10-1

10. Hydraulic Pump

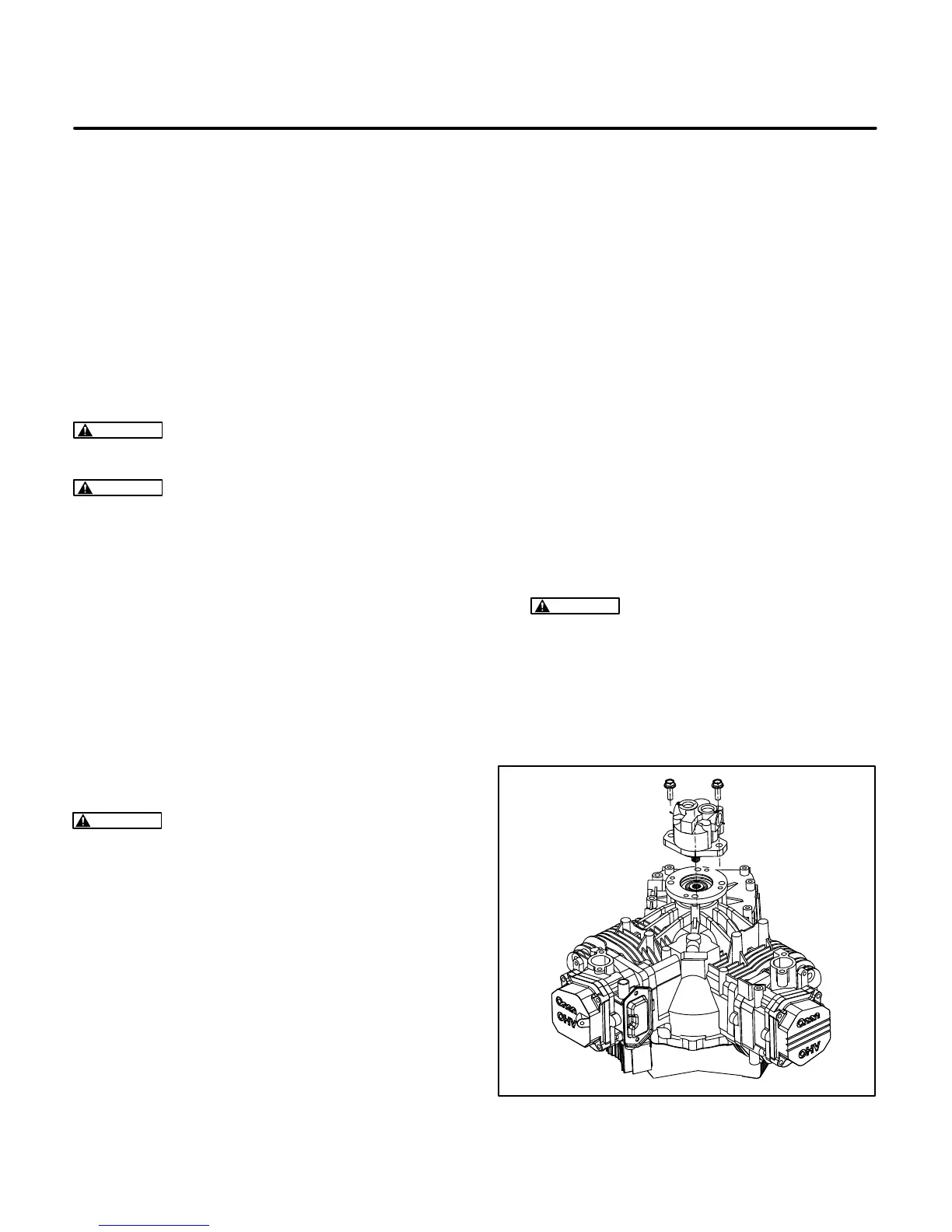

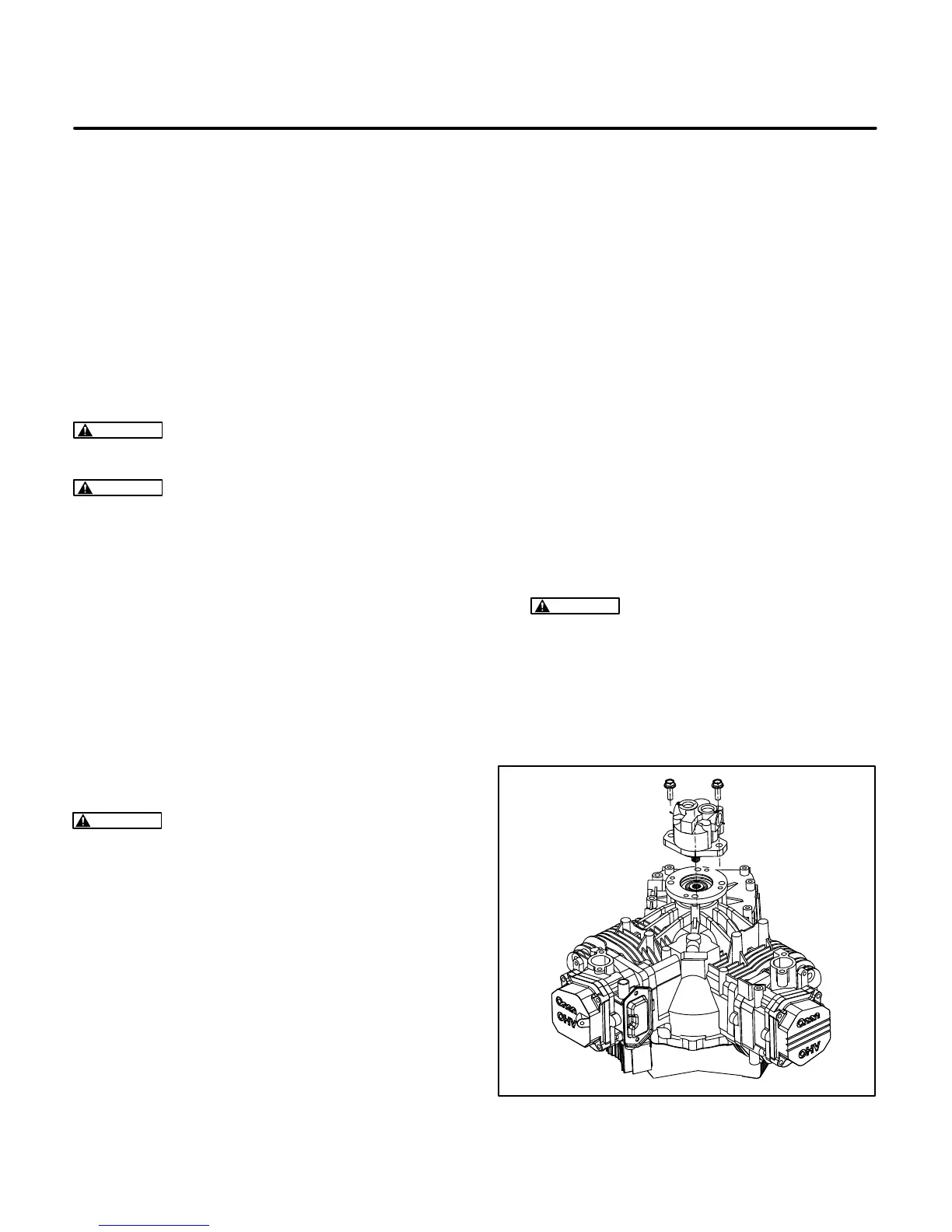

The optional hydraulic pump, when provided, is

mounted atop the engine (Figure 10-1). See Sec-

tion 13. Specifications regarding hose fittings, fluid

specifications and inlet conditions.

INSTALLING THE HYDRAULIC PUMP

When installing the pump, apply molybdenum disul-

fide paste or equivalent to the shaft spline and

torque the two flange screws to 20 lb-ft (26 N-m).

Do not start the genset before the hydraulic pump

has been connected to the hydraulic system and

filled with oil.

CAUTION

Running the genset without oil in

the hydraulic pump will destroy the pump.

CAUTION

The slightest amount of dirt in an

hydraulic system can damage precisely ma-

chined internal components. Keep dirt out:

• Thoroughly clean the outside of a fitting or

cap before disconnecting or removing it.

• Keep all openings in components and

hoses capped with proper JIC caps until

just before making connections.

• Thoroughly flush hoses before connecting.

• Regularly replace the oil filter.

• Never reuse hydraulic fluid that has been

drained from a system.

CONNECTING HYDRAULIC HOSES

WARNING

The high pressure spray from a leak

or fitting in a hydraulic line can penetrate the

skin, leading to possible blood poisoning —

Wear safety glasses — Shut down the genset

before loosening or tightening fittings — Do not

delay getting proper medical attention if ex-

posed to high pressure oil spray.

When connecting hoses and starting up the system:

1. Consider that hoses shrink slightly in length

and expand slightly in diameter under pres-

sure.

2. There must be enough slack in the connected

hoses to prevent strain due to movement of the

pump.

3. Support, restrain and protect hydraulic hose as

necessary to prevent chaffing.

4. Do not bend hose tighter than the hose

manufacturer recommends.

5. Use wide-sweep 90-degree fittings.

6. Always use two wrenches when tightening hy-

draulic fittings.

7. Install an SAE Class 4 filter (10 micron) in the

system.

8. The system oil reservoir should be above the

pump and the hose from the pump should slope

up to the reservoir.

9. To fill the pump, first fill the reservoir and crank

the engine with the spark plug cables discon-

nected from the spark plugs to prevent the en-

gine from starting. Replenish oil in the reservoir

as necessary.

10. The installed system must not cause pump inlet

conditions to exceed Specifications.

CAUTION

Continuing to run or load a

noisy pump can destroy it. Purge the air be-

fore continuing.

11. The hydraulic system has air in it as long as

there continues to be sharp metallic noise. Run

the genset for a few seconds at a time until all

air has been purged.

FIGURE 10-1. HYDRAULIC PUMP

Loading...

Loading...