6 MJ-4A & MJ-4B Control Panel Automatic Mode

48 Siemens Energy, Inc.

6.3 Voltage Sensing and Correction

Voltage Sensing

The control program monitors the regulator output voltage

signal from one of the following sources:

• a voltage transformer, “VT” [also known as a potential

transformer or “PT”], integral to the regulator, which

is turns-ratio corrected to deliver 120 VAC at the nom-

inal system voltage.

• the utility winding of the regulator, which generally

requires correction to deliver 120 VAC at the nominal

system voltage.

The control program senses regulator output (i.e., “load”)

voltage depending on power flow operating mode (see

Table 6.2):

Since the control program routinely senses both the volt-

age transformer and the utility winding, it is a straightfor-

ward process for the control program to select which

source is “active” (depending on power flow mode and

regulator design).

If a voltage transformer is not installed on the regulator,

then the control will calculate the voltage on that side of

the regulator based on the utility winding voltage and tap

position.

Software Voltage Measurement Correction

The monitored output voltage is scaled appropriately to

the nominal basis voltage in two steps. The first voltage

scaling is performed through a step-down transformer.

The second scaling takes place in the software algorithm

after the voltage is converted to a numeric representation.

Software scaling corrects the nominal input voltage level

to the numeric representation of the basis voltage. The

basis voltage value is user configurable. The choices are

115, 120 and 125 V. The default basis voltage is 120 V.

6.4 Voltage Limit Control

The voltage limit control (VLC) function monitors regulator

output voltage and compares it to maximum and mini-

mum voltage limit set points. If the VLC function is active,

the control program inhibits tap changes that would cause

the voltage to go above the VLC upper or below the VLC

lower voltage. If VLC is activated while the voltage is out-

side of the VLC limit range, the tap position is incre-

mented/decremented until the voltage is within the

defined VLC range.

Limiting and/or runback may occur if one of the following

happens:

1. The source voltage changes dramatically,

2. The load on the regulator changes significantly, or

3. The VLC function is enabled when the limit conditions

are exceeded.

Note: The VLC function uses the Vld (i.e., the load

voltage at the regulator

) to determine whether

or not to limit or runback. The VLC algorithm

senses one regulator bushing for forward

power flow, and the other regulator bushing for

reverse power flow. (See Forward/Reverse

Operation modes, below).

The maximum voltage limit set point is adjustable from

106.0 volts to 134.0 volts in 0.1 volt steps. The minimum

voltage limit set point is adjustable from 106.0 volts to

134.0 volts in 0.1 volt steps. The control program will not

allow these limits to be set so that they overlap one

another.

If regulator output voltage falls outside limits, VLC acts to

return regulator voltage within limits. Return begins imme-

diately, (i.e., without regard to the time delay setting),

while avoiding a hunting condition, (i.e., VLC will not force

a tap change which would activate the basic control algo-

rithm and force the regulator outside limits once again).

VLC activates when load voltage is within one volt of the

upper/lower limit to prevent the voltage from going out-

side prescribed limits.

6.5 Reverse Power Flow

Systems where power flow reversals occur have unique

regulation control requirements. For systems of this type,

the MJ-4

senses the reversal and adjusts its operation

accordingly. When power flow direction changes, the

MJ-4A & MJ-4B control algorithm takes the following fac-

tors into account:

1. Power Flow direction,

2. Forward or Reverse operating mode, and

3. Power Flow Mode as selected from the <CONFIG-

URE> Menu. These factors are discussed in greater

detail below:

6.5.1 Power Flow Direction

The microprocessor determines power flow direction by

continually monitoring the real power (kW) reading and the

real component of current. The real component of current

represents the component of the current which is in

phase with the load voltage signal.

The MJ-4

Control Panel indicates forward power flow

when the real power (kW) is positive and the real compo-

nent of current is greater than 1% of the full scale current.

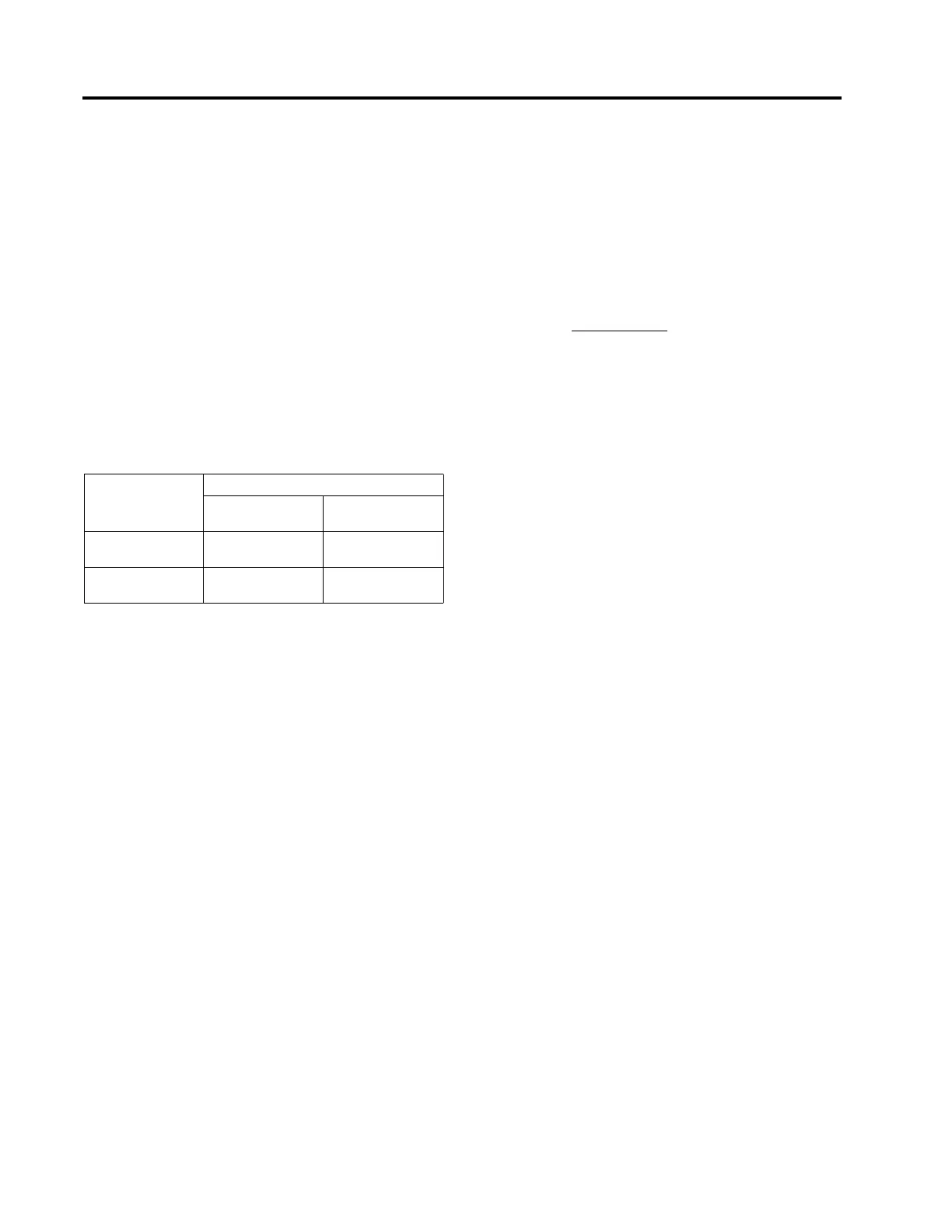

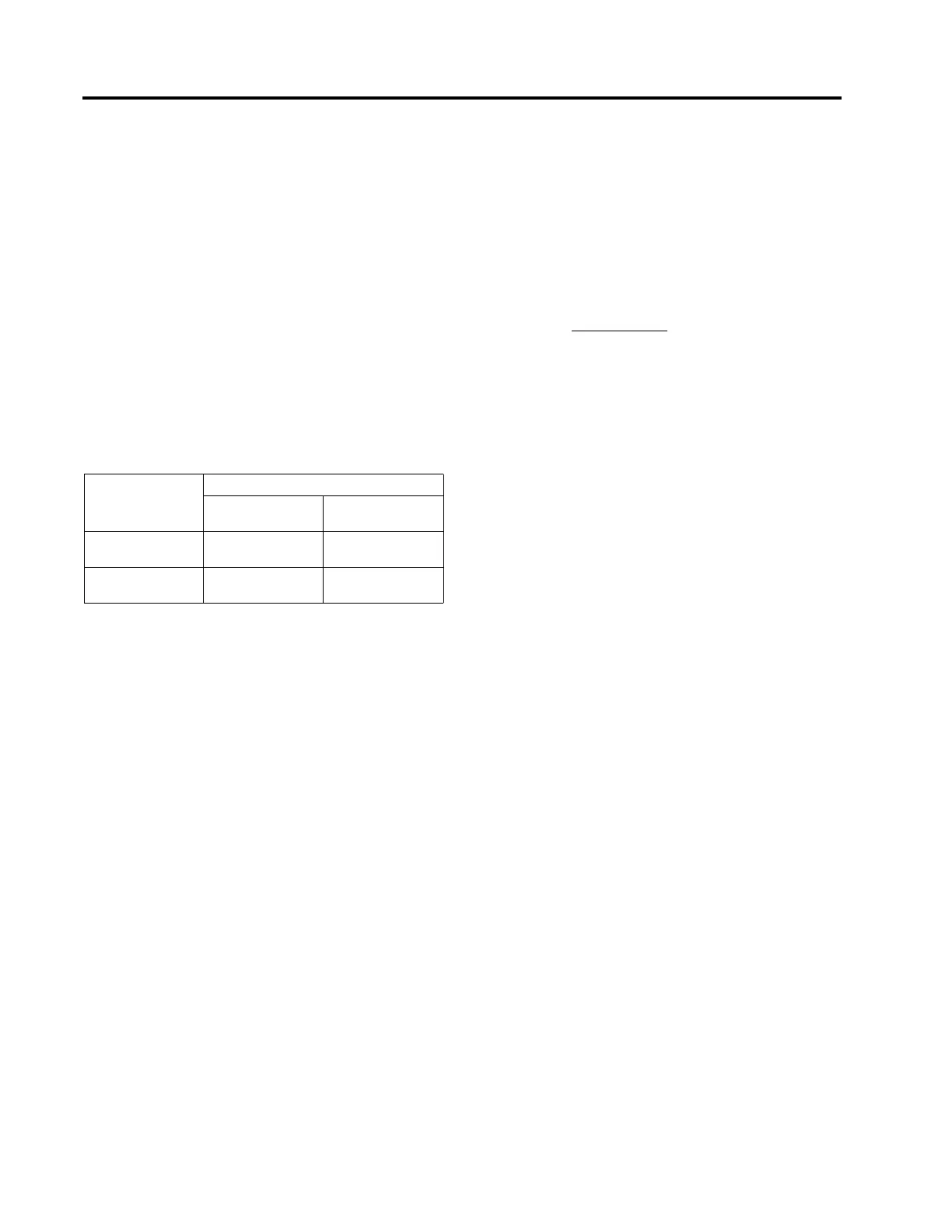

Table 6.2 Regulator Output Voltage Sensing

Regulator Design

ANSI Type

Winding Used for Voltage Sensing

Forward Power

Flow Operation

Reverse Power

Flow Operation

A (Straight) Voltage

transformer

Utility winding

B (Inverted) Utility winding Voltage

transformer

Loading...

Loading...