7

4.0 INSTALLATION

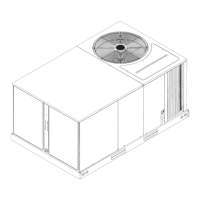

4.1 Tools and Refrigerant

4.1.1 Tools Required for

Installing and Servicing

R-410A Models

Tools

Manifold Sets:

– Up to 800 PSIG [5,516 kPa] High-Side

– Up to 250 PSIG [1,724 kPa] Low-Side

– 550 PSIG [3,792 kPa] Low-Side Retard

Manifold Hoses:

– Service Pressure Rating of 800 PSIG [5,516 kPa]

Recovery Cylinders:

– 400 PSIG [2,758 kPa] Pressure Rating

– Dept. of Transportation 4BA400 or BW400

Ambient and Tube

Thermometers

Crescent Wrench

Allen Wrench

Manifold

Gauge

Set

Brazing

Rods

Recovery

Cylinders

Torch

Reclaimer Nitrogen

CAUTION:

R-410A systems operate

at higher pressures than R-22 systems. DO NOT

use R-22 service equipment or components on

R-410A equipment.

Application: R-410A is not a drop-in

replacement for R-22 . Equipment designs must

accommodate its higher pressures. It cannot be

retrotted into R-22 equipment.

Physical Properties: R-410A has an atmospheric

boiling point of -62.9°F [-52.7°C] and its saturation

pressure at 77°F [25°C] is 224.5 psig [1,548 kPa].

Composition: R-410A is a near-azeotropic

mixture of 50% by weight diuoromethane (HFC-

32) and 50% by weight pentauoroethane (HFC-

125).

Pressure: The pressure of R-410A is

approximately 60% (1.6 times) greater than

R-22. Recovery and recycle equipment, pumps,

hoses, and the like must have design pressure

ratings appropriate for R-410A.

Manifold sets

need to range up to 800 psig [5,516 kPa] high-side

and 250 psig [1,724 kPa] low-side with a 550 [3,792

kPa] psig low-side retard Hoses need to have a

service pressure rating of 800 psig [5,516 kPa].

Recovery cylinders need to have a 400 [2,758 kPa]

psig service pressure rating, DOT 4BA400 or DOT

BW400.

Combustibility: At pressures above 1

atmosphere, a mixture of R-410A and air can

become combustible. R-410A and air should

never be mixed in tanks or supply lines or

be allowed to accumulate in storage tanks.

Leak checking should never be done with a

mixture of R-410A and air. Leak-checking can

be performed safely with nitrogen or a mixture of

R-410A and nitrogen.

4.1.3 Quick-Reference Guide

for R-410A

4.1.2 Specications of R-410A

• R-410A refrigerant operates at approximately 60%

higher pressure (1.6 times) than R-22. Ensure that

servicing equipment is designed to operate with

R-410A.

• R-410A refrigerant cylinders are light rose in color.

• R-410A, as with other HFCs, is only compatible with

POE oils.

• Vacuum pumps will not remove moisture from POE

oil used in R-410A systems.

• R-410A systems are to be charged with liquid

refrigerants. Prior to March 1999, R-410A

refrigerant cylinders had a dip tube. These

cylinders should be kept upright for equipment

charging. Post-March 1999 cylinders do not have

a dip tube and should be inverted to ensure liquid

charging of the equipment.

• DO NOT install a suction line filter drier in the liquid

line.

• A factory-approved liquid line filter drier is shipped

with every unit and must be installed in the liquid

line at the time of installation. Only manufacturer-

approved liquid line filter driers should be used.

Filter driers must have a working pressure rating

of at least 600 psig [4,137 kPa]. The filter drier will

only have adequate moisture-holding capacity if the

system is properly evacuated.

• Desiccant (drying agent) must be compatible for

POE oils and R-410A refrigerant.

Loading...

Loading...