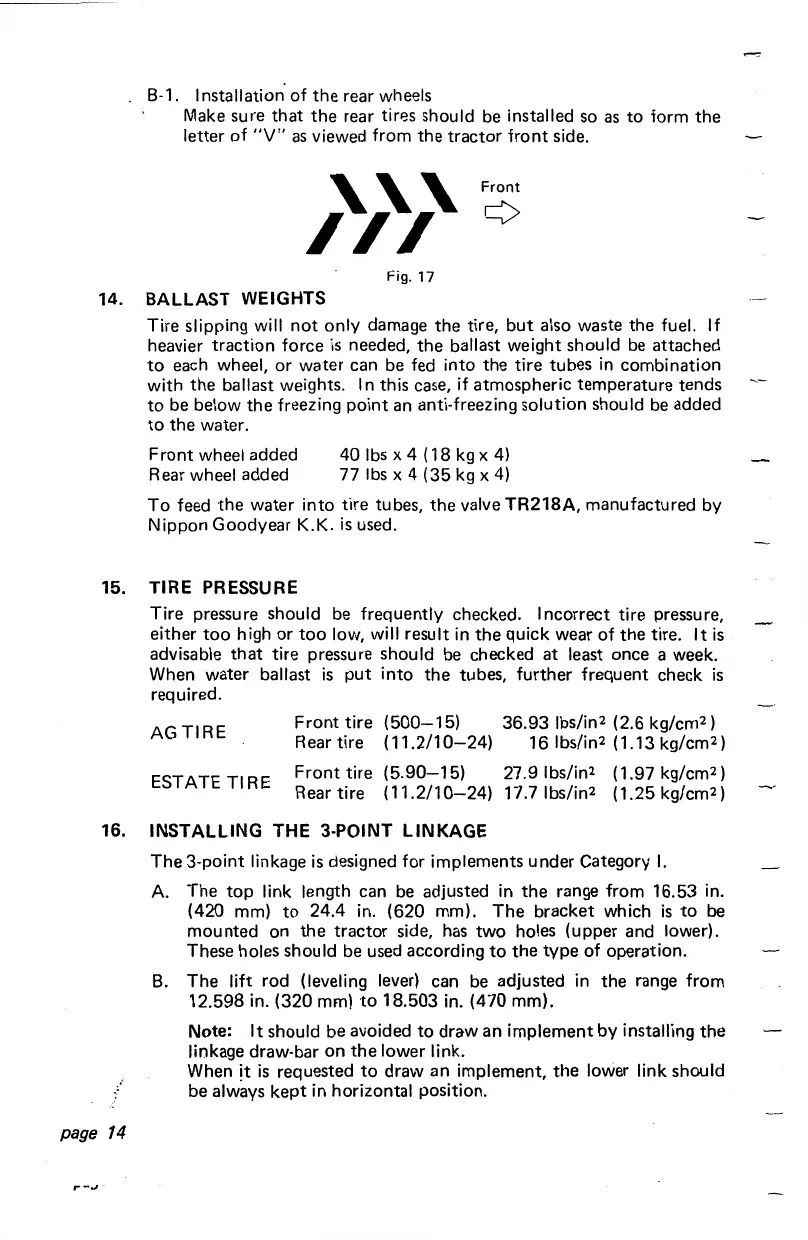

B-1.

Installation of

the

rear wheels

Make sure

that

the

rear

tirr:ls

should be installed so

as

to

form

the

letter

of

"V"

as

viewed from

the

tractor

front

side.

Front

Fig.

17

14. BALLAST WEIGHTS

Tire slipping will

not

only damage

the

tire,

but

also waste the fuel.

If

heavier traction force

is

needed,

the

ballast weight should be attached

to

each wheel, or water can be fed into the tire tubes

in

combination

with

the

ballast weights.

In

this case,

if

atmospheric temperature tends

to

be below

the

freezing point an anti-freezing solution should be added

to

the

water.

Front wheel added

Rear wheel added

40

lbs

X 4 (

18

kg

X

4)

77 lbs X 4 (35 kg X

4)

To

feed

the

water into tire tubes,

the

valve TR218A, manufactured by

Nippon Goodyear K.K.

is

used.

15.

TIRE

PRESSURE

Tire pressure should be frequently checked. Incorrect tire pressure,

either

too

high or

too

low, will result in

the

quick wear of

the

tire.

It

is

advisable

that

tire pressure should

be

checked

at

least once a week.

When water ballast

is

put

into

the

tubes, further frequent check

is

required.

AG

TIRE

ESTATE TIRE

Front

tire

(500-15)

Rear tire ( 11.2/1

0-24)

Front

tire

(5.90-15)

Rear tire

(11.2/10-24)

36.93

lbs/in2 (2.6 kg/cm2)

16 lbs/in2 ( 1.13 kg/cm2)

27.91bs/in2 (1.97 kg/cm2)

17.7 lbs/in2 (1.25 kg/cm2)

16. INSTALLING THE 3-POINT LINKAGE

page

14

The

3-point linkage

is

designed for implements under Category

I.

A.

The

top

link length can be adjusted in

the

range from 16.53 in.

(420 mm)

to

24.4 in. (620 mm).

The

bracket which

is

to

be

mounted on

the

tractor side, has two holes (upper and lower).

These holes should be used according

to

the

type

of operation.

B.

The

lift rod (leveling lever) can be adjusted in

the

range from

12.598 in. (320 mm)

to

18.503 in. (470 mm).

Note: It should be avoided

to

draw

an

implement

by

installing

the

linkage draw-bar on

the

lower link.

When it

is

requested

to

draw

an

implement,

the

lower link should

be always

kept

in horizontal position.

Loading...

Loading...