42

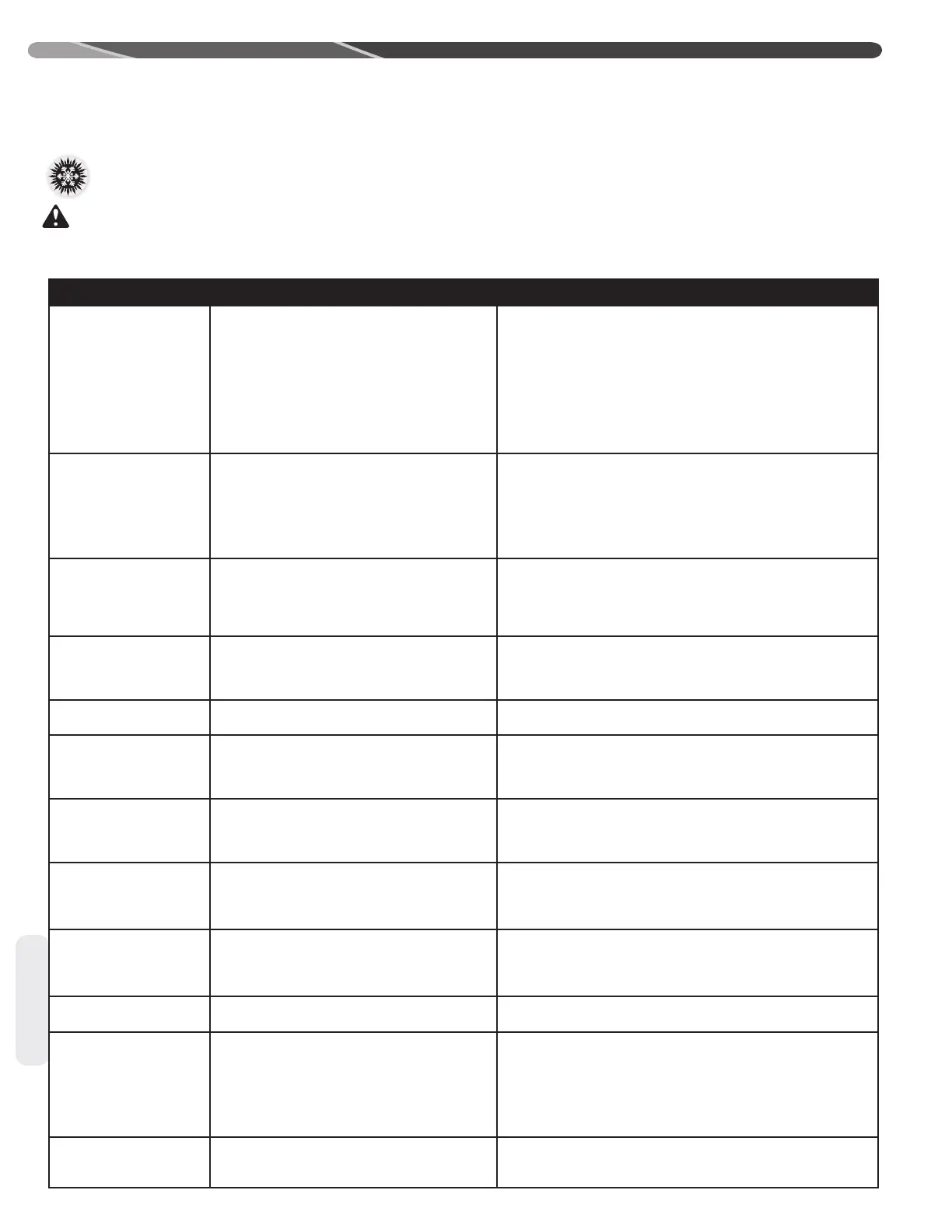

10.0 DIAGNOSTICS AND TROUBLESHOOTING

10.6 General Troubleshooting Guide

Diagnostics

WARNING: Disconnect all power to unit

before servicing. Contactor may break only one side. Failure

to shut off power can cause electrical shock resulting in per-

sonal injury or death.

SYMPTOM POSSIBLE CAUSE REMEDY

Unit will not run

• Power off or loose electrical connection

• Thermostat out of calibration - set too high

• Defective control board

• Blown fuses/tripped breaker

• Transformer defective

• High-pressure control lock-out

• Low-pressure control lock-out

• Miswiring of communications (communication

light on continuously)

• Check for correct voltage at line voltage connections in con-

densing unit.

• Reset

• Check control board diagnostic codes

• Replace fuses/reset breaker

• Check wiring. Replace transformer

• Reset by cycling power to unit. Also see high head and low

suction pressure remedies.

• Check for refrigerant leaks.

• Check communication wiring.

Outdoor fan runs,

compressor doesn’t

• Run or start capacitor defective

• Contactor defective

• Loose connection

• Compressor stuck, grounded or open motor

winding, open internal overload.

• Low-voltage condition

• Replace

• Replace

• Check for the correct voltage at compressor. Check and tighten

all connections.

• Wait at least 3 hours for overload to reset. If still open, replace

the compressor.

• Add start kit components.

Insufcient cooling

• Improperly sized unit

• Improper indoor airow

• Incorrect refrigerant charge

• Air, noncondensibles, or moisture in system

• Bad ID EXV or TXV

• Recalculate load

• Check. Should be approximately 400 CFM per ton

• Charge per procedure attached to unit service panel

• Recover refrigerant. Evacuate and recharge. Add lter drier

• Replace EXV or TXV

Compressor short cycle

• Incorrect voltage

• Defective overload protector

• Refrigerant undercharge or undercharge (HPC

or LPC cycling)

• At compressor terminals, voltage must be 10% of nameplate

marking when unit is operating.

• Replace. Check for correct voltage

• Add refrigerant

Registers sweat

• Low indoor airow • Increase speed of blower or reduce restriction.

• Replace air lter.

High head, low suction

pressure

• Restriction in liquid line, expansion device, or

lter drier

• Bad EXV or TXV

• Remove or replace defective component.

• Verify thermistor and pressure transducer connection and

operation

• Replace EXV or TXV

High head, high or normal

suction pressure - Cooling

mode

• Dirty outdoor coil

• Refrigerant overcharge

• Outdoor fan not running

• Air or noncondensibles in system

• Clean coil

• Correct system charge

• Repair or replace

• Recover refrigerant. Evacuate and recharge

Low head, high suction

pressure

• EXV in bypass mode or TXV Check valve

stuck open

• Bad compressor

• Verify thermistor and pressure transducer connection and

operation

• Replace EXV or TXV

• Replace compressor

Low suction, cool com-

pressor, iced indoor coil

• Low indoor airow

• Operating below 65oF outdoors

• Moisture in system

• Restricted indoor coil circuit

• Increase speed of blower or reduce restriction. Replace air lter

• Add Low Ambient Kit

• Recover refrigerant. Evacuate and recharge. Add lter drier

• Repair or replace indoor coil

High suction pressure

• Excessive load

• Defective compressor

• Recheck load calculation

• Replace

Fluctuating head and

suction pressure

• EXV or TXV hunting

• Air or noncondensibles in system

• Check thermistor to suction line connection

• Check air distribution on coil

• Check suction thermistor and pressure transducer and opera-

tion

• Recover refrigerant. Evacuate and recharge.

• Remove and conrm EXV movement. Clean EXV inside with

nitrogen to remove any debris then reinstall

Gurgle or pulsing noise

at expansion device or

liquid line

• Air or noncondensibles in system

• Undercharged System

• Recover refrigerant. Evacuate and recharge

• Adjust charge per charging chart

Loading...

Loading...