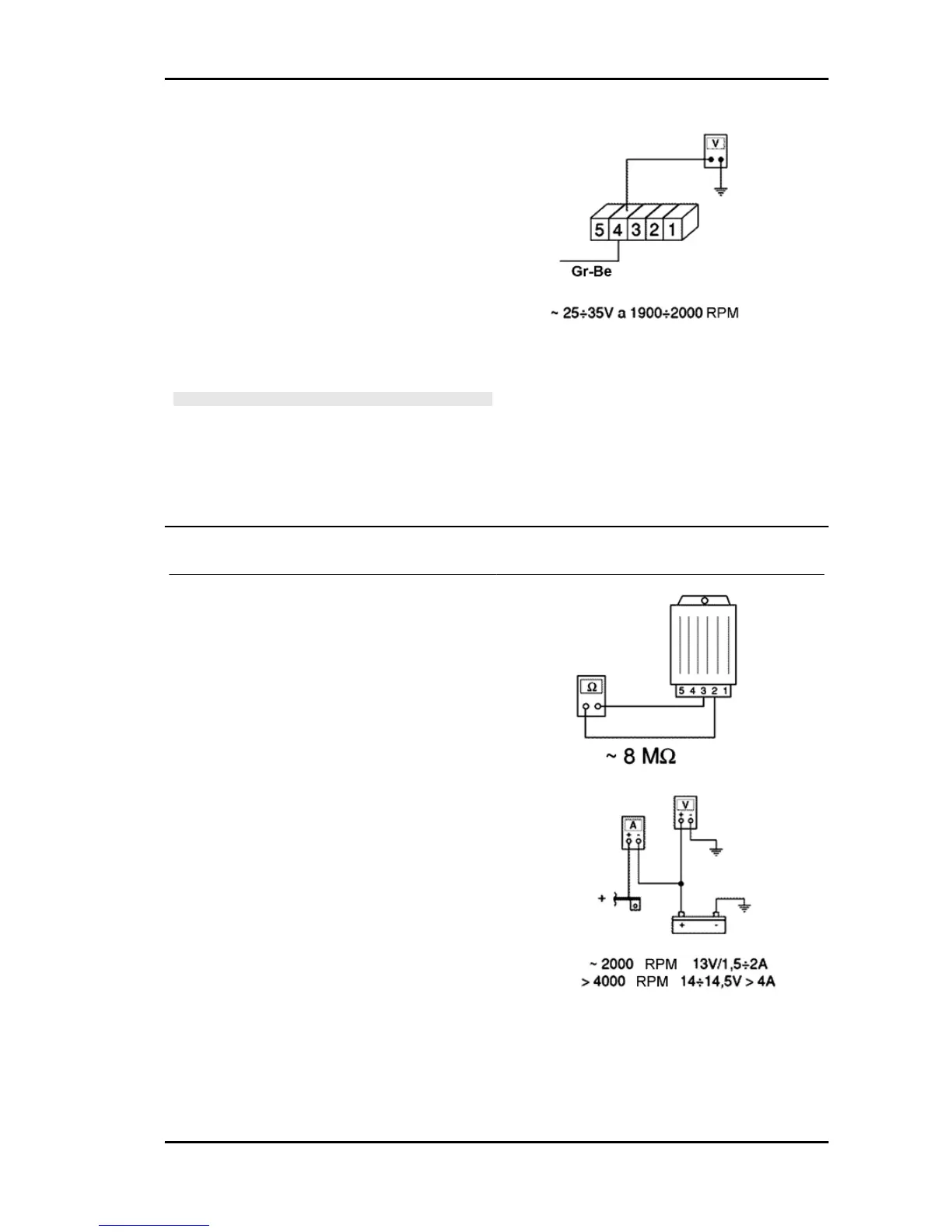

As a last check, the voltage supplied by the stator

can be measured:

- Disconnect the regulator connector and place a

tester between the Grey-Blue cable (4) and the

earth in order to detect alternating voltages (see

figure).

- Voltage supplied at 2000 rpm must be about 25

÷ 35V.

If no values are detected with this test, replace the

regulator because it is obviously broken.

N.B.

TO MEASURE THE ABOVE VOLTAGE USE AN ANALOGUE

TESTER THAT CAN MEASURE ALTERNATING VOLTAG-

ES AND KEEP THE ENGINE AT IDLE TO HAVE AN ALTER-

NATING VOLTAGE OF A FREQUENCY AS CLOSE AS

POSSIBLE TO 50HZ SO AS TO DETECT THE EFFICIENT

VOLTAGE VALUE SUPPLIED BY THE REGULATOR

(ABOUT 12V).

Recharge system voltage check

3) Battery fails to recharge

a failure in the direct current section of the voltage

regulator may cause the following problems de-

pending on the type of fault:

a) Protection fuse blows due to overvoltage

(regulator in short circuit) and consequently

the battery fails to recharge.

b) Battery fails to recharge (regulator interrup-

ted).

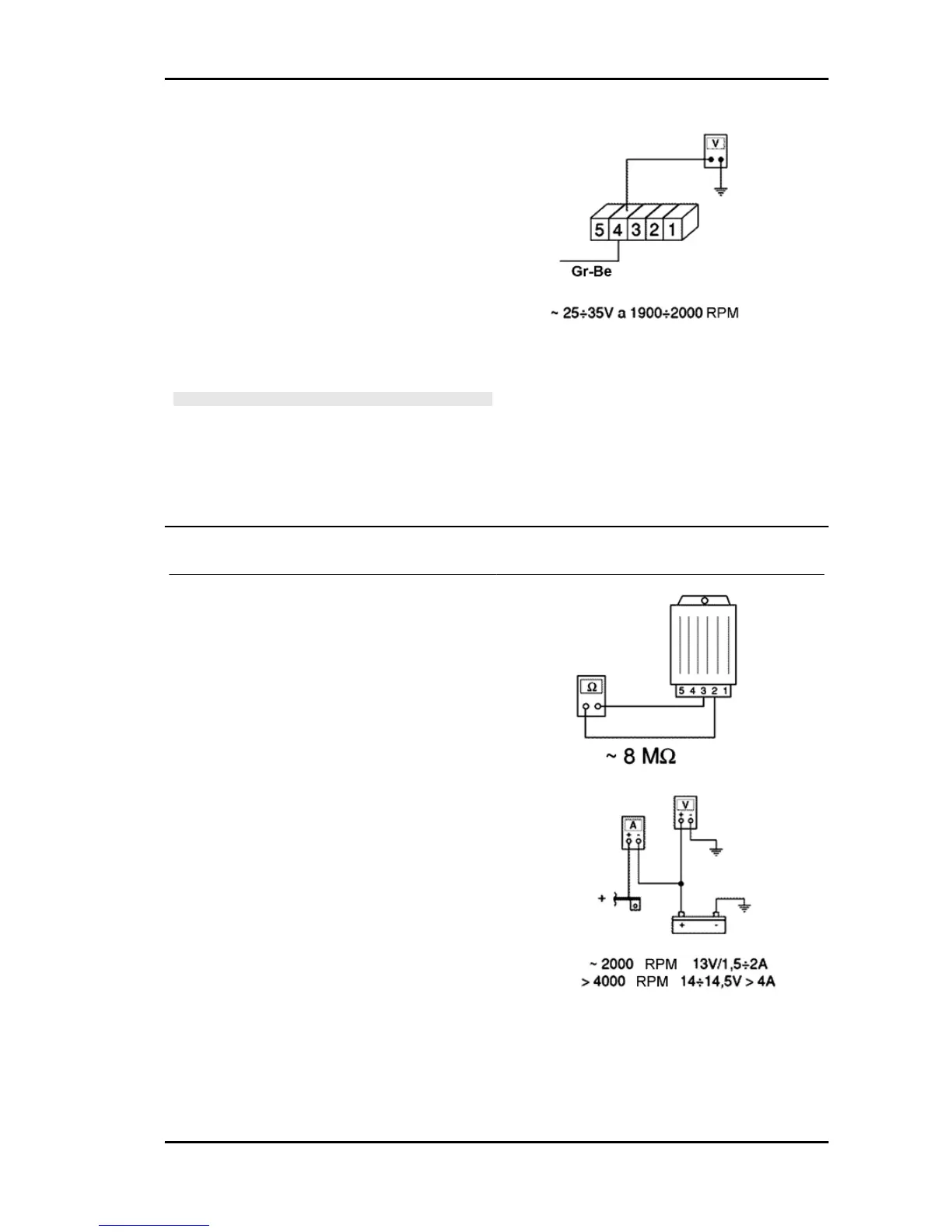

Measures

a) Protection fuse blows (regulator in short circuit).

Check that the wiring connecting the protection

fuse and the key switch is not damaged and caus-

ing a short circuit to the earth (thus excluding the

possibility that the regulator is damaged); if the

protection fuse blows only after the key switch is

set to "ON" and with the regulator connector dis-

connected, check that the upstream wiring and

devices of the key switch are not in short circuit to

the earth. Now measure the resistance between

contact 3 (White) and contact 2 (Black) of the volt-

MSS ZIP 100 4T Electrical system

ELE SYS - 57

Loading...

Loading...