Assembly

Torques

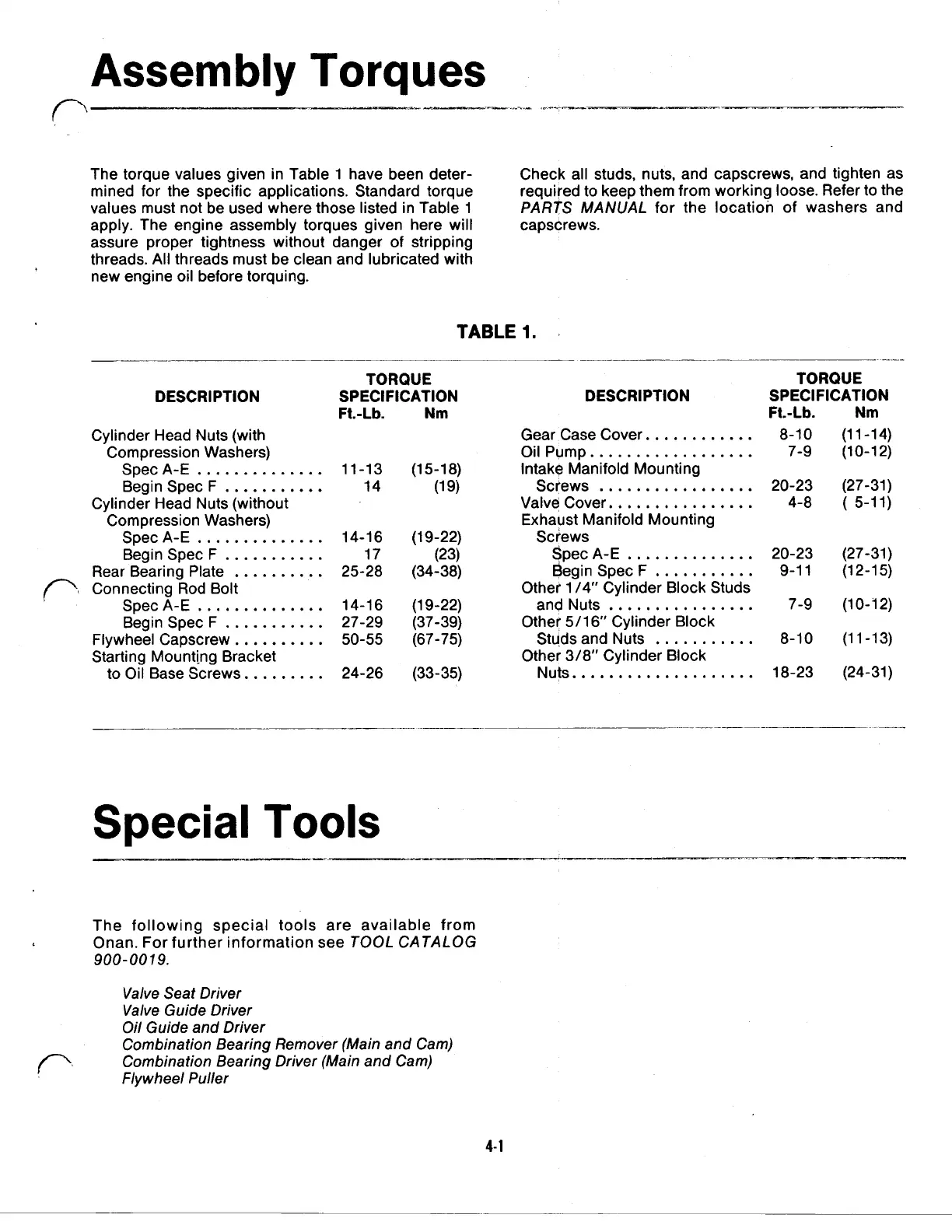

The torque values given in Table 1 have been deter- Check all studs, nuts, and capscrews, and tighten as

mined for the specific applications. Standard torque required to keep them from working loose. Refer to the

values must not be used where those listed in Table

1

PARTS MANUAL

for the location

of

washers and

apply. The engine assembly torques given here will capscrews.

assure proper tightness without danger

of

stripping

threads.

All

threads must be clean and lubricated with

new engine oil before torquing.

DESCRIPTION

Cylinder Head Nuts (with

Compression Washers)

SpecA-E

Begin Spec F

Cylinder Head Nuts (without

Compression Washers)

SpecA-E

Rear Bearing Plate

Connecting Rod Bolt

SpecA-E

Begin Spec F

Flywheel Capscrew.

Starting Mounting Bracket

to Oil Base Screws.

Begin Spec F

TABLE

1.

TORQUE

SPECIFICATION DESCRIPTION

F1.-Lb. Nm

Gear Case Cover.

Oil Pump.

14

Valve Cover.

Exhaust Manifold Mounting

11-13 (15-18) Intake Manifold Mounting

(19) Screws

14-16 (19-22) Screws

17

25-28 (34-38) Begin Spec F

Other 1/4” /4" Cylinder Block Studs

(23) Spec

A-E

14-16 (1 9-22)

and Nuts

27-29 (37-39)

Other 5/16" Cylinder Block

50-55 (67-75)

Studs and Nuts

24-26 (33-35) Nuts.

Other 3/8” Cylinder Block

TORQUE

SPECIFICATION

F1.-Lb. Nm

8-10 (1 1-14)

7-9 (10-1 2)

(27-31)

4-8

(

5-11)

20-23

(27-31)

9-11

(12-15)

7-9 (10-72)

8-10 (1 1-13)

18-23 (24-31)

Special

Tools

The following special tools are available from

Onan. For further information see

TOOL CATALOG

900-0019.

Valve Seat Driver

Valve Guide Driver

Oil Guide and Driver

Combination Bearing Remover (Main and Cam)

Combination Bearing Driver (Main and Cam)

Flywheel Puller

4-1

Loading...

Loading...