Removing the oil sump

- Remove the oil filling cap, the transmission cover,

the complete driving pulley assembly with belt and

pinion.

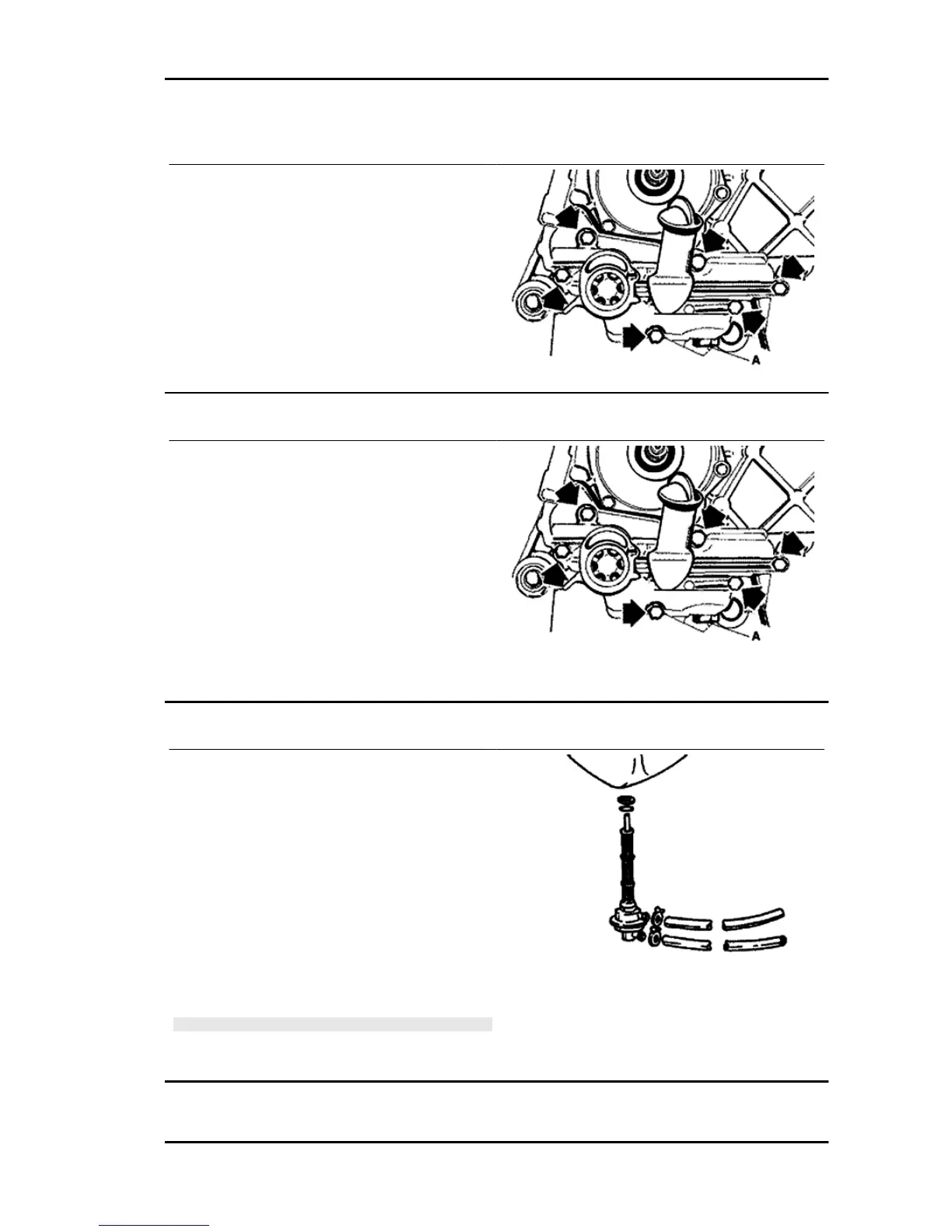

- Unscrew the oil drainage plug «A» shown in the

figure and drain out all the oil from the sump.

- Remove the 6 screws indicated in the figure.

Refitting the oil sump

- Clean and grease the faying surfaces.

- Apply LOCTITE 510 on the sump surface and

tighten the 6 fixing screws to the specified torque.

- Refit the driving pulley assembly, the belt, the

pinion and the transmission cover.

WHEN TESTING THE LUBRICATION SYSTEM, REFER TO

THE "CRANKCASE AND CRANKSHAFT" CHAPTER, RE-

GARDING LUBRICATION OF THE CRANKSHAFT AND

CONNECTING ROD

Locking torques (N*m)

Oil sump screws 8 ÷ 10 Nm

Fuel supply

- Completely empty the fuel tank.

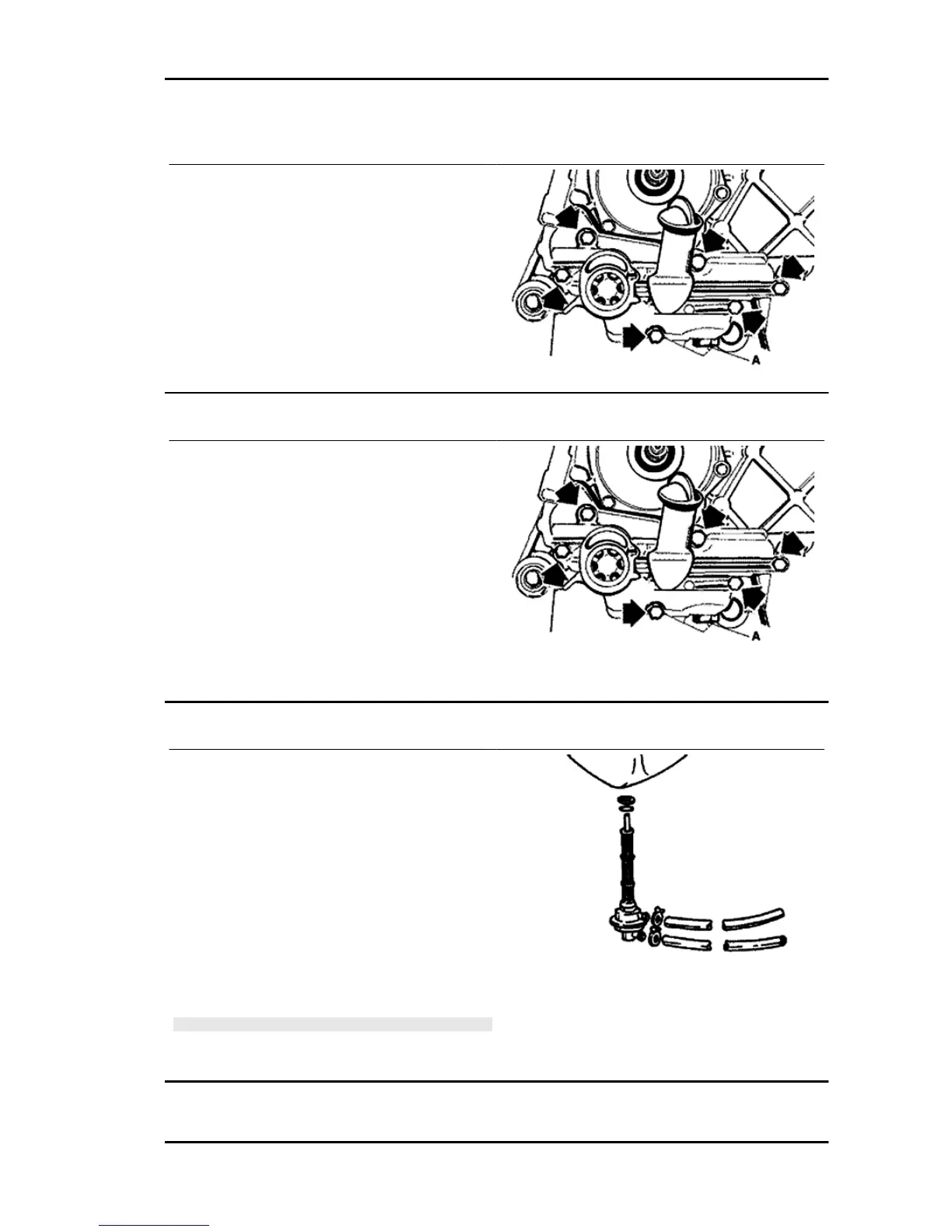

- Remove the petrol delivery pipe and the low-

pressure pipe.

- Loosen the clip and remove the cock.

- Clean the tank and the filter of the cock with a

specific solvent.

- Refit the cock making sure that there is an O-

Ring.

- Turn the cock to the direction it had before it was

removed and block the clip.

N.B.

THE FILTER CAN BE UNSCREWED FROM THE COCK TO

FACILITATE CLEANING.

MSS ZIP 100 4T Engine

ENG - 115

Loading...

Loading...