15

4.4 Refrigerant Line Set Selection (cont.)

4.0 INSTALLATION

Tubing

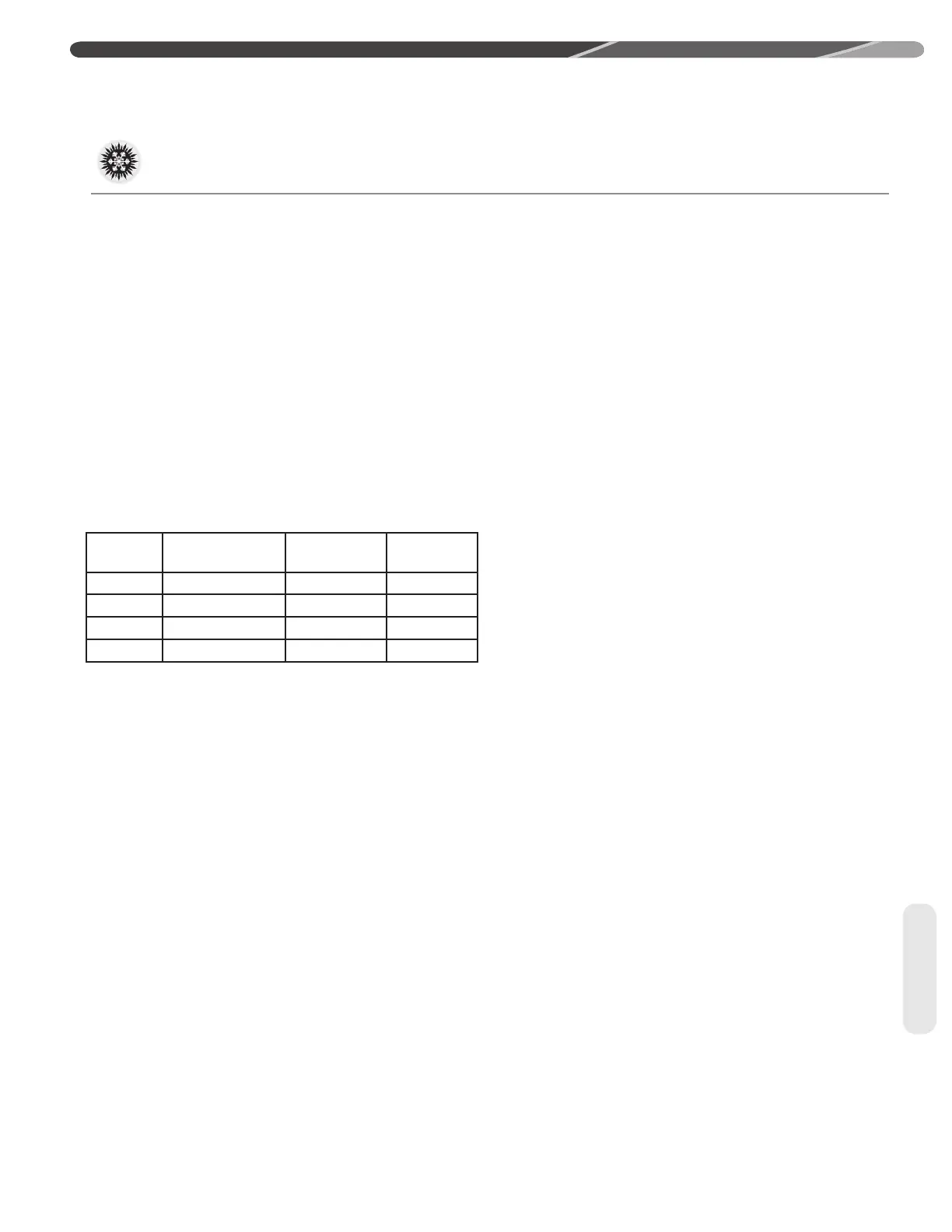

4.4.5.6 Compressor Oil Level

Adjustment for Long Line Set

Applications

Additional oil may need to be added for long line set

applications. (Ref. Table 2). Below is the equation for

the oil level adjustment. The compressor name plate

oil charge for the different outdoor units is shown in

the table to the right.

Oil to be Added = [(Charge Adjustment + OD Unit

Name Plate Charge (oz.)) × (0.022) – [(0.10) ×

(Compressor Name Plate Oil Charge (oz.))]

Example: An application requires 125 ft. of line set

with a liquid line diameter of 3/8”, Charge Adjustment

= 52.4 oz., Name Plate Charge = 107 oz., Name Plate

Oil Charge = 25 oz., Oil to be Added = ((52.4 oz. +107

oz.) × .022) – (.10 × 25 oz.) = 1.0 oz.

4.4.5.7 Capacity Losses

Long line lengths can result in a reduction in capacity

due to vapor line pressure drop and heat gain or loss.

Refer to Table 2 for capacity loss multipliers for vari-

ous vapor line diameters and lengths. Only use vapor

lines listed in Table 2 to assure proper oil return. This

table does not account for any capacity loss due to

heat gain or loss from the environment. It is extremely

important not to oversize the vapor line to minimize

capacity loss at the expense of proper oil return. If the

table shows an “NR” for a particular vapor line diame-

ter and length, capacity loss will be excessive. The full

length of the vapor line must be insulated to minimize

heat gain or loss.

Model

Number

Compressor

Name Plate Oil

Charge oz [ml]

Factory

Installed CCH

(-)A1724 ZPS20K5E-PFV-130 25 [739] N

(-)A1736 ZPS30K5E-PFV-130 25 [739] Y

(-)A1748 ZPS40K5E-PFV-130 42 [1242] Y

(-)A1760 ZPS49K5E-PFV-130 42 [1242] Y

Loading...

Loading...