Careless handling of the stator can

damage the insulation

on

the stator

windings.

Do

Not brush windings against the hous-

ing or strike windings during installation.

5.

Align slot in rotor shaft with Woodruff key on crank-

shaft and lower rotor onto crankshaft. Make sure

that the rotor is seated.

Misalignment

of

the rotor shaft

and the crankshaft can cause

damage to the rotor and stator assembly.Use care

when installing the rotor shaft

to

align the crank-

shaft and rotor shaft with the Woodruff key in the

crankshaft.

6. Attach the stator wire harness connectors

to

the

stator. Be careful not

to

bend connector terminals or

damage may occur. Refer to Figures 8-1 and

8-2

for

wiring locations. Use wire ties

to

secure stator leads

away from rotor and fan hub

to

prevent rubbing.

7.

Prepare endbell for installation. Place springs on

studs and lubricate O-ring. Verify that brushes are

held in holder with piece of wire. See Figure 8-6.

Install endbell onto rotor bearing and secure with

endbell mounting screws.

The brushes will be damaged

@@%@I

during assembly if not held

off

the slip rings. Make certain wire is in place before

installing the generator endbell.

8. Remove the piece

of

wire holding the brushes

off

the slip rings. Connect the F- lead wire

to

the

out-

board brush terminal and the F+ lead wire to the

inboard brush terminal.

9.

Install fan hub onto rotor shaft and align key slot on

fan hub with key slot in end

of

rotor shaft. Install

alignment key. Insert washer on rotor through-bolt

and install into rotor shaft. Verify alignment of rotor

shaft and fan hub. Use special tool

to

secure fan hub

assembly (Figure

8-4)

and tighten the rotorthrough-

bolt

to

the specified torque.

Leaking fuel will create a fire

hazard which can result in.

severe personal injury or death.

If

leaks are

detected correct immediately. Replace worn fuel

line components before leaks occur.

15.

Connect the

B+

lead to the start solenoid. Attach

K3

relay

to

the inlet baffle assembly (Figure

7-3).

16.

Install the control panel. Inspect assembly, check all

electrical and mechanical connections for correct

fit and location. Place enclosure cover on set and

secure with side mounting screws.

17.

Install the generator set in the vehicle and securely

fasten all mounting screws and hardware. Connect

the fuel line, exhaust system and electrical systems

in reverse order

of

disassembly. Refer

to

Set Remo-

val (section

5).

18.

Fill crankcase with oil of the recommended classifi-

cation and viscosity.

BRUSHES

AND

SLIP

RINGS

This section covers brush replacement and slip ring

service.

Brush

Replacement

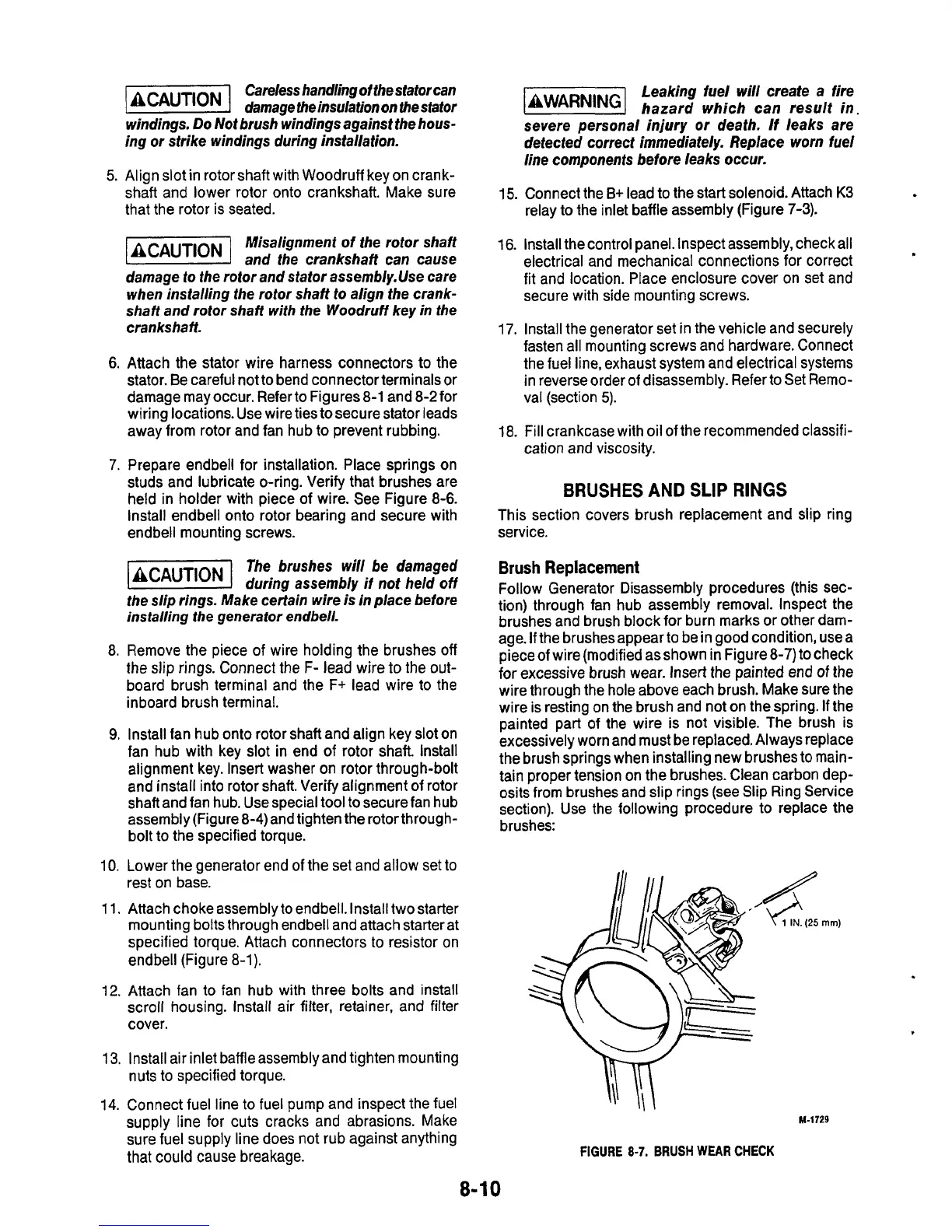

Follow Generator Disassembly procedures (this sec-

tion) through fan hub assembly removal. Inspect the

brushes and brush block for burn marks or other dam-

age.

If

the brushes appear

to

be in good condition, use a

piece

of

wire (modified as shown in Figure

8-7)

to check

for

excessive brush wear. Insert the painted end

of

the

wire through the hole above each brush. Make sure the

wire is resting on the brush and not on the spring.

If

the

painted part of the wire is not visible. The brush is

excessively worn and must be replaced. Always replace

the brush springs when installing new brushes

to

main-

tain proper tension on the brushes. Clean carbon dep-

osits from brushes and slip rings (see Slip Ring Service

section). Use the following procedure

to

replace the

brushes:

10. Lower the generator end

of

the set and allow set to

rest on base.

11.

Attach choke assembly

to

endbell. Install two starter

mounting

bolts

through endbell and attach starter at

specified torque. Attach connectors

to

resistor on

endbell (Figure

8-1).

12.

Attach fan

to

fan hub with three bolts and install

scroll housing. Install air filter, retainer, and filter

cover.

13.

Install air inlet baffle assembly and tighten mounting

14.

Connect fuel line to fuel pump and inspect the fuel

sure fuel supply line does not rub against anything

that

could cause breakage.

nuts

to

specified torque.

supply line for cuts cracks and abrasions. Make

M-1729

FIGURE

8-7.

BRUSH

WEAR

CHECK

8-1

0

Loading...

Loading...