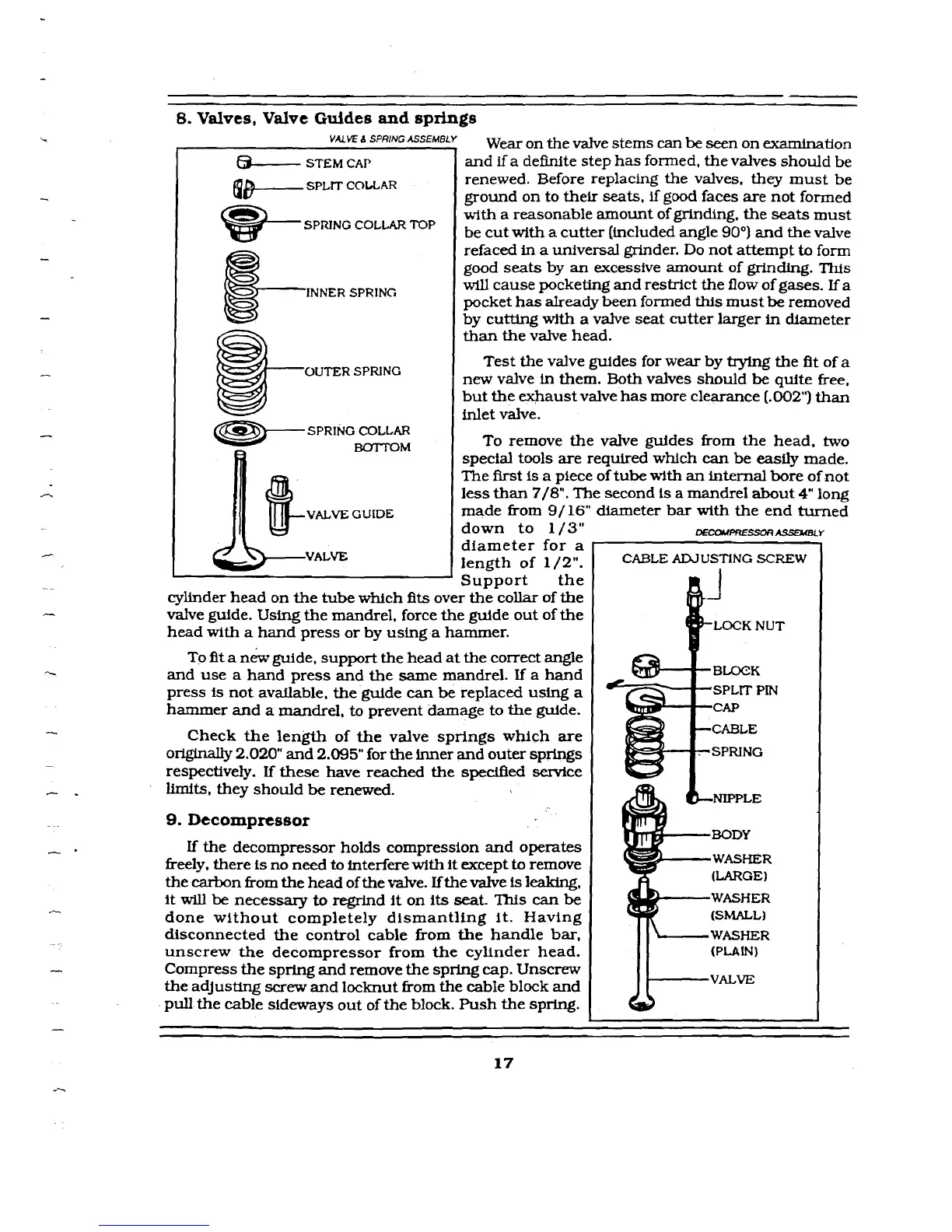

8.

Valves, Valve

Guides and springs

a

6-

STEM

CAP

spur

COLLAR

sPNNC

INNER SPRING

OUTER

SPRING

F

@B-

spRING~~

VALVE

GUIDE

Wear

on the vahe stems

can

be

seen on examination

and ifa de£inite step has formed, the valves should

be

renewed. Before replacing the valves,

they

must be

ground on to their

seats,

if

good

faces are not formed

with

a

reasonable amount of

grinding.

the

seats

must

be

cut with

a

cutter (included angle

90')

and the valve

refaced

in

a

universal grinder. Do not attempt

to

form

good

seats by an excessive amount of

grinding.

This

will

cause pocketing and restrict the flow of

gases.

If

a

pocket has

already

been

formed this must

be

removed

by

cuttlng with

a

v&e seat cutter larger

in

diameter

than the

vahre head.

Test the valve guides for

wear

by

trying

the fit of

a

new valve

in

them. Both valves shuld

be

quite

free.

but the exhaust valve has more clearance

(.002")

than

Met valve.

To remove the valve guides

fYom the head. two

special tools are required which

can

be

easily

made.

The

ht is a piece of tube with

an

internal

bore of not

less than

7/8".

The second is

a

mandrel about

4"

long

made

fYom

9/

16"

diameter bar

with

the end turned

down to

1/3"

~SSOR~Y

diameter for a

VALVE

L!

length Support of

1/2".

the

CABLE

ADJ

USTINC

SCREW

cylinder head on the

tube

which

fits

over the collar of the

valve guide. Using the mandrel. force the guide out of the

head with a hand press or by using a hammer.

To

fit

a new guide, support the head at the correct angle

and use a hand press and the same mandrel.

If

a hand

press

is

not available, the guide

can

be

replaced using

a

hammer and

a

mandrel,

to

prevent damage to the guide.

Check the length of

the

valve springs which are

oiighml&

2.020

and

2.095

for the inner and outer springs

respectively.

If

these have reached the specified sewice

limits,

they should

be

renewed.

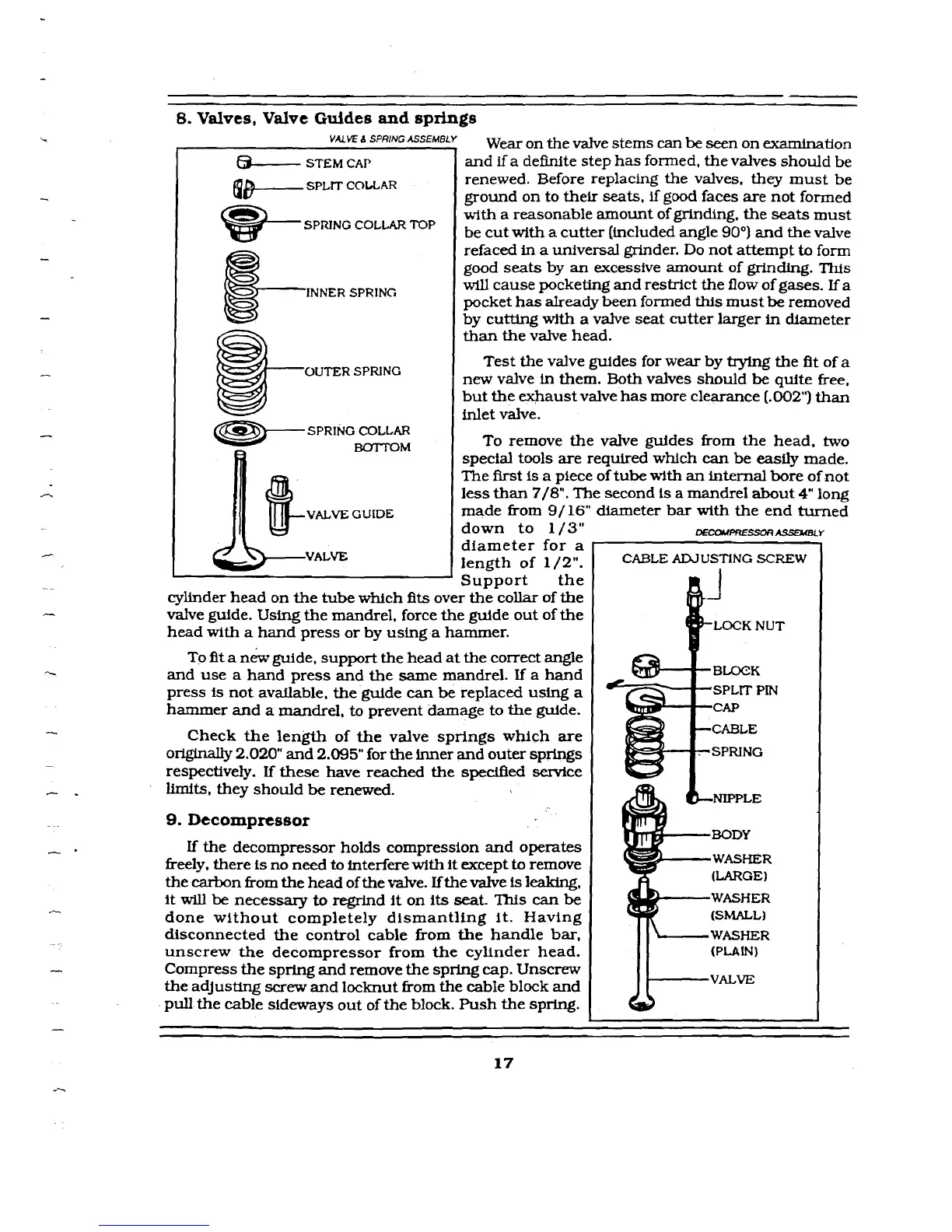

9.

Decompressor

If

the decompressor holds compression and

operates

freely.

there is no need

to

interfere with it except

to

remove

the carbon

fYom the head of the vdve.

If

the valve

is

leaking.

it

will

be

necessary

to

regrind it on its

seat

This

can

be

done without completely dismantling it. Having

disconnected the control cable from

the

handle bar.

unscrew the decompressor from the cylinder head.

Compress the spring and remove the spring cap. Unscrew

the adjusting

screw

and locknut f?om the cable block and

pull the cable sideways out of the block. Push the spring.

Loading...

Loading...