Refitting the head and timing system components

- Fix the head on a workbench.

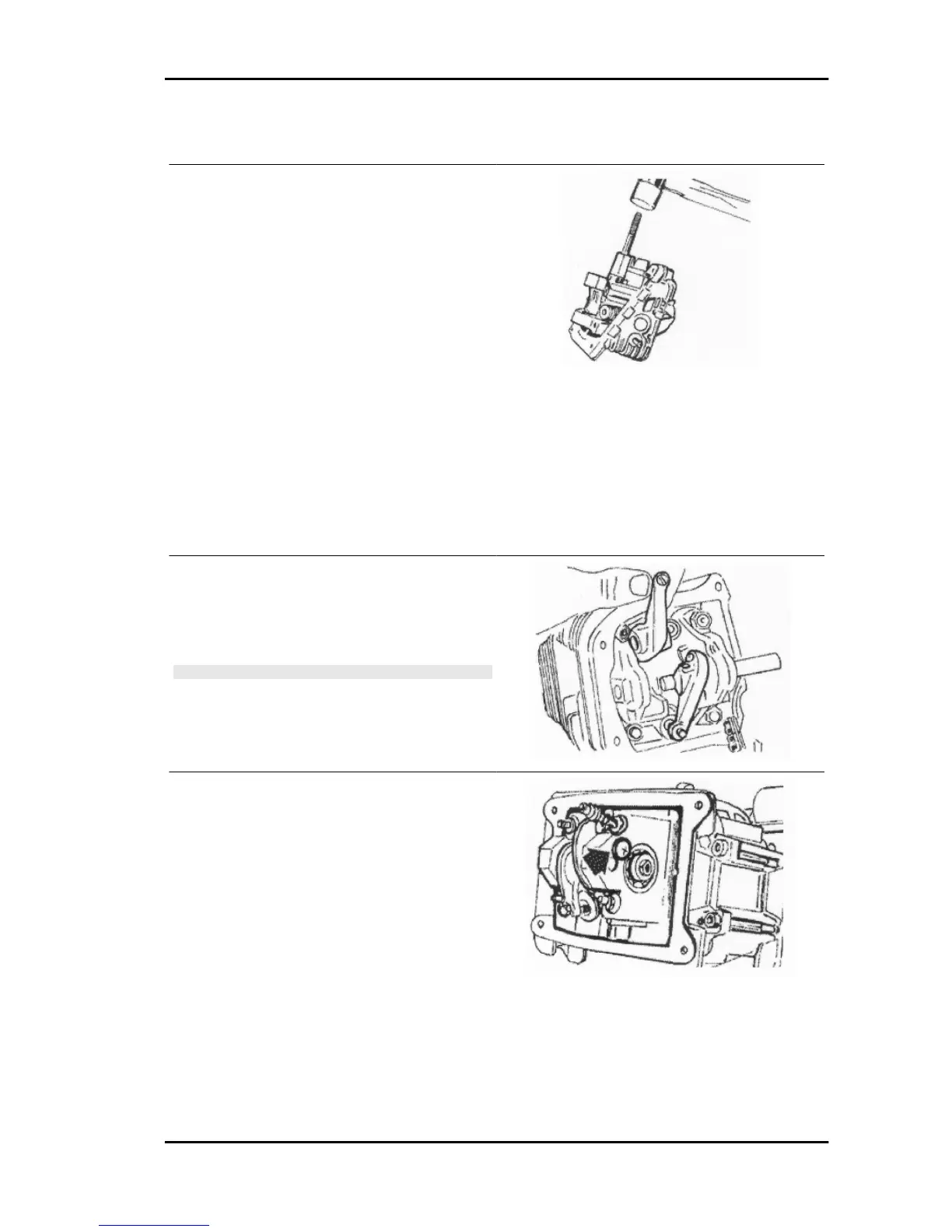

- Screw the tool to fit the camshaft fully down on

the bearing's inner track.

- Fit the camshaft fully into its seating together with

the bearing with the aid of a mallet.

- Remove the tool.

- Fit the head gasket after cleaning the faying sur-

face carefully.

- Insert the head in the cylinder stud bolts and

tighten the 4 fixing nuts to the prescribed torque.

Specific tooling

020450Y Camshaft fitting/removal tool

Locking torques (N*m)

Head-cylinder stud bolt nuts: 6 ÷ 7 +135° +90° Nm

first fitting, upon refitting tighten again at 6 ÷ 7 90° +90° Nm

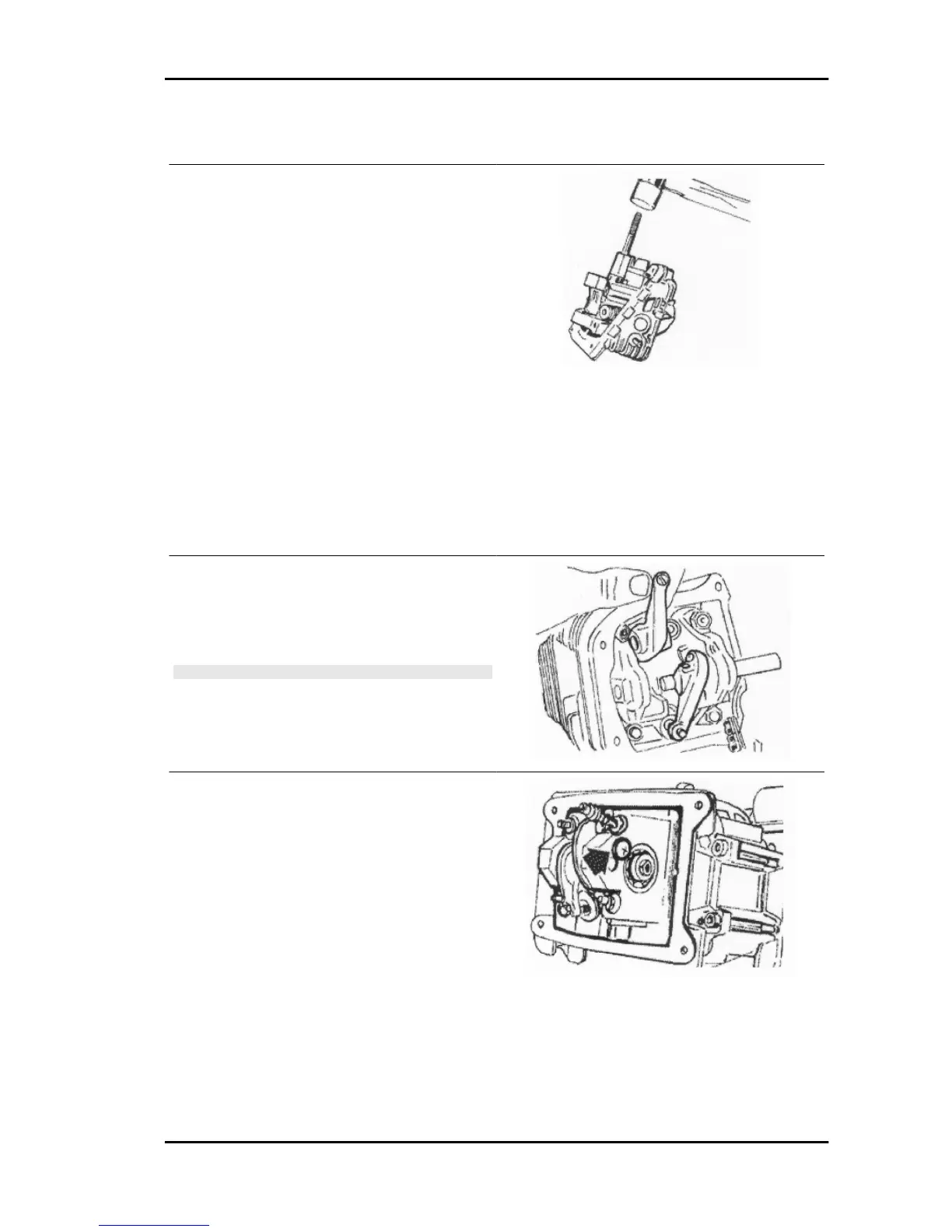

- Loosen the rocking lever registers.

- Fit the pin, the intake rocking lever and the dis-

charge rocking lever.

- Lubricate the 2 rocking levers through the holes.

N.B.

IF A BEARING SEPARATES FROM THE CAMSHAFT, IT IS

ESSENTIAL TO FIT A NEW BEARING.

- Screw the limit screw for the pin and the camshaft

with the washer indicated in the figure and tighten

it to the prescribed torque.

Locking torques (N*m)

Rocking lever axle and camshaft bearing

screw 3 ÷ 4 Nm

MSS ZIP 100 4T Engine

ENG - 103

Loading...

Loading...