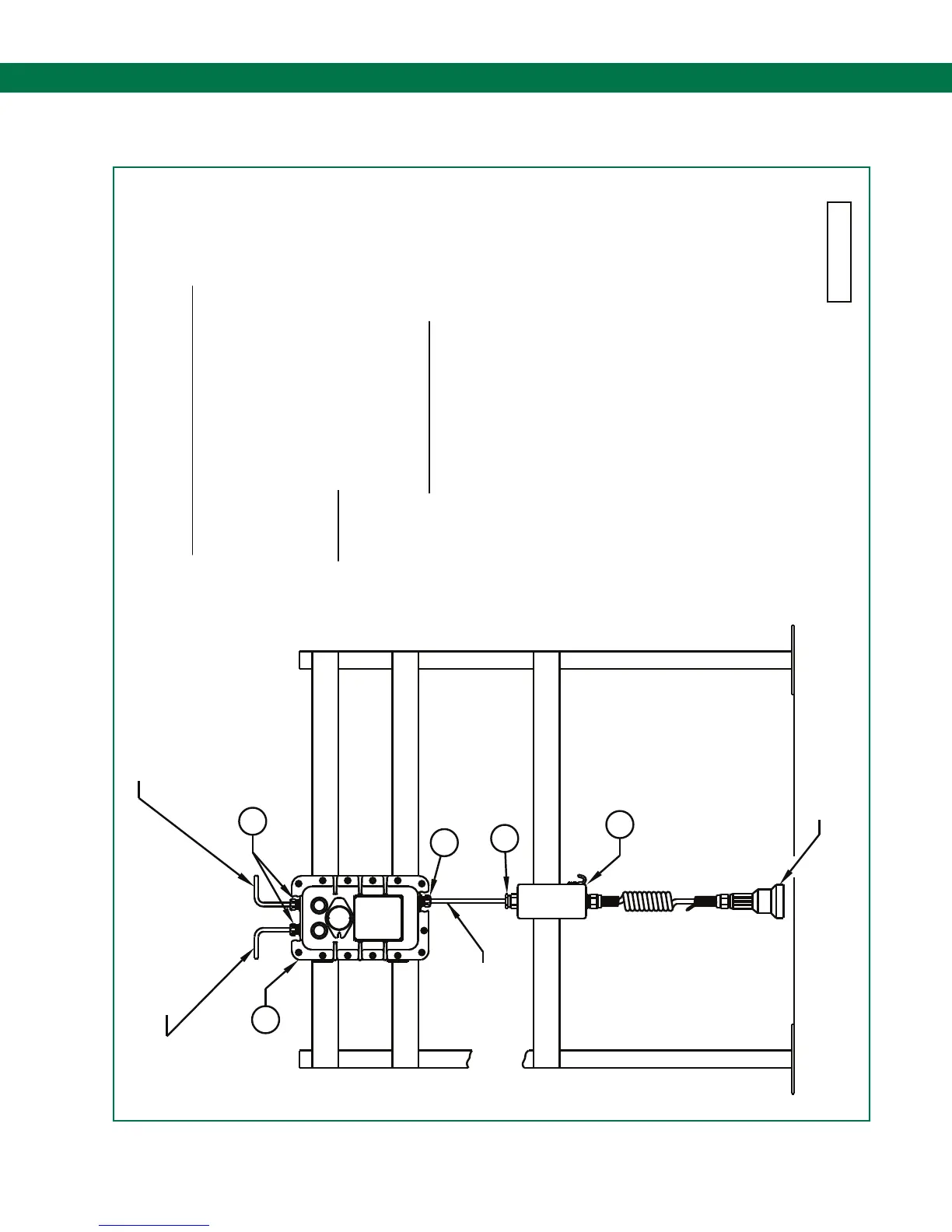

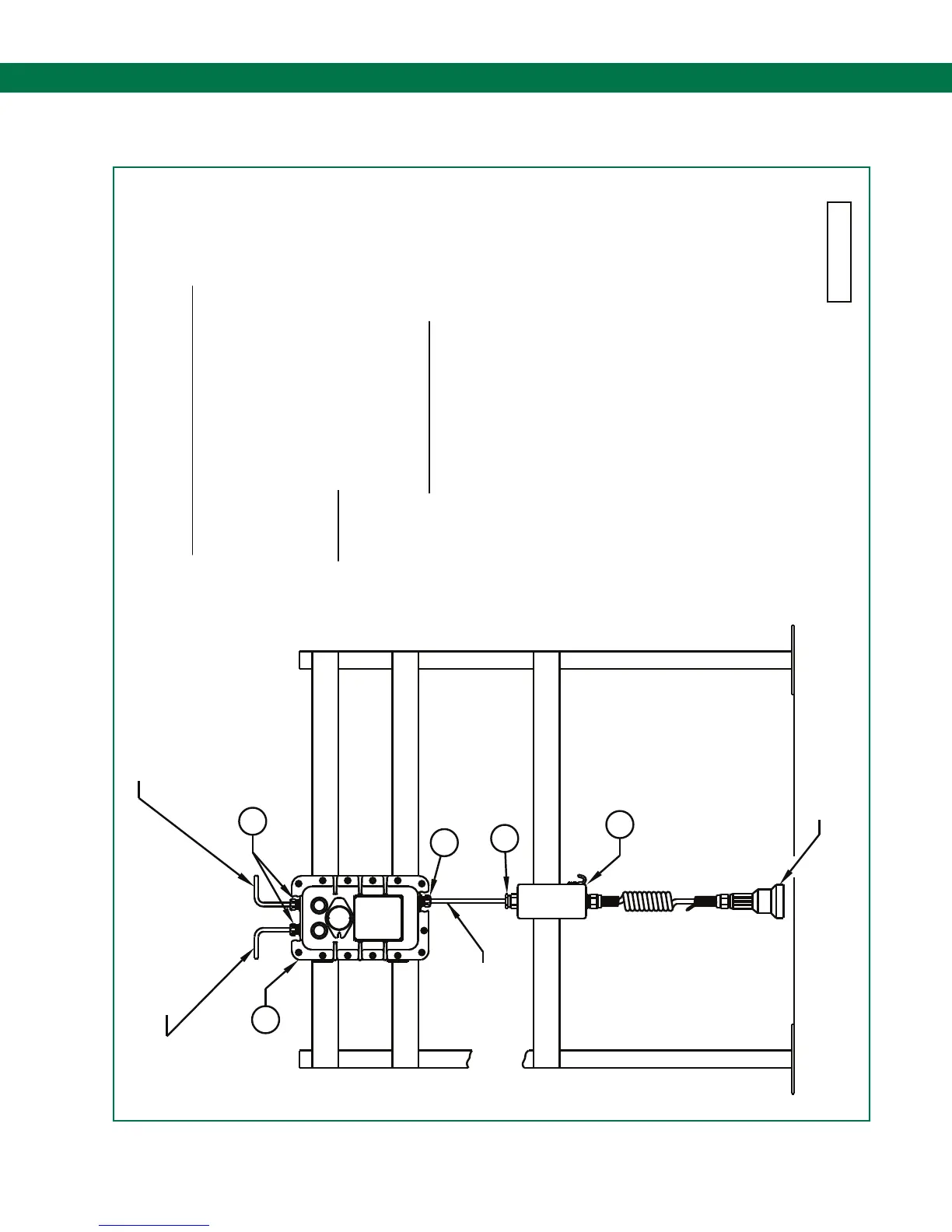

Self-Proving Vehicle Grounding Verication System

Diagram Appendix

Page 23.

61442 RevC

WIRING USING SEPARATE

INTRINSICALLY SAFE

CABLE

PLUGGED USING A CERTIFIED FLAMEPROOF STOPPER PLUG.

IN THIS CABLE OR CONDUIT.

AND THE CONTROL UNIT ENCLOSURE AT ALL CABLE PORT ENTRIES.

4. USE FIBER SEALING WASHERS BETWEEN THE CABLE GLAND FITTINGS

THE CONTROL UNIT ENCLOSURE TO AVOID CONDENSATION CHANNELING.

OR IN A CONDUIT. NO OTHER SIGNALS ARE TO BE RUN

JUNCTION BOX MUST BE RUN USING DEDICATED CABLE

OF THE CONTROL UNIT ENCLOSURE AND THE SCULCON

2. THE INTRINSICALLY SAFE WIRING BETWEEN THE BOTTOM PORT

INTENDED TO REPRESENT CODE COMPLIANCE.

DETAILS SHOWN ARE FOR REFERENCE ONLY AND ARE NOT

REGULATIONS FOR INSTALLATIONS IN HAZARDOUS LOCATIONS

3. MINIMIZE LONG VERTICAL RUNS OF CABLE INTO THE TOP PORTS OF

INSTALLATION NOTES

1. INSTALLATION MUST COMPLY WITH NATIONAL AND LOCAL

5. ANY UNUSED HOLES IN THE FLAMEPROOF ENCLOSURE MUST BE

OVERFILL PREVENTION SYSTEM ON

PLUG ASSEMBLY TO CONNECT TO

VEHICLE.

2

4

3

4. INDUSTRIAL CABLE GLAND FITTING.

2. SCULCON JUNCTION BOX WITH PLUG AND CABLE.

1. CONTROL UNIT

EQUIPMENT SCHEDULE (TYPICAL)

3. FLAMEPROOF Exd CABLE GLAND FITTING.

(PLUG HOLE IF NOT USED)

ALTERNATIVE ENTRY FOR

OUTPUT CONTROL WIRING

MAINS POWER AND OUTPUT

CONTROL WIRING

1

3

EACH CONDUIT (NOT SHOWN).

EXPLOSION-PROOF ENCLOSURE IN A HAZARDOUS LOCATION, IN

IMPORTANT: INTRINSICALLY SAFE AND NON-INTRINSICALLY SAFE

MUST BE INSTALLED WITHIN 18 INCHES OF AN

WIRING MUST ALWAYS BE SEPARATED AND

RUN IN SEPARATE CONDUITS/CABLES.

IF CONDUITS ARE USED FOR CABLE ENTRY, SEAL FITTINGS

6.7 DWG 61442 – Mounting Diagram – Control Unit & Junction Box

Loading...

Loading...