Design

D - 9

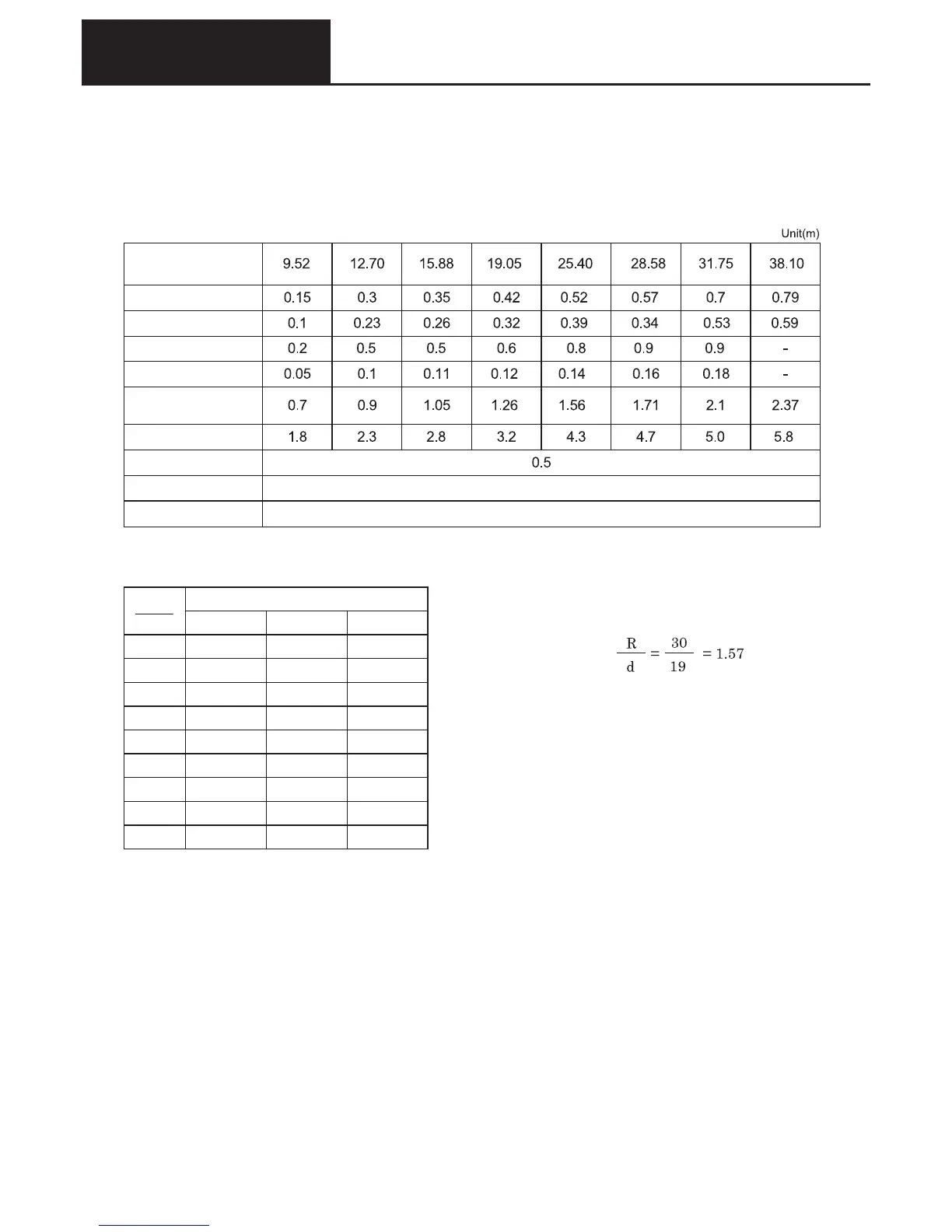

3. Refrigerant piping design

Intake pipe or thick

pipe (gas pipe)

90°elbow

45°elbow

Tees

Socket

U bend

(R60~100mm)

Trap bend

Branch pipe

Header pipe 1

Ball valve for service Not necessary to calculate an effective length

φφφφφφφφ

Effective length

R

d

45°bend 90°bend 180°bend

0.5 25.0×d 40.0×d

53.5×d

1.0 12.0×d 18.5×d

25.8×d

1.5 7.8×d 12.2×d 16.4×d

2.0 6.4×d 10.0×d 13.4×d

2.5 5.9×d 9.2×d 12.3×d

3.0 5.7×d 9.0×d 12.0×d

3.5 5.9×d 9.2×d 12.2×d

4.0 6.4×d 10.0×d 13.4×d

4.5 7.1×d 11.0×d 14.8×d

(4) Effective length of refrigerant piping

The effective straight length of the connectors used in the piping system is given in the table below. The piping system

design should be based upon this.

● Effective straight length of connectors (Table 3)

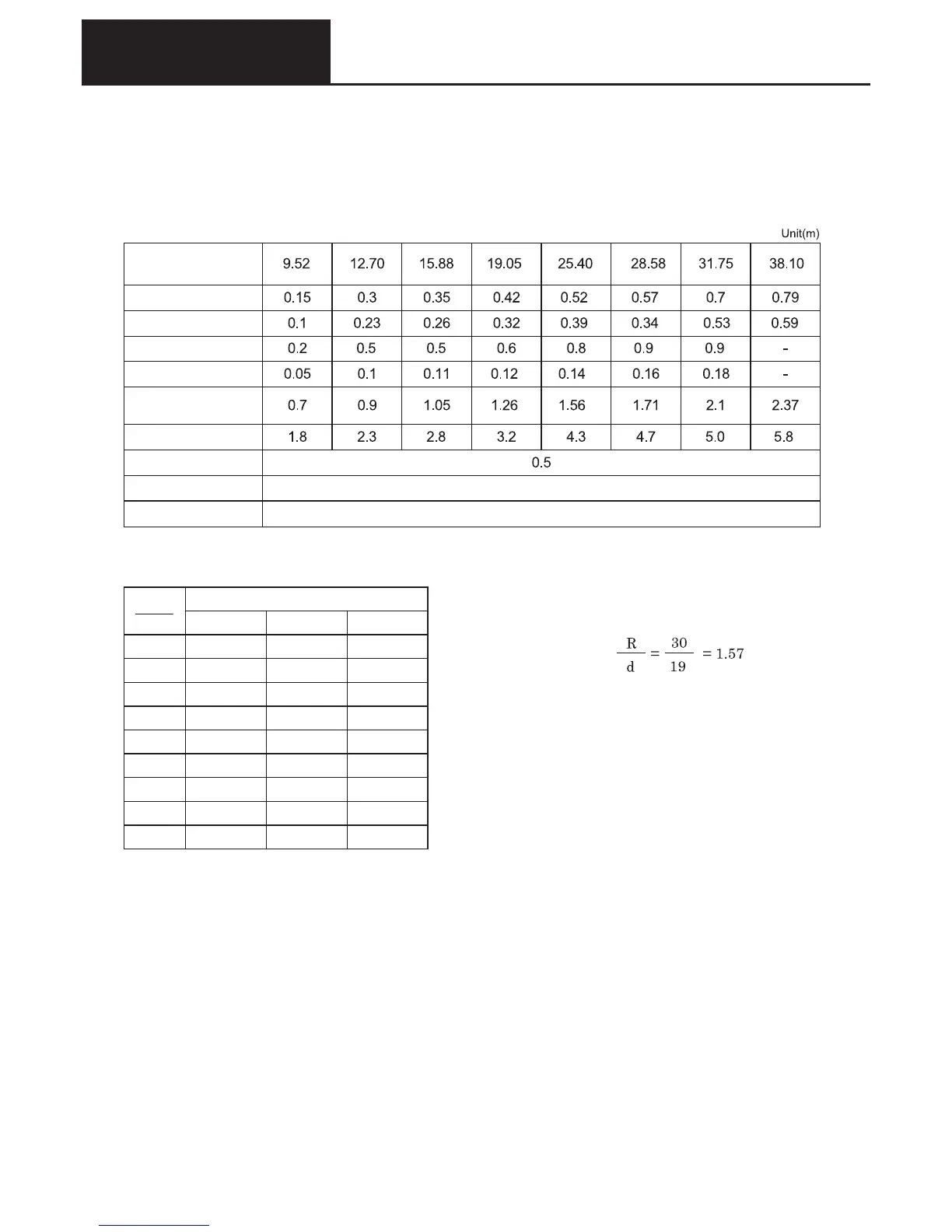

● Effective straight length of bent pipe (Table 4)

Calculation example

d: Outer diameter

R: Bend radius

(Example)

For a 19mm pipe bent through 90

o

on a 30mm radius (d=19, R=30)

from the table

length = 12.2 x 19 = 231mm

0.23 is the result.

Loading...

Loading...