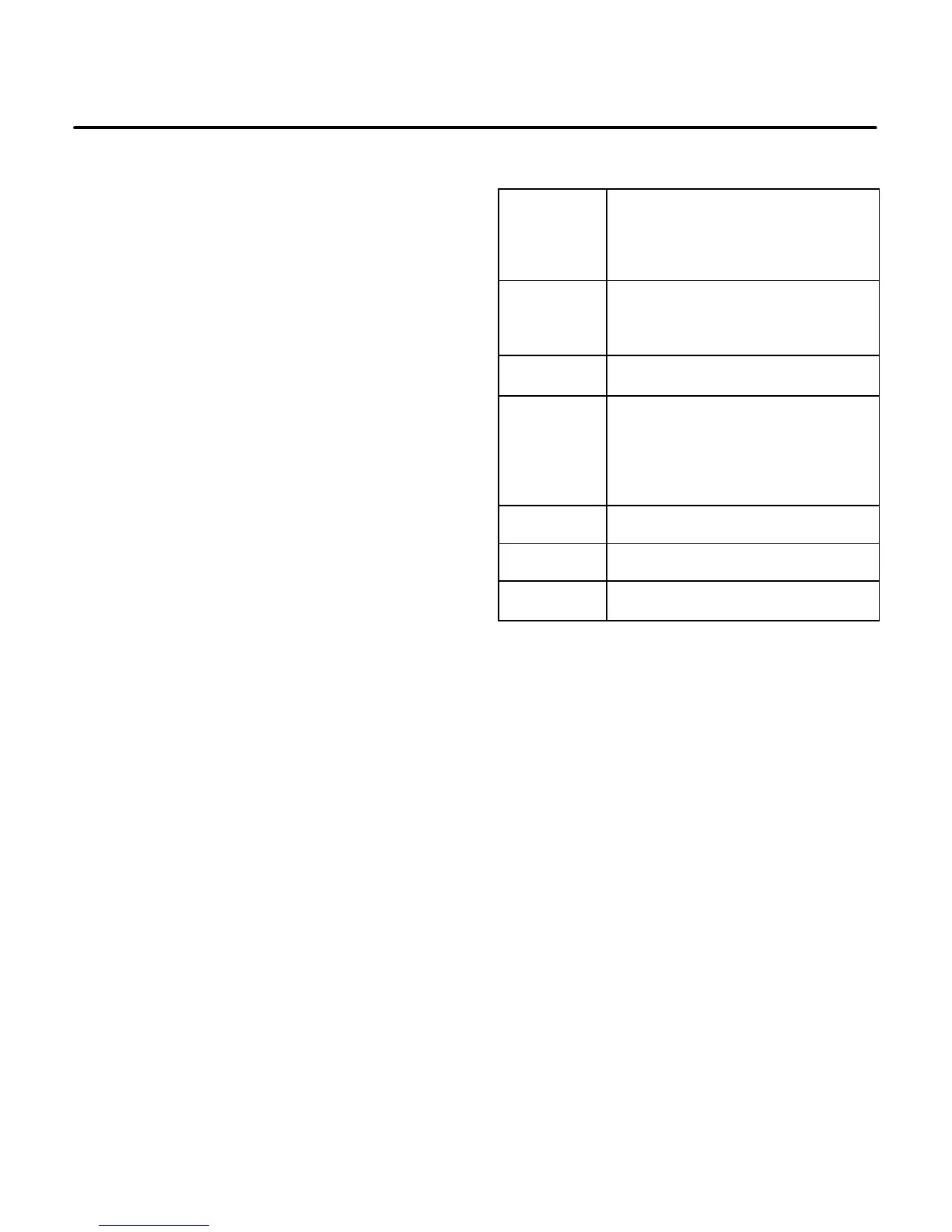

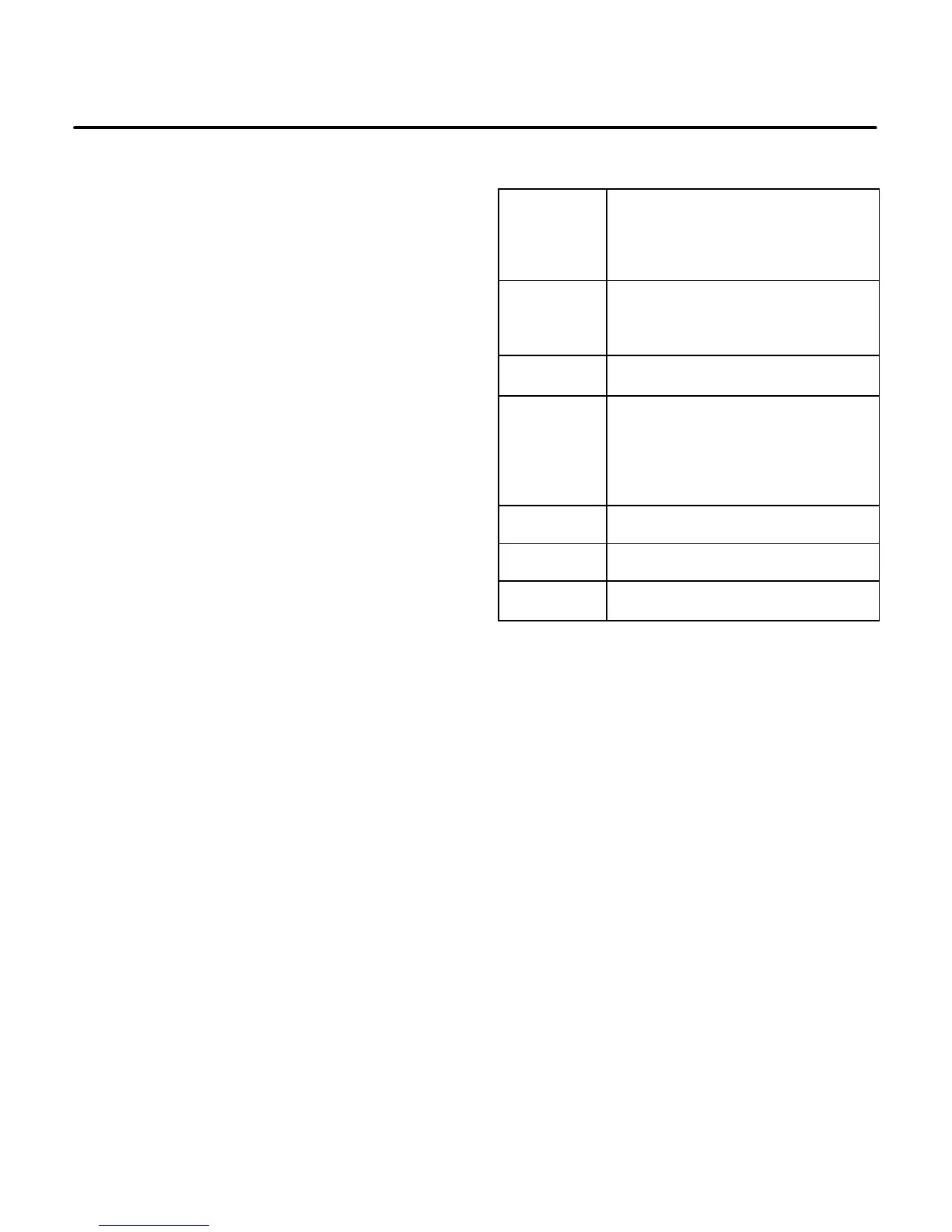

TABLE 4-1. HAZARDS AND THEIR SOURCES

Fire and

Explosion

• Leaking or spilled fuel

• Hydrogen gas from battery

• Oily rags improperly stored

• Flammable liquids improperly

stored

Burns

• Hot exhaust pipes

• Hot engine and generator sur-

faces

• Electrical shorts

Poisonous

Gas

• Operating genset where ex-

haust gases can accumulate

Electrical

Shock (AC)

• Improper generator connec-

tions

• Faulty wiring

• Working in damp conditions

• Jewelry touching electrical

components

Rotating

Machinery

• Fan guards not in place

Slippery

Surfaces

• Leaking or spilled oil

Heavy

Objects

• Removing genset from vehicle

• Removing heavy components

SPECIAL TOOLS

The following special tools are required to service

the genset. See the Onan Tool Catalog.

Engine Tools

Torque wrench (0-75 lbs-ft or 0-100 N-m)

Feeler gauge

Leak down tester

Spark plug gap gauge

Cylinder compression tester

Flywheel puller

Snap ring pliers

Cylinder ridge reamer

Piston ring compressor

Piston ring spreader

Cylinder hone

Valve seat cutter

Valve spring compressor

Piston groove cleaner

Outside micrometer set (1-4 in.)

Telescoping gauge set (0.500-4.000 in.)

Hole gauge (0.300-0.400 in.)

Plasti-Gage bearing clearance guide

Loading...

Loading...