4-12

Replacing Raw Water Pump Impeller

See Table 4-1 for scheduled replacement. Replace

the impeller as follows:

1. Close the sea valve.

2. Disconnect the negative (−) cable at the battery

to prevent the engine from starting.

WARNING

Accidental or remote starting

can cause severe personal injury or death.

Disconnect the negative (−) cable at the bat-

tery to prevent the engine from starting.

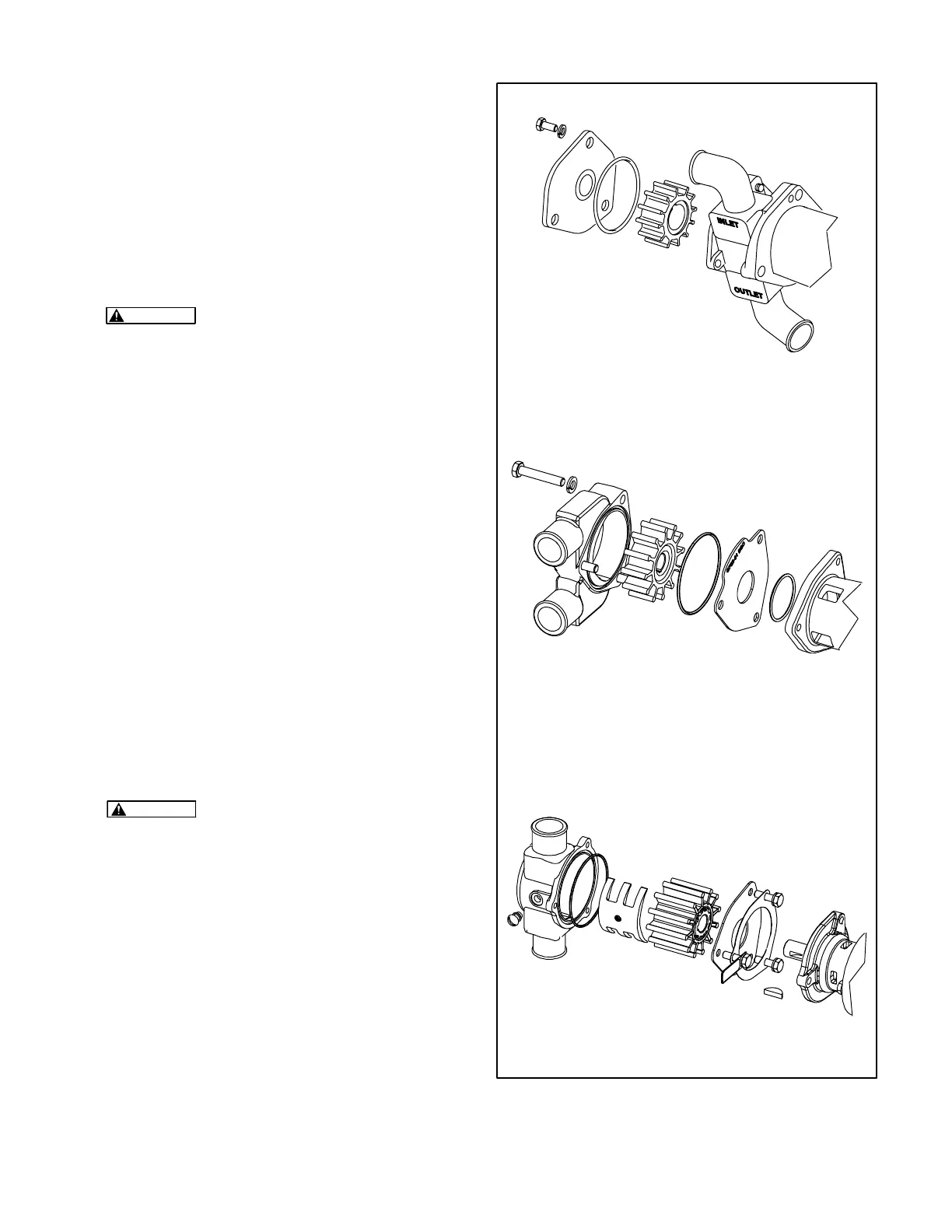

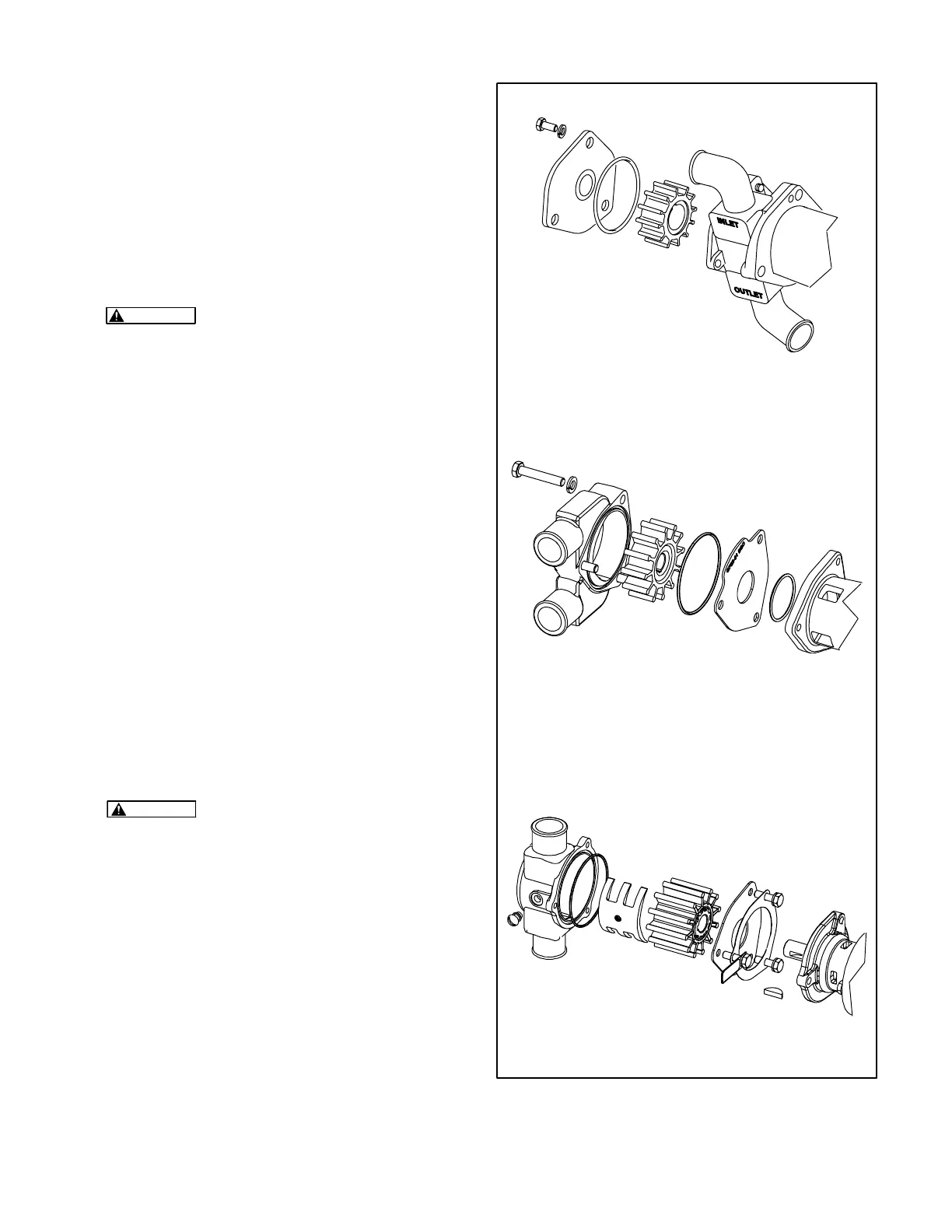

3. Loosen the three screws on the end of the

pump body to remove the pump body or impel-

ler cover, depending on construction (Fig-

ure 4-7).

4. Remove the impeller. An impeller removal tool

may be necessary to pull the impeller off the

shaft. Note: If vanes have broken off the impel-

ler, check for and cleanout pieces that may

have lodged in the heat exchanger.

5. Install the new impeller. To ease installation and

provide initial lubrication and better pump suc-

tion before water reaches the pump, wet the in-

side of the pump and impeller with water, soap

solution or a silicone lubricant. It also helps to

twist the impeller while squeezing it into the

housing.

CAUTION

Do not lubricate the impeller

with grease or oil or other petroleum prod-

ucts because they are known to chemically

attack impeller materials.

6. Secure the cover or pump body and O-ring.

7. Fill the sea water strainer for faster priming at

startup if it is above the water line.

8. Open the sea valve, reconnect the battery

cables (negative [−] last) and start the genset.

The genset will shut down within a few seconds

if there is no raw water flow and Fault Code

No. 7 (p. 9-5) will be declared. If it shuts down,

find out why, remove any blockage and restart

the genset.

MDKBP, MDKBR, MDKBS

MDKBK, MDKBL, MDKBM, MDKBN

MDKBT, MDKBU

FIGURE 4-7. TYPICAL RAW WATER PUMPS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...