28

Performing leak test & insulation

Once you have checked that there are no leaks in the system, you can insulate the piping and hose.

1

To avoid condensation problems, place T13.0 or thicker Acrylonitrile Butadien Rubber separately around each refrigerant

pipe.

2 Wind insulating tape around the pipes and drain hose avoiding to compress

the insulation too much.

3

Finish wrapping insulating tape around the rest of the pipes leading to the outdoor

unit.

4 The pipes and electrical cables connecting the indoor unit with the outdoor

unit must be xed to the wall with suitable ducts.

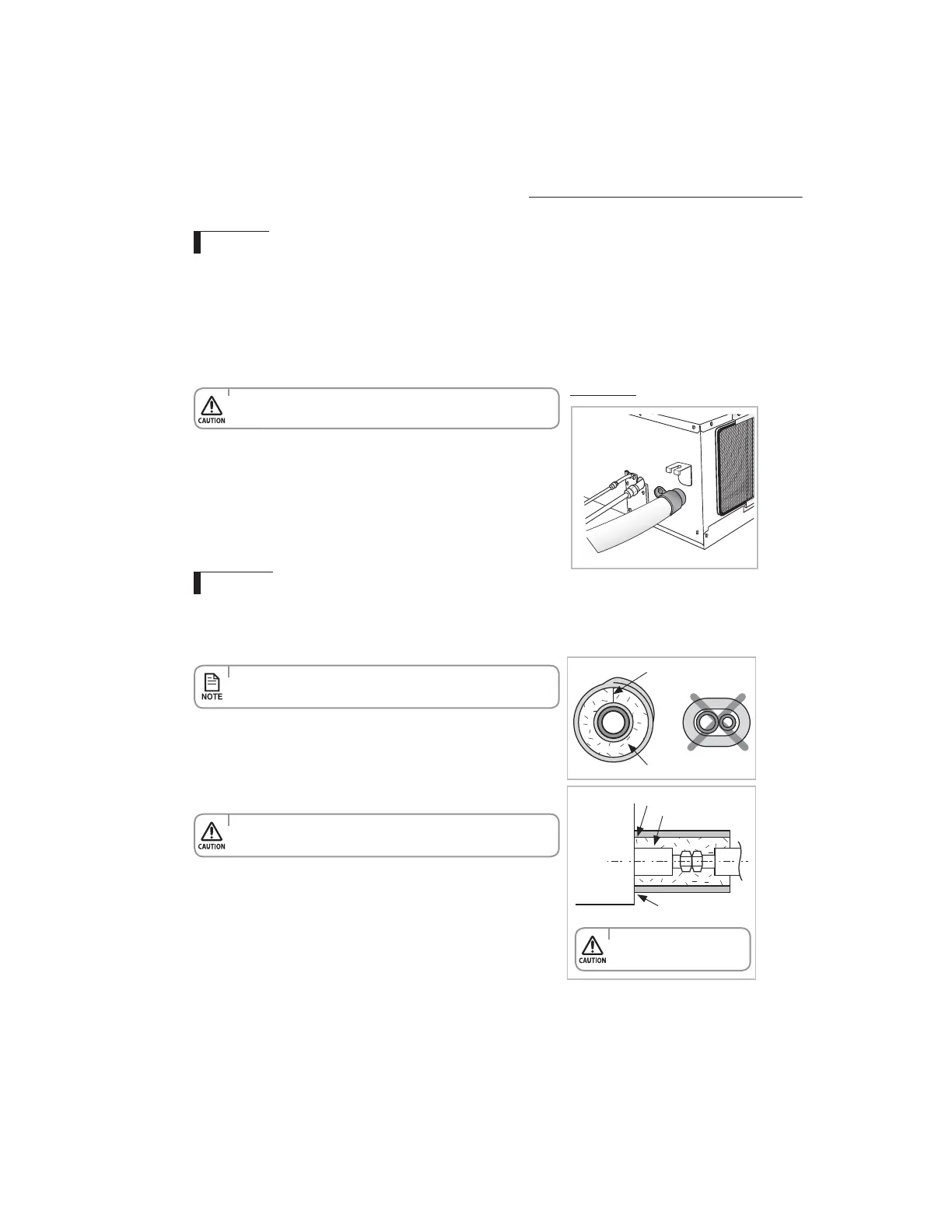

5 Select the insulation of the refrigerant pipe.

◆ Insulate the gas side and liquid side pipe referring to the thickness

according to the pipe size.

◆

*OEPPSUFNQFSBUVSFPG¡'¡$BOEIVNJEJUZPGJTUIFTUBOEBSEDPOEJUJPO

If installing in a high humidity condition, use one grade thicker insulator by

referring to the table below.

If installing in an unfavorable conditions, use thicker one.

◆ Insulator’s heat-resistance temperature should be more than 248

¡'

¡$

Leak test

Insulation

No gap

/#3<5JODINNPSUIJDLFS>

Insulation cover pipe

Indoor unit

Be sure to overlap

the insulation

Insulation pipe

t .VTUöUUJHIUMZBHBJOTU

body without any gap.

t "MXBZTNBLFUIFTFBNPGQJQFTGBDFVQXBSET

t "MMSFGSJHFSBOUDPOOFDUJPONVTUCFBDDFTTJCMFJOPSEFSUPQFSNJU

either unit maintenance or removing it completely.

◆

LEAK TEST WITH NITROGEN (before opening valves)

In order to detect basic refrigerant leaks, before recreating the vacuum and recirculating the R-410A, it’s responsable

of installer to pressurize the whole system with nitrogen (using a cylinder with pressure reducer)

at a pressure above 30 bar (gauge).

◆

LEAK TEST WITH R-410A (after opening valves)

Before opening valves, discharge all the nitrogen into the system and create vacuum. After opening valves check

leaks using a leak detector for refrigerant R-410A.

MA Duct Type

t %JTDIBSHFBMMUIFOJUSPHFOUPDSFBUFBWBDVVNBOEDIBSHFUIFTZTUFN

Loading...

Loading...