7. FAULT AND WARNING CODES English

© Siemens plc 1999 G85139-H1751-U529-D1

63

4/8/9

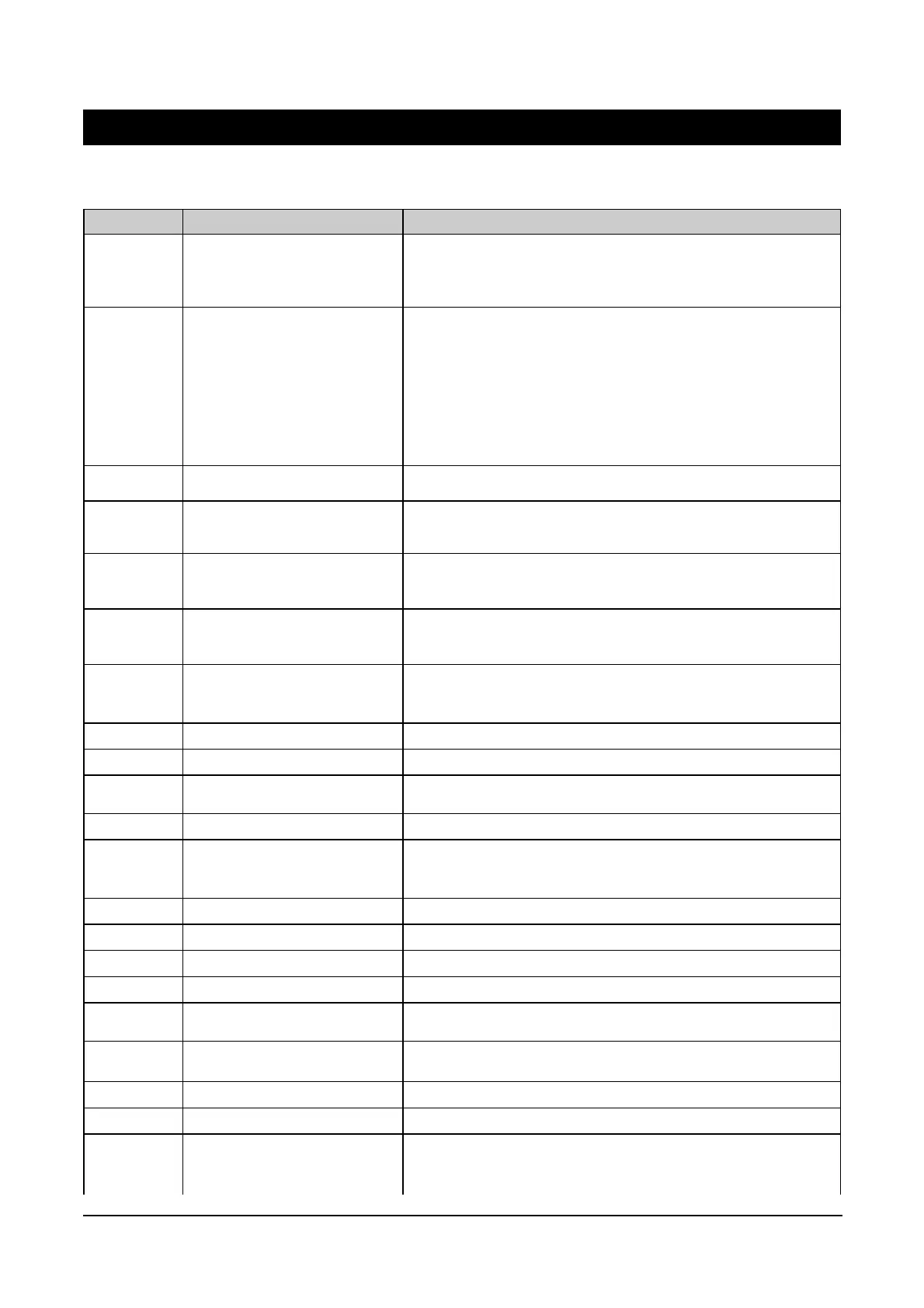

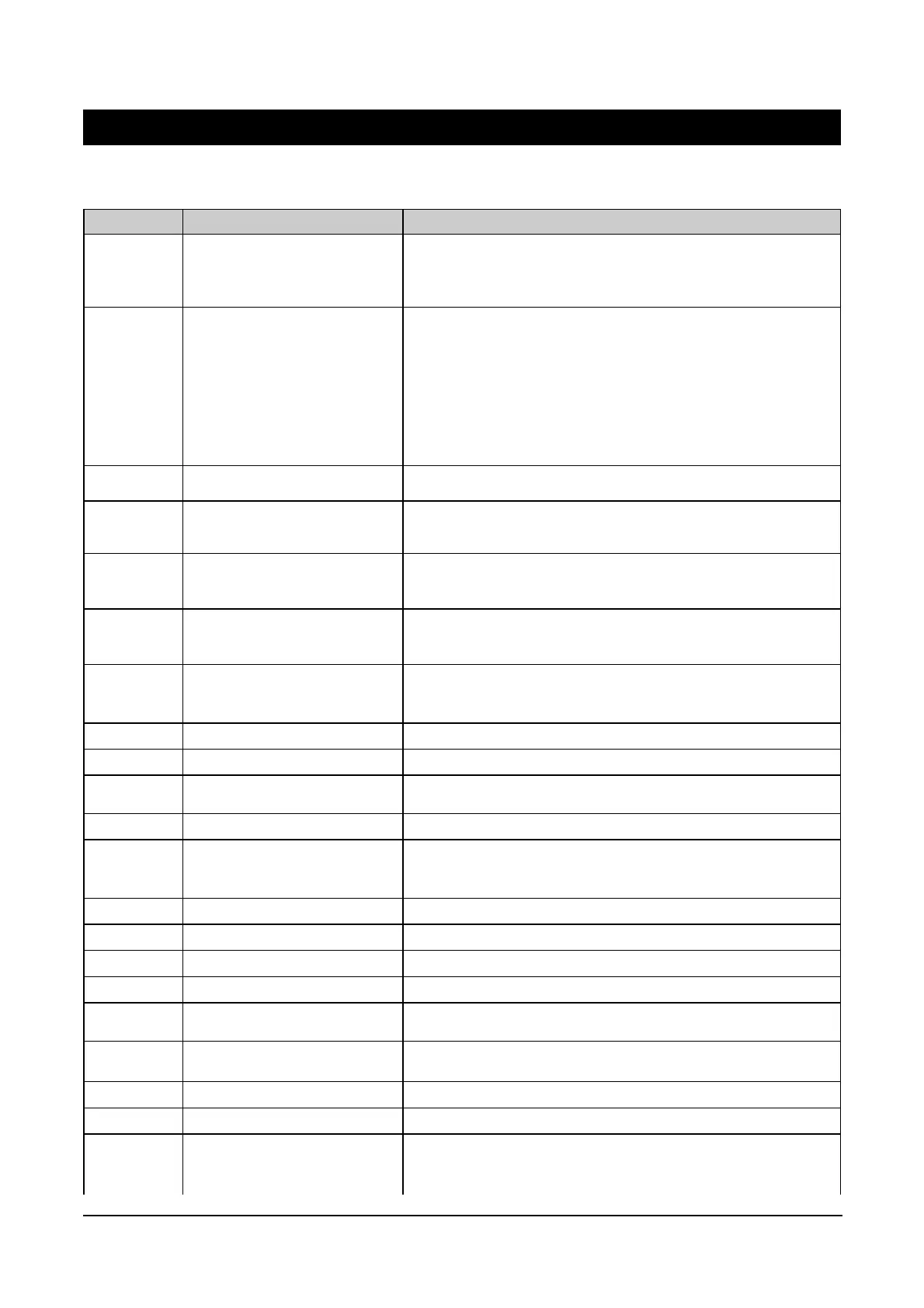

7. FAULT AND WARNING CODES

7.1 Fault Codes

In the event of a fault, the inverter switches off and a fault code appears on the display. The last fault that occurred is stored in

parameter P140, the preceding faults in P141 - P143.. e.g. ‘0004’ indicates that the last fault was F004

Fault Code Cause Corrective Action

F001

Overvoltage

Check whether supply voltage is within the limits indicated on the rating

plate.

Increase the Ramp-down time (P003) or apply braking resistor (option).

Check whether the required braking power is within the specified limits.

F002

Overcurrent

Check whether the motor power corresponds to the inverter power.

Check that the cable length limits have not been exceeded.

Check motor cable and motor for short-circuits and earth faults.Check

whether the motor parameters (P080 - P085) correspond with the motor

being used.

Check the stator resistance (P089).

Increase the ramp-up time (P002).

Reduce the boost set in P078 and P079.

Check whether the motor is obstructed or overloaded.

F003

Overload

Check whether the motor is overloaded.

Increase the maximum motor frequency if a motor with high slip is used.

F004

Overheating of motor

(monitoring with PTC)

Check if motor is overloaded.

Check the connections to the PTC.

Check that P087 has not been set to 1 without a PTC being connected.

F005

Inverter overtemperature

(internal heatsink sensor)

Check that the ambient temperature is not too high.

Check that the air inlet and outlet are not obstructed.

Check that the inverter’s integral fan is working

F008

USS protocol time-out

Check the serial interface.

Check the settings of the bus master and P091 - P093.

Check whether the time-out interval is too short (P093).

F009

Undervoltage

Check whether the supply voltage is within the limits indicated on the rating

plate.

Check the supply is not subject to temporary failures or voltage reductions.

F010

Initialisation fault

Check the entire parameter set. Set P009 to `0000' before power down.

F011

Internal interface fault

1

Switch off power and switch on again.

F012

External trip

Source of trip is digital input (configured as an external trip input) going low

- check the external source.

F013

Programme fault

1

Switch off power and switch on again.

F016

Sensorless vector control unstable

Try calibrating the stator resistance (set P088 to 1 and RUN).

Alternatively try re-adjusting the sensorless vector control loop gain (see

P386).

F030

PROFIBUS link failure

Check the integrity of the link.

F031

PROFIBUS to inverter link failure

Check the integrity of the link.

F033

PROFIBUS configuration error

Check the PROFIBUS configuration.

F036

PROFIBUS module watchdog trip

Replace PROFIBUS module

F057

Delayed Trip (See P057)

P051 to P055 or P356 = 20 and trip input has remained low for longer than

the time set in P057

F074

Motor overtemperature by I

2

t

calculation

Trip occurs only if P074 = 4, 5, 6 or 7. Check that the motor current does

not exceed the value set in P083 and P086.

F075

Over current during ramping down

Increase the ramp down time (P003).

F101

Internal interface fault

1

Switch off power and switch on again.

F105

Inverter overtemperature (internal

sensor)

Check that the ambient temperature is not too high.

Check that the air inlet and outlet are not obstructed

Check that the inverter’s integral fan is working

Loading...

Loading...