TIMING GEARS

If

replacement of either the crankshaft gear or the cam-

shaft gear becomes necessary,

it

is recommended that

both gears be replaced. Each

of

these gears are

pressed on. The crankshaft gear requires agear separa-

tor and puller to remove and the camshaft gear requires

a press

to

remove. Both gears can be installed using a

press. These gears use a Woodruff key

to

provide cor-

rect positioning on the shaft.

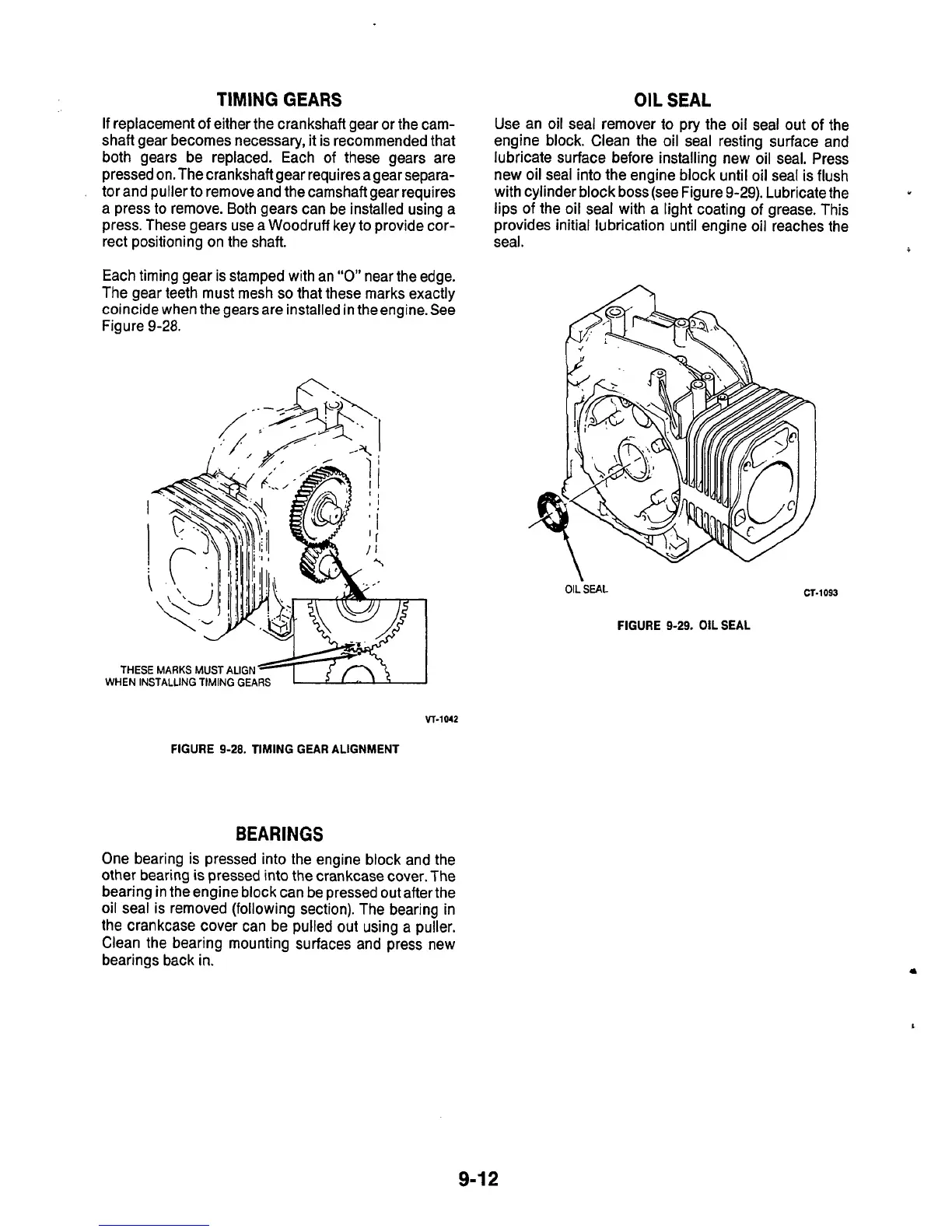

Each timing gear is stamped with an

“0”

near the edge.

The gear teeth must mesh

so

that these marks exactly

coincide when the gears are installed in theengine-See

Figure

9-28.

rc\

..

VI-1042

FIGURE

9-28.

TIMING GEAR ALIGNMENT

BEARINGS

One bearing is pressed into the engine block and the

other bearing

is

pressed into the crankcase cover. The

bearing in the engine block can be pressed out after the

oil seal is removed (following section). The bearing in

the crankcase cover can be pulled out using a puller.

Clean the bearing mounting surfaces and press new

bearings back in.

OIL

SEAL

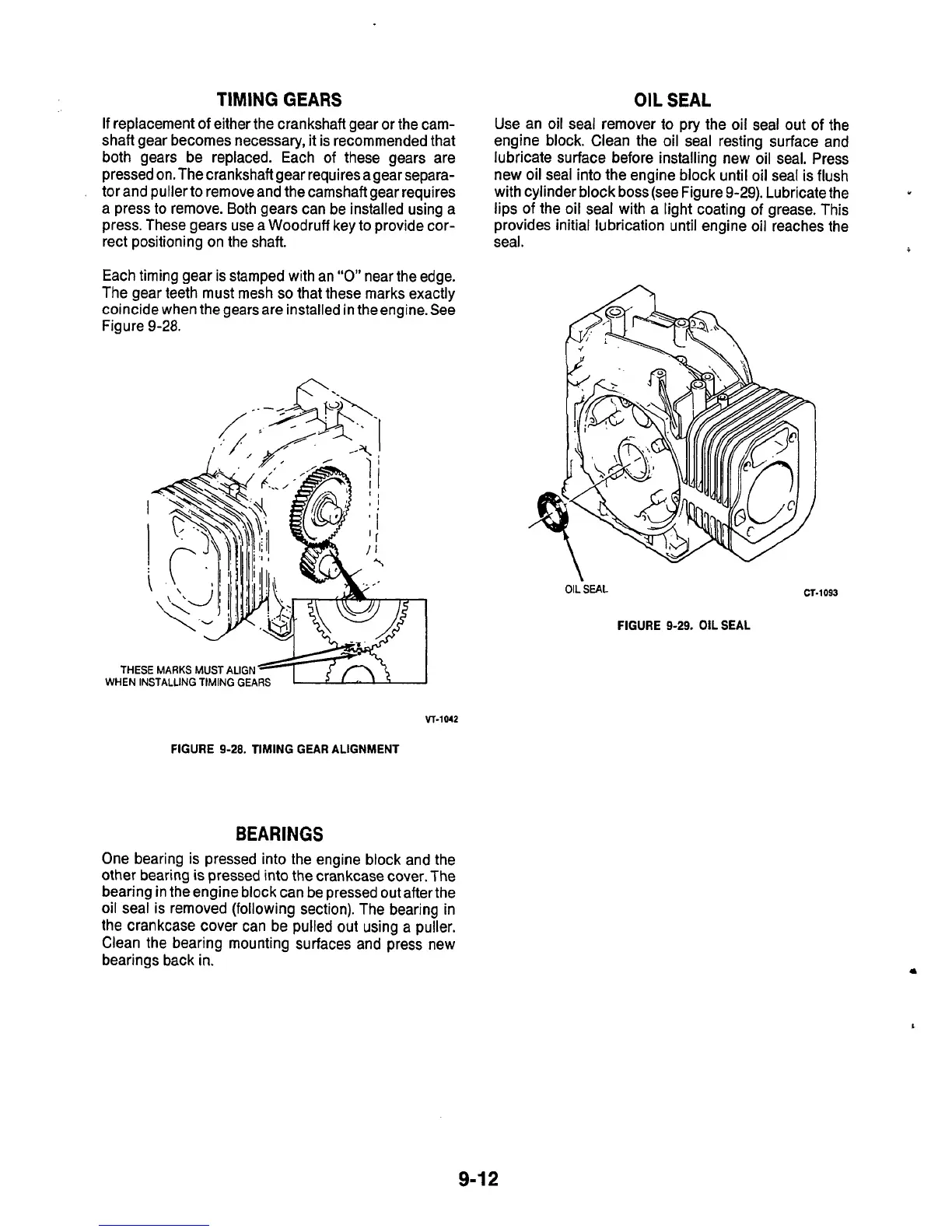

Use an oil seal remover to pry the oil seal out of the

engine block. Clean the oil seal resting surface and

lubricate surface before installing new oil seal. Press

new oil seal into the engine block until

oil

seal

is flush

with cylinder block boss (see Figure

9-29).

Lubricate the

lips

of

the oil seal with a light coating of grease. This

provides initial lubrication until engine oil reaches the

seal.

c

\

OIL

SEAL

‘3-1093

FIGURE

9-29.

OIL

SEAL

9-1

2

Loading...

Loading...