COOLING

SYSTEM

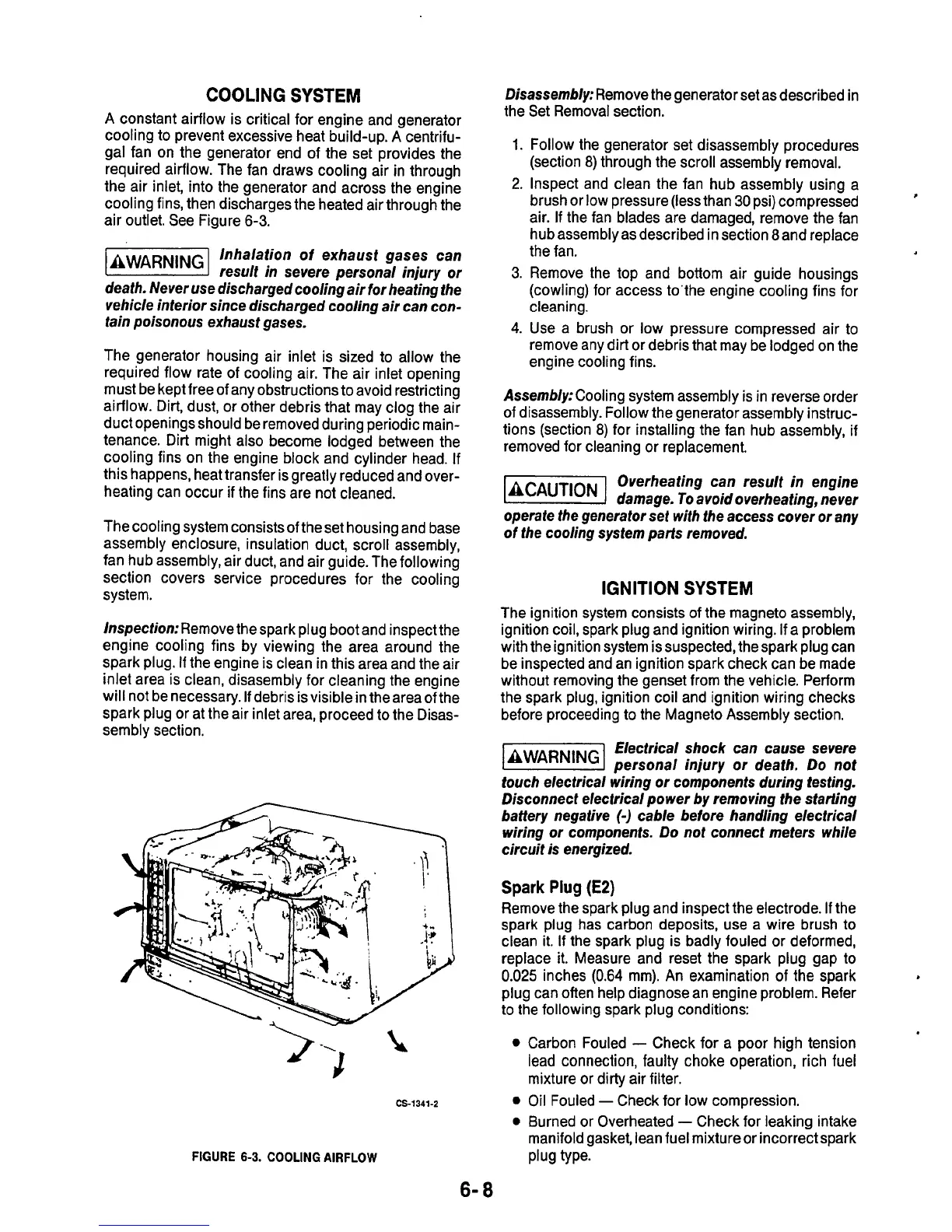

A

constant airflow is critical for engine and generator

cooling to prevent excessive heat build-up.

A

centrifu-

gal fan on the generator end of the set provides the

required airflow. The fan draws cooling air in through

the air inlet, into the generator and across the engine

cooling fins, then discharges the heated air through the

air outlet. See Figure

6-3.

Inhalation of exhaust gases can

EiEEEGI

result in severe personal injury

or

death. Never use discharged cooling air for heating the

vehicle interior since discharged cooling air can con-

tain poisonous exhaust gases.

The generator housing air inlet is sized to allow the

required flow rate of cooling air. The air inlet opening

must be kept free of any obstructions to avoid restricting

airflow. Dirt, dust, or other debris that may clog the air

duct openings should be removed during periodic main-

tenance. Dirt might also become lodged between the

cooling fins on the engine block and cylinder head.

If

this happens, heat transfer is greatly reduced and over-

heating can occur

if

the fins are not cleaned.

The cooling system consists of the set housing and base

assembly enclosure, insulation duct, scroll assembly,

fan hub assembly, air duct, and air guide. The following

section covers service procedures for the cooling

system.

Disassembly:

Remove the generator set as described in

the Set Removal section.

1.

2.

3.

4.

Follow the generator set disassembly procedures

(section 8) through the scroll assembly removal.

Inspect and clean the fan hub assembly using a

brush or low pressure (less than

30

psi) compressed

air.

If

the fan blades are damaged, remove the fan

hub assembly as described in section 8and replace

the fan.

Remove the top and bottom air guide housings

(cowling) for access to’the engine cooling fins for

cleaning.

Use a brush or low pressure compressed air

to

remove any dirt or debris that may be lodged on the

engine cooling fins.

?

1nspection:Remove

the spark plug boot and inspect the

engine cooling fins by viewing the area around the

spark plug.

If

the engine is clean in this area and the air

inlet area is clean, disasembly for cleaning the engine

will not be necessary.

If

debris is visible in the area of the

spark plug or at the air inlet area, proceed

to

the Disas-

sembly section.

Spark

Plug

(E2)

Remove the spark plug and inspect the electrode.

If

the

spark plug has carbon deposits, use a wire brush

to

clean

it.

If

the spark plug is badly fouled or deformed,

replace it. Measure and reset the spark plug gap

to

0.025

inches

(0.64

mm). An examination of the spark

plug can often help diagnose an engine problem. Refer

to the following spark plug conditions:

.

Assembly:

Cooling system assembly is in reverse order

of disassembly. Follow the generator assembly instruc-

tions (section 8) for installing the fan hub assembly, if

removed for cleaning or replacement.

Overheating can result in engine

damage.

To

avoid overheating, never

operate the generator set with the access cover

or

any

of

the cooling system parts removed.

IGNITION

SYSTEM

The ignition system consists of the magneto assembly,

ignition coil, spark plug and ignition wiring.

If

a problem

with the ignition system issuspected, the spark plug can

be inspected and an ignition spark check can be made

without removing the genset from the vehicle. Perform

the spark plug, ignition coil and ignition wiring checks

before proceeding to the Magneto Assembly section.

Electrical shock can cause severe

personal injury or death. Do not

touch electrical wiring

or

components during testing.

Disconnect electrical power by removing the starting

battery negative

(-1

cable before handling electrical

wiring

or

components. Do not connect meters while

circuit is energized.

>

-----

t

CS-1341-2

FIGURE

6-3.

COOLING

AIRFLOW

Carbon Fouled

-

Check for a poor high tension

lead connection, faulty choke operation, rich fuel

mixture or dirty air filter.

Oil Fouled

-

Check for low compression.

Burned or Overheated

-

Check for leaking intake

manifold gasket, lean fuel mixture or incorrect spark

Plug type-

6-

8

Loading...

Loading...