Do you have a question about the Siemens SIMODRIVE base line A and is the answer not in the manual?

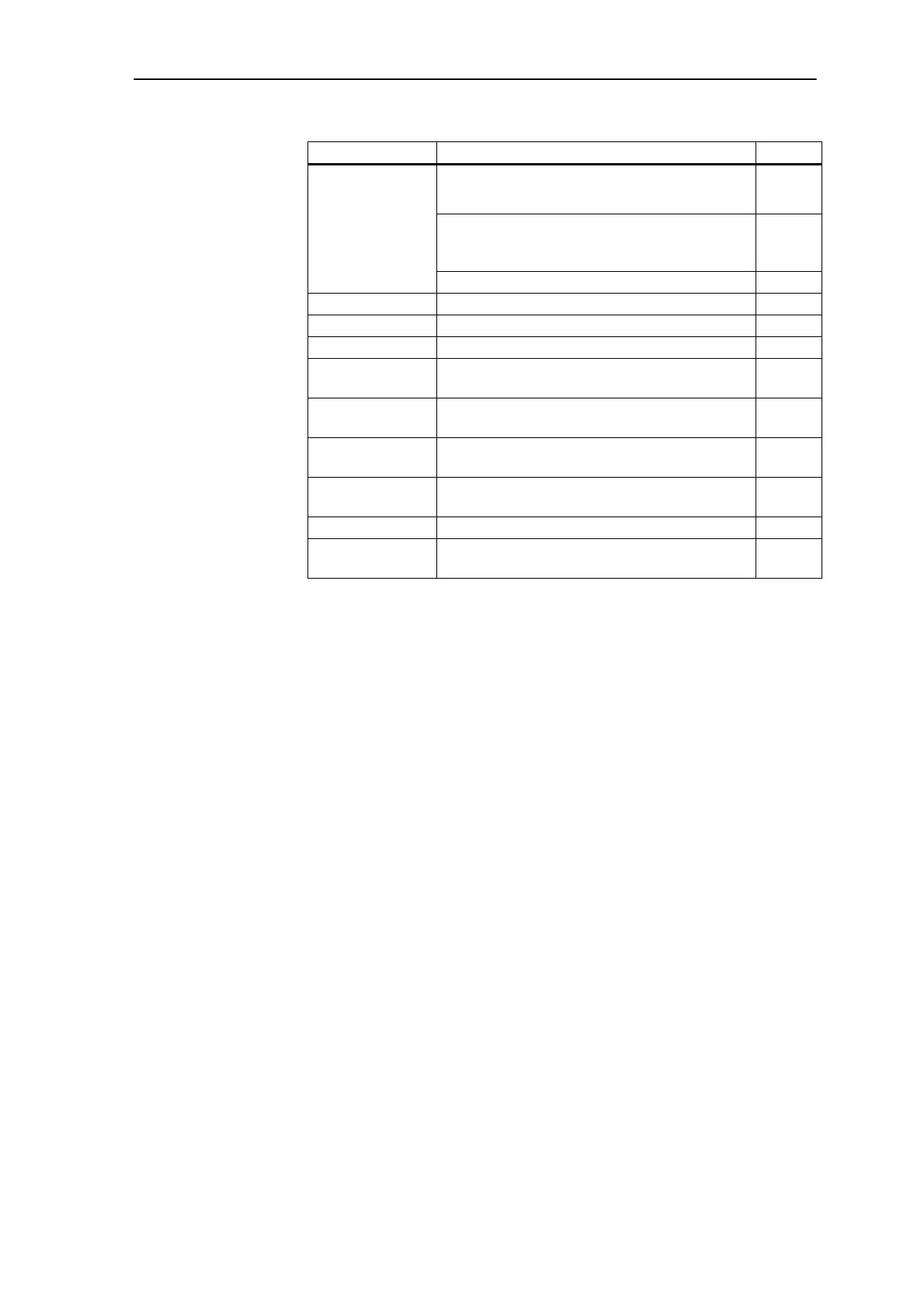

| Type | SIMODRIVE base line A |

|---|---|

| Category | Controller |

| Cooling method | Air cooling |

| Communication interface | PROFIBUS |

| Protection features | short circuit |

| Storage temperature | -25 to +70 °C |

| Relative humidity | 5% to 95% (non-condensing) |

| Installation altitude | Up to 1000 m above sea level |

| Input voltage | 3-phase AC 380-480V ±10% |

Details the various internal modules and components that make up the SIMODRIVE base line A.

Specifications for connected load, mechanical data, environment, transport, and protection.

Details on basic versions, configurations, and ordering of accessories for SIMODRIVE base line A.

Definitions for Danger, Warning, Caution, and Notice levels of risk.

Specifies requirements for qualified personnel and proper use of the equipment.

Step-by-step guide for mounting and installing the SIMODRIVE base line A unit.

Diagrams and specifications for the physical mounting dimensions and clearances required.

Overview of accessories like fuses, filters, and cables, and their installation guidelines.

Step-by-step procedure for optimizing the dynamic performance during commissioning.

Diagram showing the location of interfaces and components on the front panel of the SIMODRIVE base line A.

Illustrates the wiring of cables between the SINUMERIK 802C and SIMODRIVE base line A.

Details of various interfaces including control module and infeed module.

Details feedback, encoder, DIL switch, and enable signal interfaces on the control module.

Specifies the required pole pair number for motor and resolver configuration.

Details on setting the current controller gain (Kp) using DIP switches.

Pin assignment for the position feedback interface between servodrive and NC.

Pin assignment for the encoder interface between servodrive and servomotor.

Explanation of drift compensation using the potentiometer for nset=0.

Details on setting actual drive speed using the tachometer potentiometer.

How to set the proportional gain (Kp) of the speed controller using a potentiometer.

How to set the integral action time (TN) of the speed controller using a potentiometer.

Terminal definitions for speed setpoint and controller enable signals on the X321/X322 interface.

Diagram and guidelines for connecting the drive converter to various line supply types.

Details on grounding and enable interface terminals for the infeed module.

Schematic showing correct ground connections for the SIMODRIVE base line A in the cabinet.

Describes the drive variant for applications where highest encoder resolution is not critical.

Diagram illustrating the control process within the SIMODRIVE base line A.

Block diagram detailing the functions and signals within the infeed module.

Time diagram illustrating the sequence of enable signals in the infeed module.

Purpose of the control module for feed drives and its PI characteristics.

Details on heatsink overtemperature, I2t monitoring, and motor overtemperature protection.

Table detailing the technical parameters of SIEMENS 1FK7 servomotors.

Table showing order numbers and specifications for various 1FK7 servomotor models.

Diagrams and tables detailing the physical mounting dimensions of 1FK7 servomotors.