Maintenance and Care

32

10 Maintenance and Care

10

.01 Maintenance intervals

Cleaning ........................................................ daily, several times if in continuous operation

Clean the hook area ...................................... daily, several times if in continuous operation

Clean the hook ..................................................................................... daily, before start-up

Check the hook oil reservoir..............................................................................once a week

General oiling .................................................................................................. twice a week

Oil the front parts ............................................................................................ twice a week

Checking / setting the air pressure ....................................................... daily, before start-up

Cleaning the maintenance unit air fi lter ............................................................... as needed

These maintenance intervals are based on an average running time of a single

shift production shop. Shorter maintenance intervals are recommended for

increased running times.

10.02 Cleaning the machine

The required cleaning cycle for the machine depends on the following factors:

Single or multi-shift operation

Dust formation caused by the workpieces

Optimal cleaning instructions can therefore only be determined on a case-by-case basis.

Disconnect the machine from the electricity mains for all cleaning work by

shutting off the main switch or removing the mains plug! Risk of injury due to

accidental machine start-up!

The following tasks are recommended

during single shift operation to avoid

operational errors:

Clean the hook area

Clean the hook area with a brush

Clean the hook

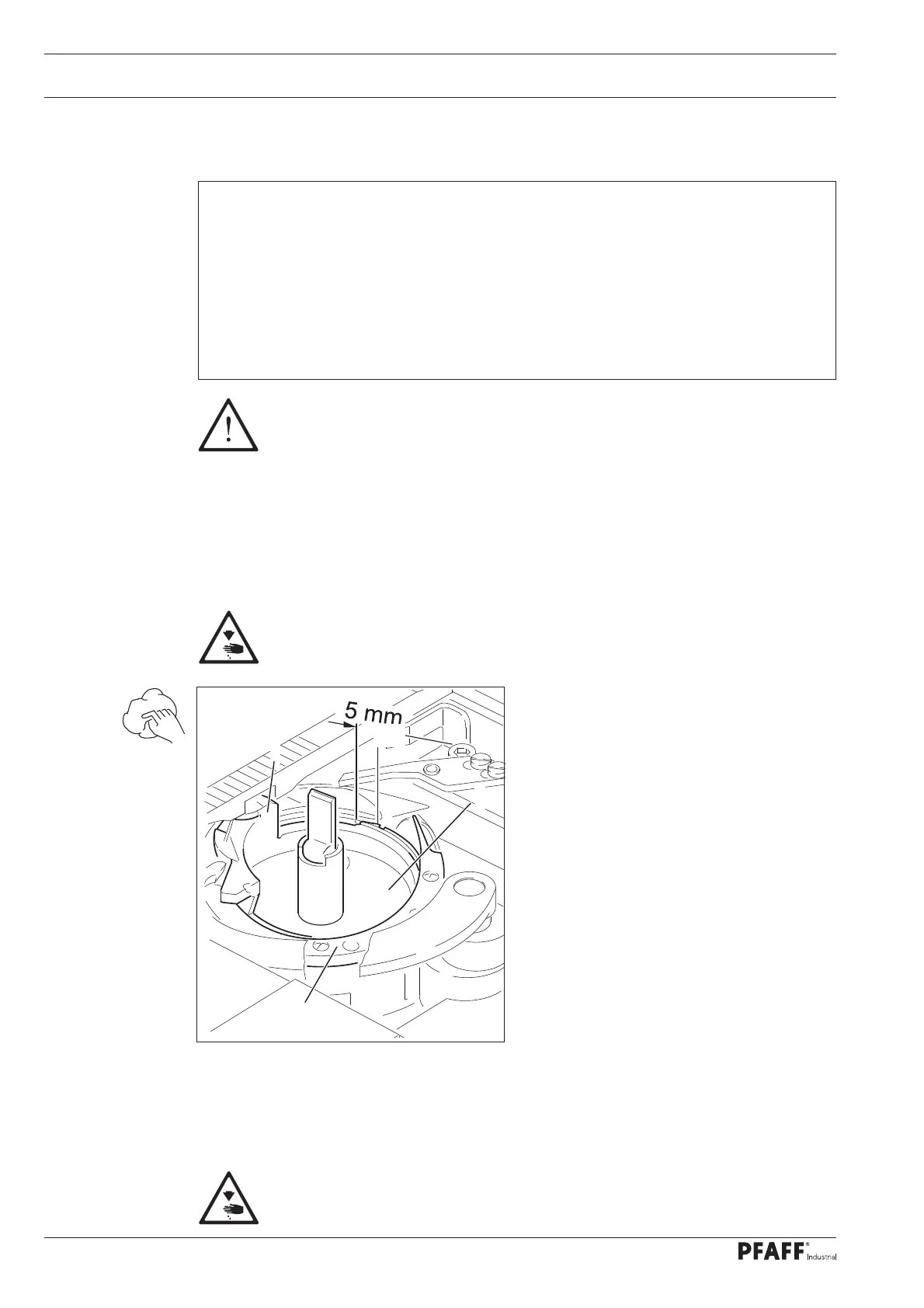

Open the hook area cover.

Bring the needle bar to the top position.

Remove the bobbin case sewing head

with bobbin.

Unscrew the hook gib 1.

Turn the handwheel until the tip of the

bobbin case 2 has penetrated approx.

5 mm into the groove of the hook race.

Remove the bobbin case and clean the

hook race with kerosene.

Make sure that the horn 3 engages in the groove of the stitch plate when inserting the

bobbin case.

Screw on the hook gib 1.

Insert the bobbin case with bobbin.

Close the hook area cover.

Always operate the machine when the hook area cover is closed!

Risk of injury from the rotating hook!

Fig. 10 - 01

1

2

3

5 mm

Loading...

Loading...