www.scheppach.com

GB

|

35

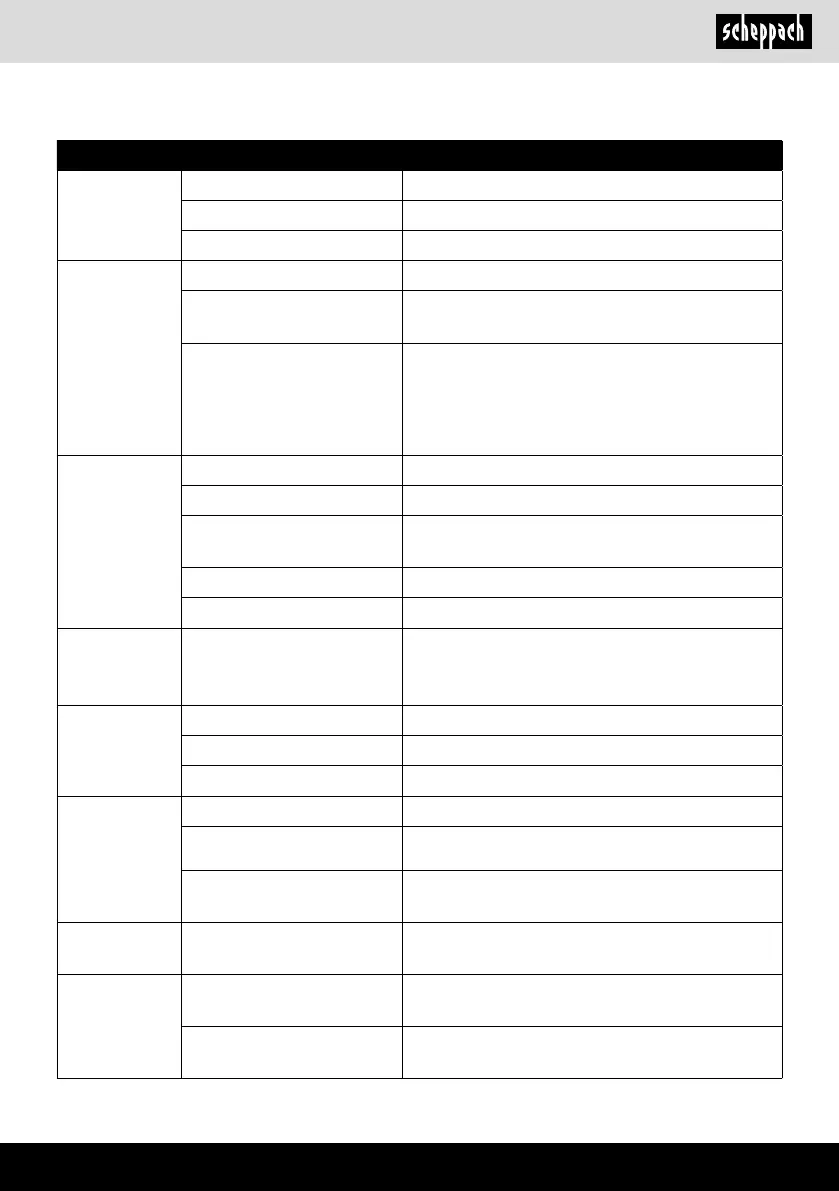

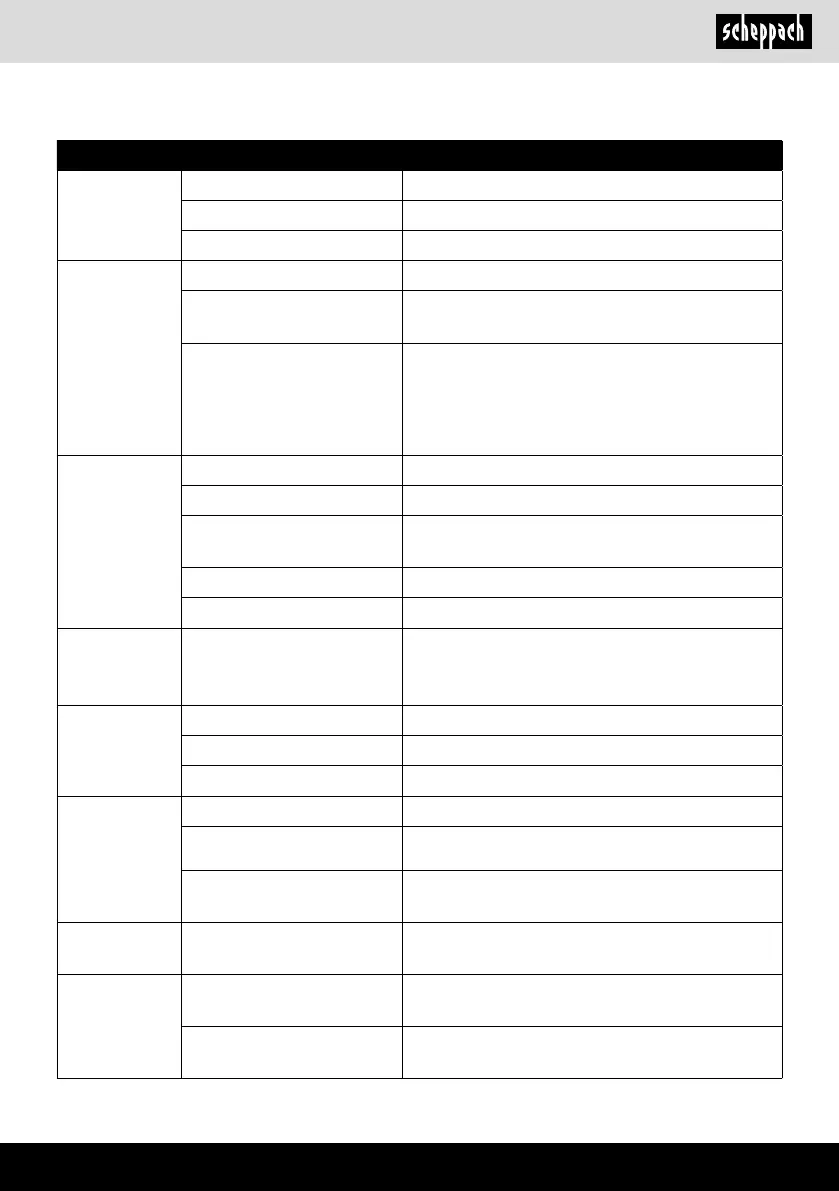

15. Troubleshooting

Fault Possible cause Remedy

The machine will

not switch on

Mains voltage is not available. Check power supply

Carbon brushes worn Contact the customer service workshop

Chip extraction not mounted Mount chip extraction

Machine without

any function or it

suddenly stops

Power failure Check fuse / overload protection

Motor or switch faulty

Have the motor or switch checked by a qualied electri-

cian.

Check micro switch

Mount the chip extractor in such a way that the micro

switch is started. Check fuse on the mains side. Due to

the built-in undervoltage protection, the machine does not

restart by itself and must be switched on again when the

voltage is restored.

Machine stops

when planing

Planing blade is blunt/worn Change or sharpen blade

Overload switch has triggered Switch back on engine after cool-down time

Check micro switch

Mount the chip suction hood or table locking mechanism

in such a way that the micro switch is started.

High degree of chip take-o Reduce chip take-o

Feed to high Reduce the feed speed

Workpiece

jammes when

planing thick-

nesser

Cutting depth to deep

Reduce cutting depth and process workpiece in several

working steps

Speed reduces

when planing

High degree of chip take-o Reduce chip take-o

Feed to high Reduce the feed speed

Blades are blunt Change blades

Unsatised

surface result

Planing blade is blunt/worn Change or sharpen blade

Planing blade has too many

chips

Remove chips

Uneven feed

Feed the workpiece with constant pressure and reduced

feed speed

Processed sur-

face too rough

Workpiece is too wet Use a dry workpiece

Processed sur-

face cracked

Workpiece has been processed

against the direction of growth

Process the workpiece from the opposite direction

Too much material planed o

at once

Process the workpiece in several operations

Loading...

Loading...