LPG

FUEL

SYSTEM

The LPG-fueled models use a low-pressure vapor

withdrawal system that must be properly adjusted and

be in good working condition. Components unique

to

the fuel system are:

Demand Regulator with Automatic Priming

Solenoid

0

LPG Carburetor

0

Fuel Solenoid

Special precautions must be taken to avoid releasing

large quantities of highly flammable

LP

gas when servic-

ing the fuel system. Use the LP gas purging procedure

described in the

Preparing

to

Service

section

to

purge

the fuel system of LP gas before servicing any fuel

system components.

The fuel supply line pressure to the demand regulator must be in the

range

of

6

to

B

ounces per square inch

(10

to

14

inches

of

water

column).

The fuel supply line from the primary regulator to the

generator set fuel system components must be dedi-

cated

to

the generator set only and not shared with any

appliances.

[-I

LP gas presents the hazard of fire

or

explosion and

it

is poisonous. These

hazards can result in severe personal injury

or

death. If

flameout occurs with an unvented appliance, LP gas

can accumulate inside the vehicle and create a safety

hazard. If the generator set tuel supply line

is

shared

with any appliance, do not continue with any further

service procedures. Correct as necessary to comply

with applicable codes before continuing service

work.

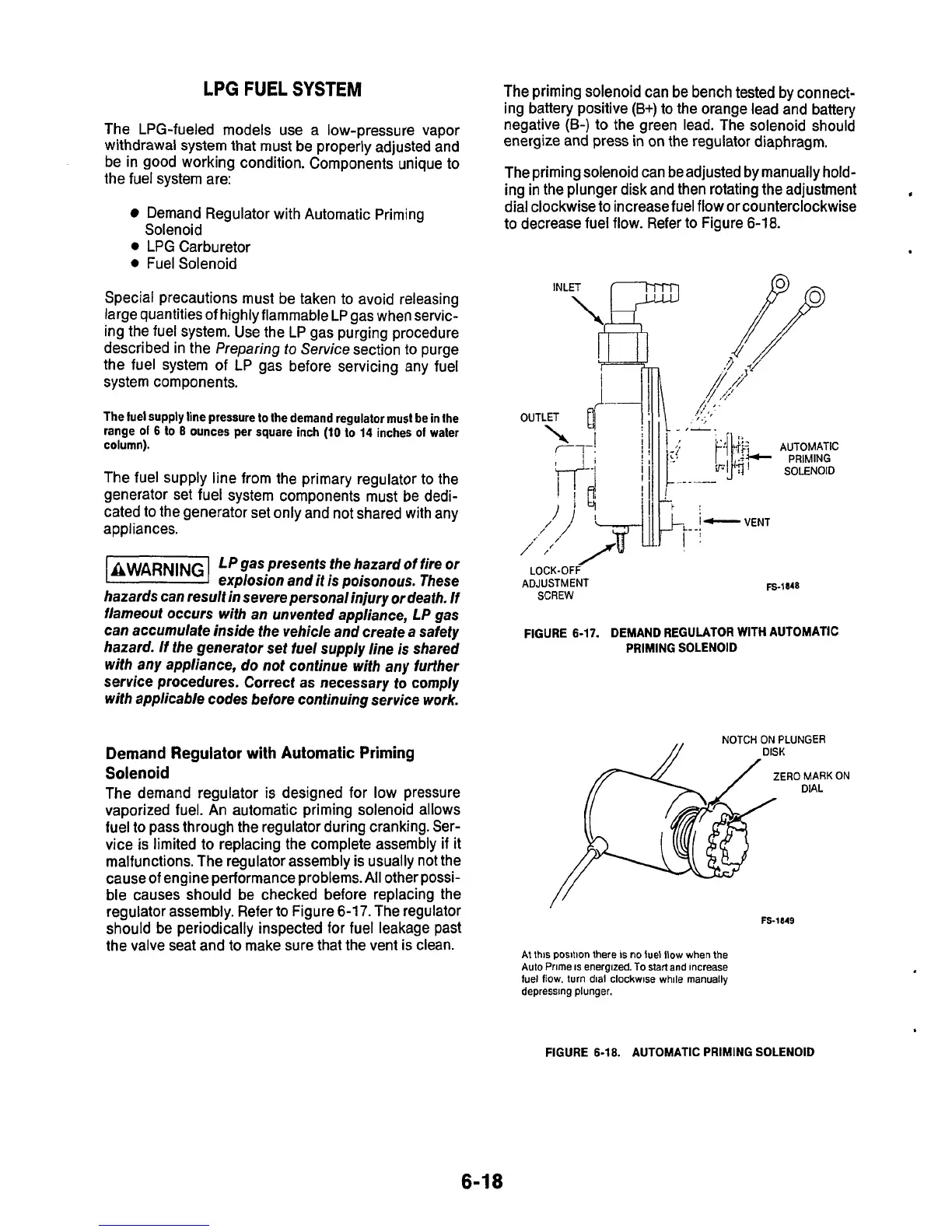

Demand

Regulator with Automatic Priming

Solenoid

The demand regulator is designed for low pressure

vaporized fuel. An automatic priming solenoid allows

fuel to pass through the regulator during cranking. Ser-

vice

is

limited to replacing the complete assembly

if

it

malfunctions. The regulator assembly is usually not the

cause

of

engine performance problems.

All

other possi-

ble causes should be checked before replacing the

regulator assembly. Refer to Figure

6-17.

The regulator

should be periodically inspected for fuel leakage past

the valve seat and to make sure that the vent is clean.

The priming solenoid can be bench tested by connect-

ing battery positive

(B+)

to

the orange lead and battery

negative

(B-)

to the green lead. The solenoid should

energize and press in on the regulator diaphragm.

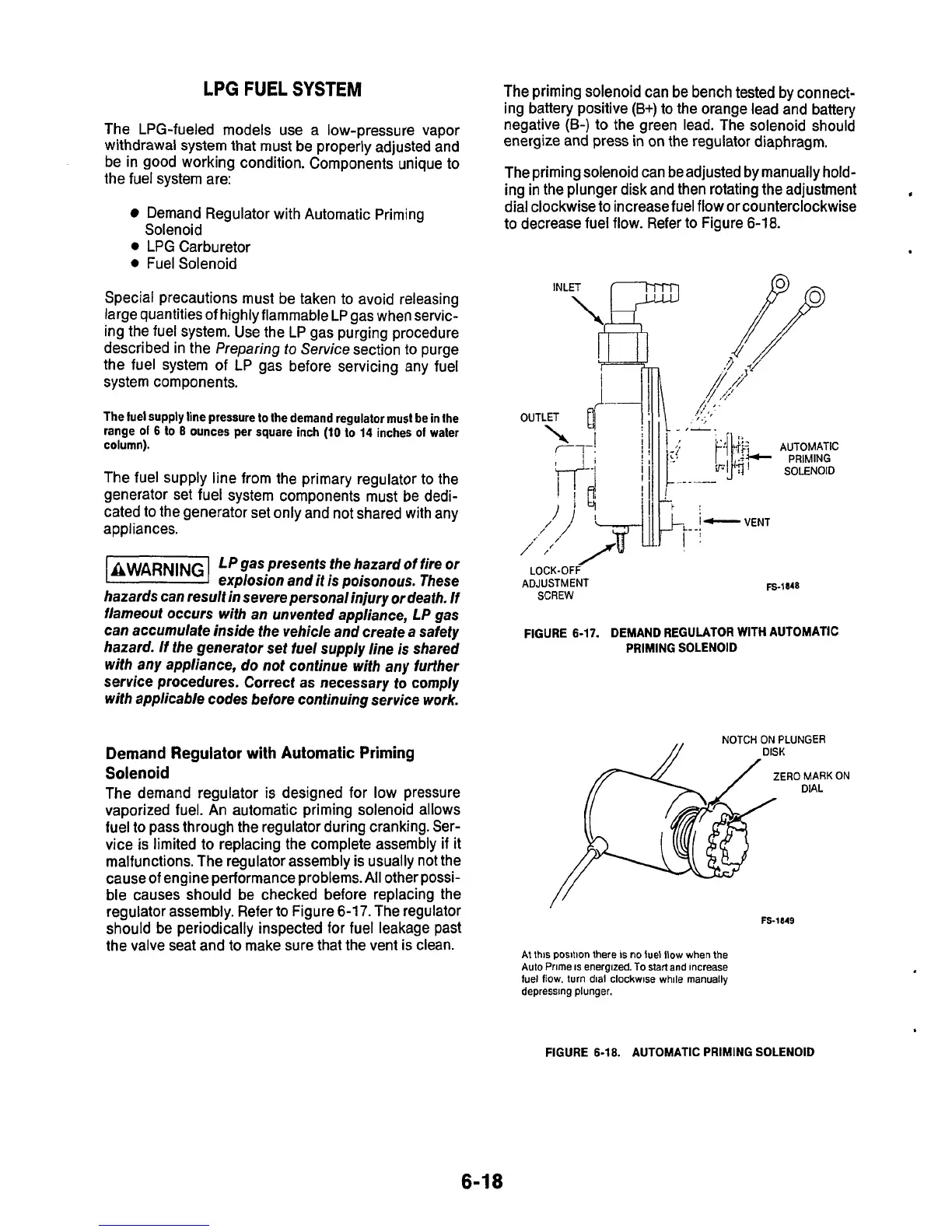

The priming solenoid can be adjusted by manually hold-

ing in the plunger disk and then rotating the adjustment

dial clockwise

to

increase fuel flow or counterclockwise

to decrease fuel flow. Refer

to

Figure

6-18.

OUTLET

D

I

AUTOMATIC

PRIMING

I

VENT

ADJUSTMENT

SCREW

Fs-1848

FIGURE

6-17.

DEMAND

REGULATOR

WITH

AUTOMATIC

PRIMING

SOLENOID

NOTCH ON PLUNGER

ZERO MARK

ON

DIAL

FS-1849

At this position there

is

no

iuel

flow

when

the

Aulo

Prime is energized.

To

start and increase

iuel flow.

turn

dial clockwise while manually

depressing plunger.

FIGURE

6-18.

AUTOMATIC

PRIMING

SOLENOID

6-1

8

Loading...

Loading...