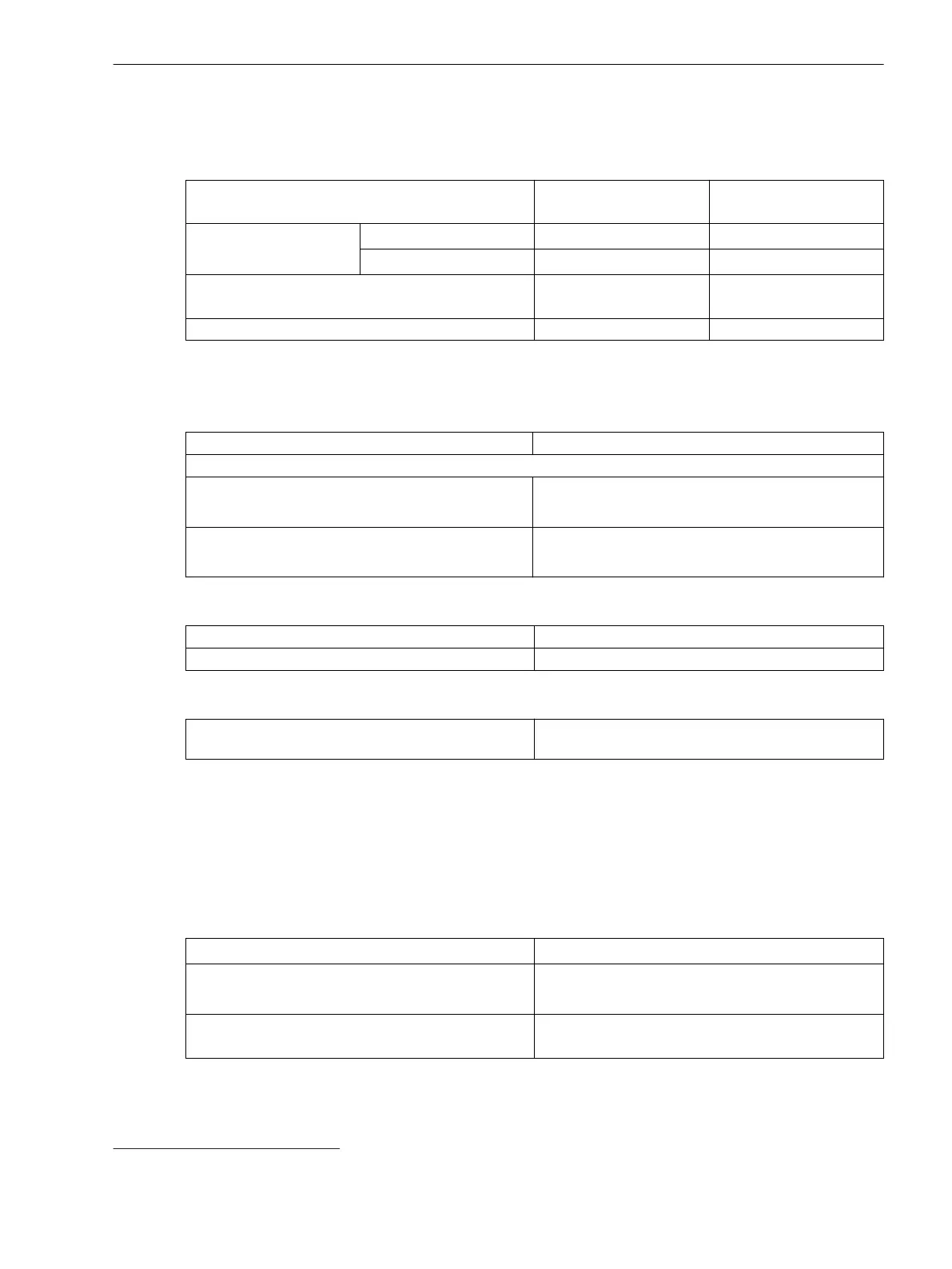

Stage with Inverse-Time Characteristic Curve

Setting Values

Method of measurement Fundamental component

RMS value

–

Threshold value

68

For I

rated

= 1 A 0.010 A to 35.000 A Increments of 0.001 A

For I

rated

= 5 A 0.05 A to 175.00 A Increments of 0.01 A

Dropout Disk emulation

Instantaneous

–

Time multiplier 0.05 to 15.00 Increments of 0.01

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout 95 % of 1.1 ⋅ threshold value

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Reset of the Integration Timer

Instantaneous

With dropout

Disk emulation Approx. < 0.90 ⋅ threshold value

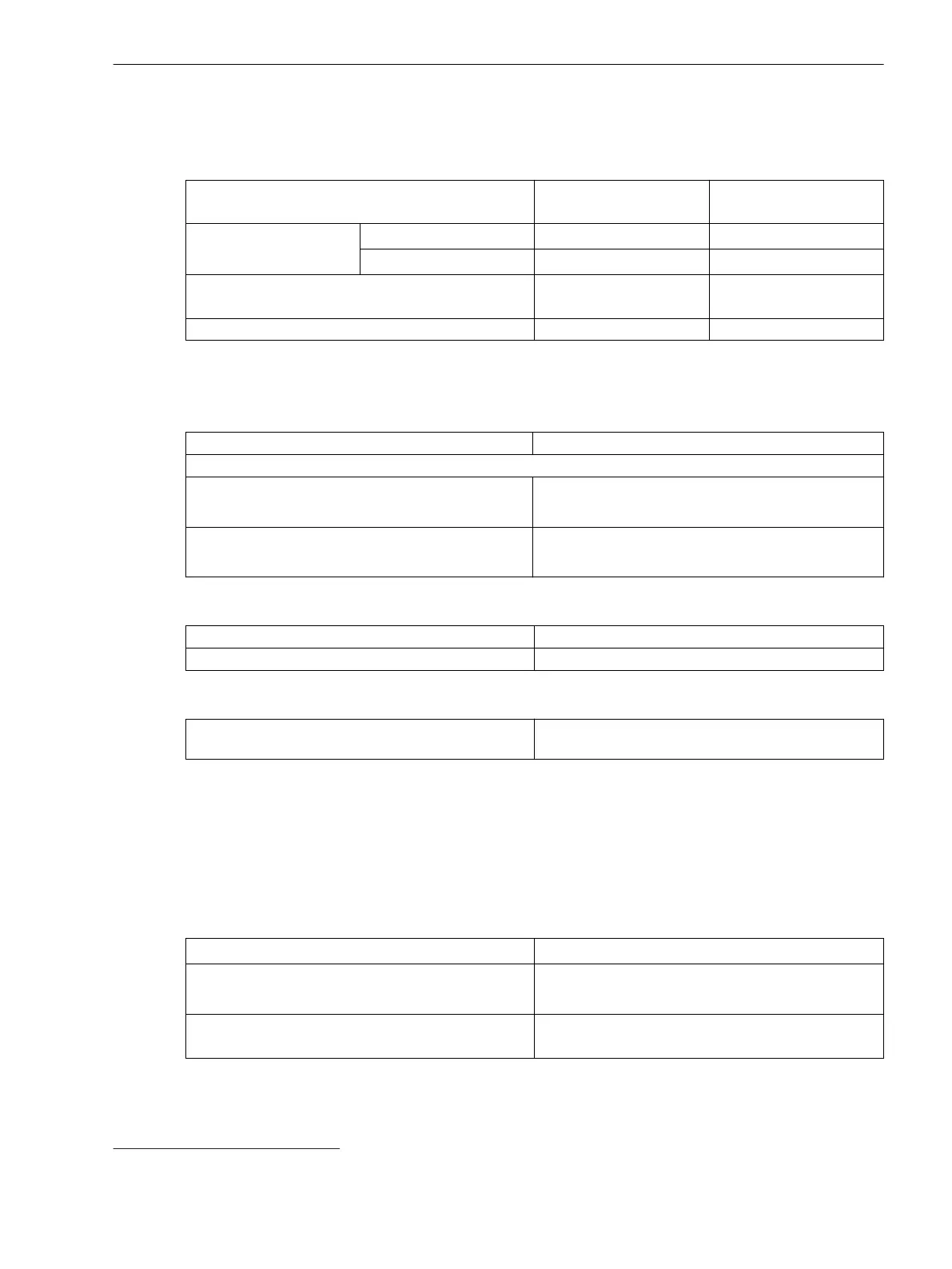

Operate Curves and Dropout Characteristic Curves According to IEC

Extension of the operate time during operation with

transformer inrush-current detection

Approx. 10 ms

The operate curves and dropout characteristic curves according to IEC can be found in the Technical Data

chapter under Inverse-Time Overcurrent Protection.

Operate Curves and Dropout Characteristic Curves According to ANSI/IEEE

The operate curves and dropout characteristic curves according to ANSI/IEEE can be found in the Technical

Data chapter under Inverse-Time Overcurrent Protection.

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

11.15

68

If you have selected the method of measurement = RMS value, do not set the threshold value under 0.1 l

rated,sec

.

Technical Data

11.15 Stage with Inverse-Time Characteristic Curve

SIPROTEC 5, High-Voltage Bay Controller, Manual 1163

C53000-G5040-C015-A, Edition 05.2018

Loading...

Loading...