28 english

Maintenance

Always switch off the motor and disconnect the plug from

the power supply prior to any maintenance and cleaning

work.

The following maintenance points should be checked on the

scheppach ts 4020 circular saw blench.

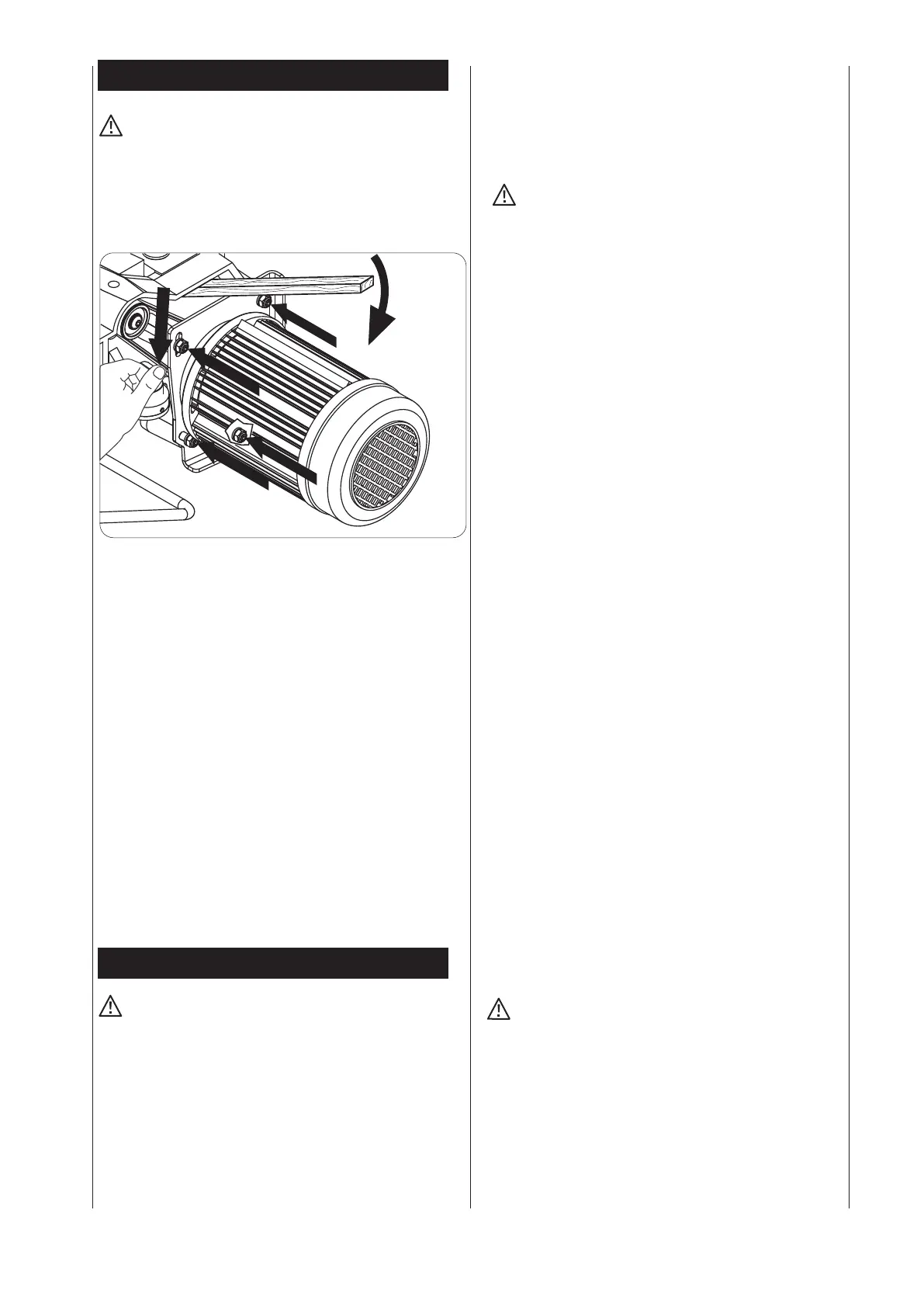

• Checkthe belt tensionafterapproximatelyoneoperating

hour; retension if necessary.

For this purpose Open the upper side wall. By uniform

adjustmentofthefasteningnutsonthemotor,adjustthe

necessarybelttension.Afterthisrstinitialadjustment,

check the belt tension at regular intervals.

• Occasionally,oilthe roller chainandmovingparts(height

andangleadjustment).

•Ensurethatthebench surface is always free of resin.

•Ifthecircularsawbenchisnotconnectedtoanextractor,

then it will be necessary to remove the saw dust and wood

chips that accumulate in the protective blade box. This is

important to ensure trouble- free ejection of the saw dust.

Remove the left blade-slot insert. If suction System is not

connectedwhenworking,theheightandangleadjustment

range may be restricted due to chip accumulation.

All protection and safety devices must be replaced after

completing repair and maintenance procedures.

•Thesawprotectionboxmustbeclearedoccasionallyof

wood shavings and saw dust so that shavings do not jam

when ejected.

•heheightandangularadjustmentareamaybereducedby

shaving deposits. Remove the left bench inlay and clean the

adjustment area.

Electrical connection

The installed electric motor is com- pletely wired ready

for operation.

Yhe customer‘s connection to the power supply system, and any

extension cables that may be used, must conform with local

regulations.

Motor braking unit

The scheppach machine is fitted with an automatic motor

braking unit which becomes effective as soon as the driving

motor is switched off.

Thesawblademuststopmaximal10secondsafterswitching

itoff.Poofdaily!

Ifittakeslonger,donotusethemachineanymore.

lmportant information

The 230 V / 50 Hz and 400 V / 50 Hz electric motor is designed

for the S6 / 40% operating mode.

The motor automatically switches off if it is overloaded. The

motor can be switched on again after a cooling- down period

(varies timewise).

Faulty electrical connecting leads

lnsulation damage often occurs at elec- trical connecting

leads.

Causes include:

•Pressuremarkscausedwhenconnectingleadsarerun

through windows or the cracks of doors.

•Foldscausedbytheimproperattachmentofrunningof

the connecting leads.

•Cutsresultingfromthecrossingoftheconnectinglead.

•lnsulationdamagescausedbytherippingoutofthe

connecting lead from the wall socket.

•Cracksduetotheageingoftheinsulation.

Faulty electrical connecting leads such as these may not be used

and are highly dangerous due to the insu- lation damage.

Check electrical connecting leads regu larly for damage.

Ensurethattheconnectingleadisnotattachedtothemains

supply when you are checking it.

Electricalconnectingleadsmustcorrespondtotherelevant

VDEandDINregulations.Onlyuseconnectingleadswith

thecodeH07RN.

The type designation must be printed on the connecting lead

by regulation.

Single-phase motor

• The supply voltage must be 230 volt - 50 Hz.

•Extensionleadsupto25minlengthmusthavea

crosssectionof1.5mm2.Extensionleadswhoselengthis

over 25 m must have a cross-section of at least 2.5 mm2

•Themainsconnectionisfusedwitha16Aslowblowfuse.

Three-phase motor

The 400 V / 50 Hz electric motor is designed for the S6 / 40%

operating mode.

•Thesupplyvoltagemustbe400volt50Hz.

•Themainsconnectionandtheextensionleadmusthave

5wires=3P+N+PE.

•Theextensioncablesmusthaveaminimumcrosssection

of 1.5 mm2

•Themainsconnectionismaximallyfusedwitha16Afuse.

•Thephasesequencemustbecheckedifthemains

connection or the location is changed. The polarity must

bechanged,ifnecessay(wallsocket)

Connections or repairs on the electrical equipment may only

be carried out by an electrician.

Please give the following information if you have any enquiries.

•Motormanufacturer

•Kindofcurrent

•Machinetypelabeldata

If your are sending back the motor, always send the complete

drive unit with the switch.

2-3mm

Loading...

Loading...