Construction

E - 5

1. Points regarding refrigerant piping construction

(3) Refrigerant piping connection operations

1Refrigerant piping materials

Piping should be “phosphorous de-oxidized copper seamless tube (C1220T).” Piping size shall be in accordance

with the following table.

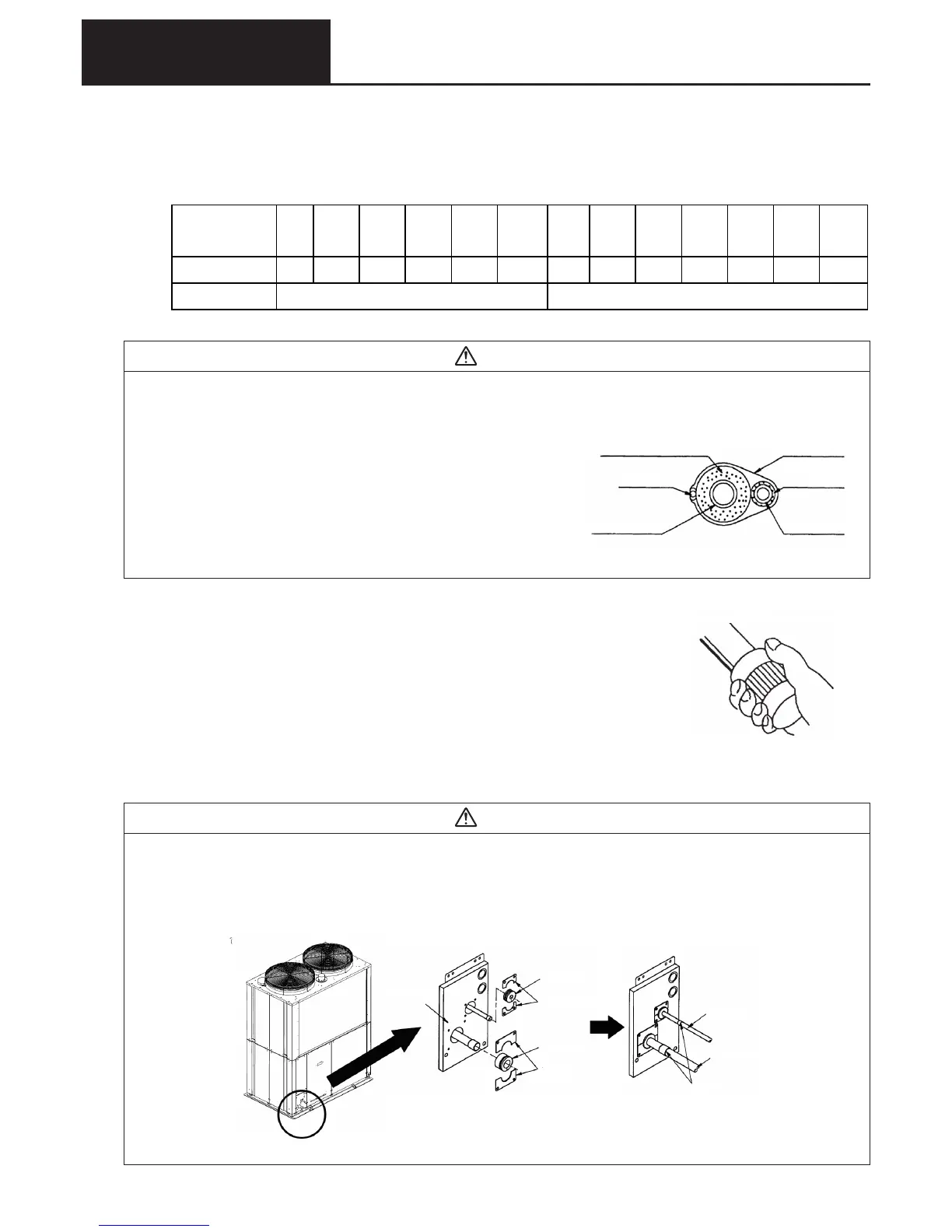

● All the unit piping, including the branch must be insulated. The gas side system (thick pipe) must be

insulated to greater than 120

o

C, and the liquid side (thin pipe) to greater than 80

o

C. (See Figure 1.)

For external diameters of 38.1mm or more the thickness should be

15mm, and for other sizes it should be 10mm.

If the conditions within the ceiling can exceed DB30

o

C or RH70%

then this thickness should be increased.

Improper insulationg can be the cause of water leaks and

condensation.

Use separate conduit for the electricity cables and the operation

cables. If the same conduit is used, a malfunction may result from

the effects of noise and induction.

Caution

Nominal external

diameter

φ6.35 φ9.52 φ12.7 φ15.88 φ19.05 φ22.2 φ25.4 φ28.58 φ31.75 φ38.1 φ41.28 φ44.45 φ50.8

Thickness T0.8 T0.8 T0.8 T1.0 T1.0 T1.15 T1.0 T1.0 T1.1 T1.15 T1.2 T1.25 T1.4

Specification

O material

1/2H or H material

2Cautions regarding construction

3 Select the gas pipe (thick pipe), liquid pipe (thin pipe), branches (separately sold) and make necessary

preparations for installation.

●After cutting the pipe, remove all burrs, and correctly finish the ends.

(similarly for separately sold branch fittings)

●During cutting and bending operations do not damage the pipe.

●Make sure that no water or sand can enter the pipe.

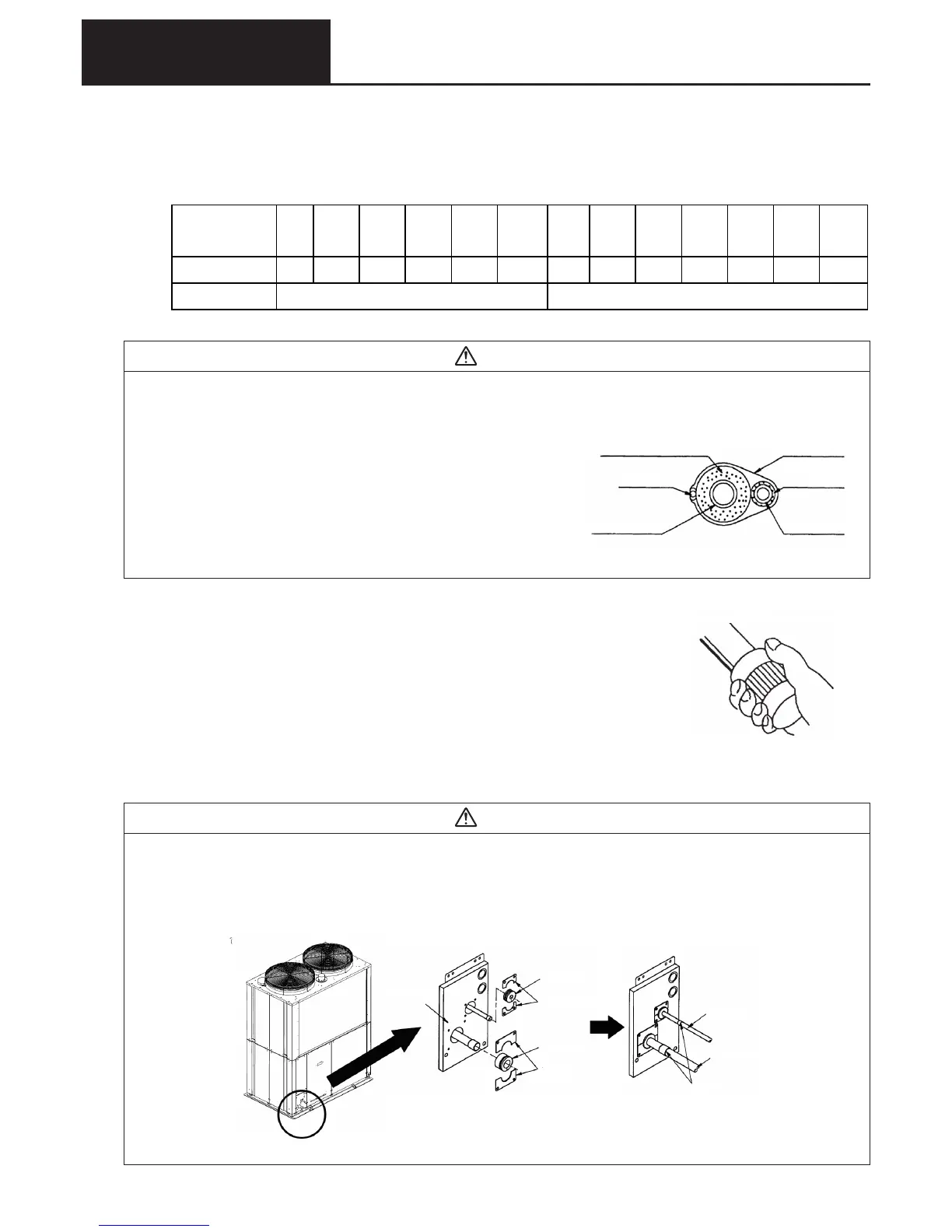

4 Connecting pipes

●Carry out as follows.

1) Remove the fixing rubber by removing the gas pipe and the liquid pipe fixing

panel from the piping connection panel (See Fig. 3.).

2) Connect the piping, and braze.

3) Return the fixing rubber to the gas pipe and the liquid pipe. (Fig. 4)

Caution

Before brazing operations, complete the following.

● The rubber for fixing the pipe is not resistant to heat, so before brazing be sure to remove it.

● During brazing, cool the piping with wet cloth, etc. so that the heat does not cause damage to the valve

inside of the equipment.

● Commercial anti-oxidants have adverse reactions on refrigerants and the refrigeration oil, so they should not

be used

Piping

connection

panel

Liquid pipe

fixing panel

Gas pipe

fixing rubber

Gas pipe

fixing panel

Liquid pipe

fixing rubber

Liquid pipe

(thin pipe)

Gas pipe

(thick pipe)

Brazing

Fig. 1

Fig. 2

Fig. 3 Fig. 4

Loading...

Loading...