11

|

Instruction Manual and Parts List

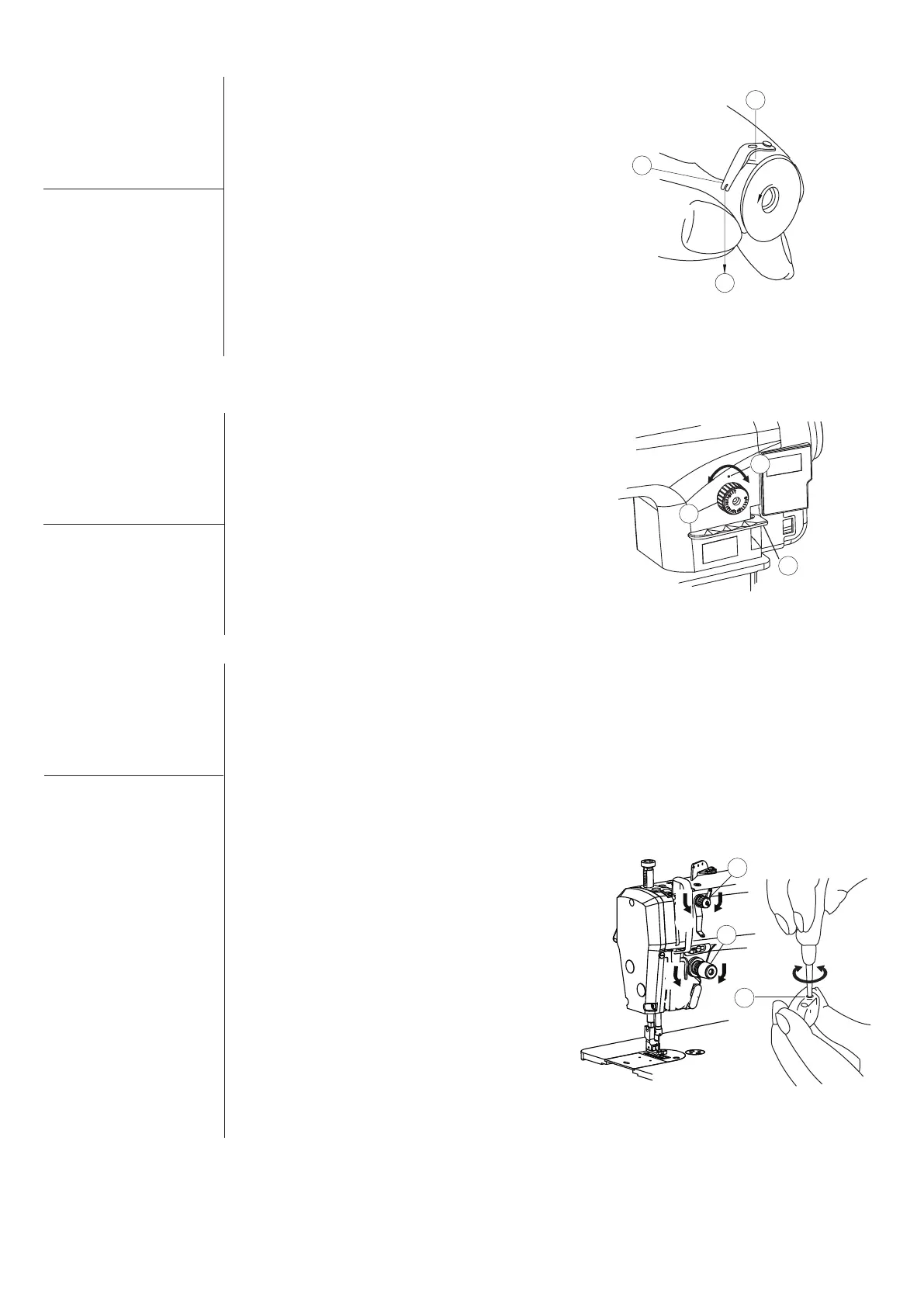

Bobbin Case

Attachment

3.8

Fix the bobbin into bobbin case

with that the thread open end is

directed to the left as observed

from you.

Pass the thread through thread slit

‘A’, and pulls it in direction ‘B’. By

doing so, the thread will pass under

the tension spring and come out

from notch ‘B’.

When pulling the thread ‘C’, the

bobbin should rotate in the direc-

tion of the arrow.

Stitch Length

Adjustment

3.9

‘2’

direction of the arrow, and align

the desired number to marker dot

‘A’ on the machine arm.

The indication of the dial is in milli-

meters.

When you want to decrease the

stitch length, press reverse lever ‘1’

while turn stitch dial ‘2’ in the direc-

tion of the arrow.

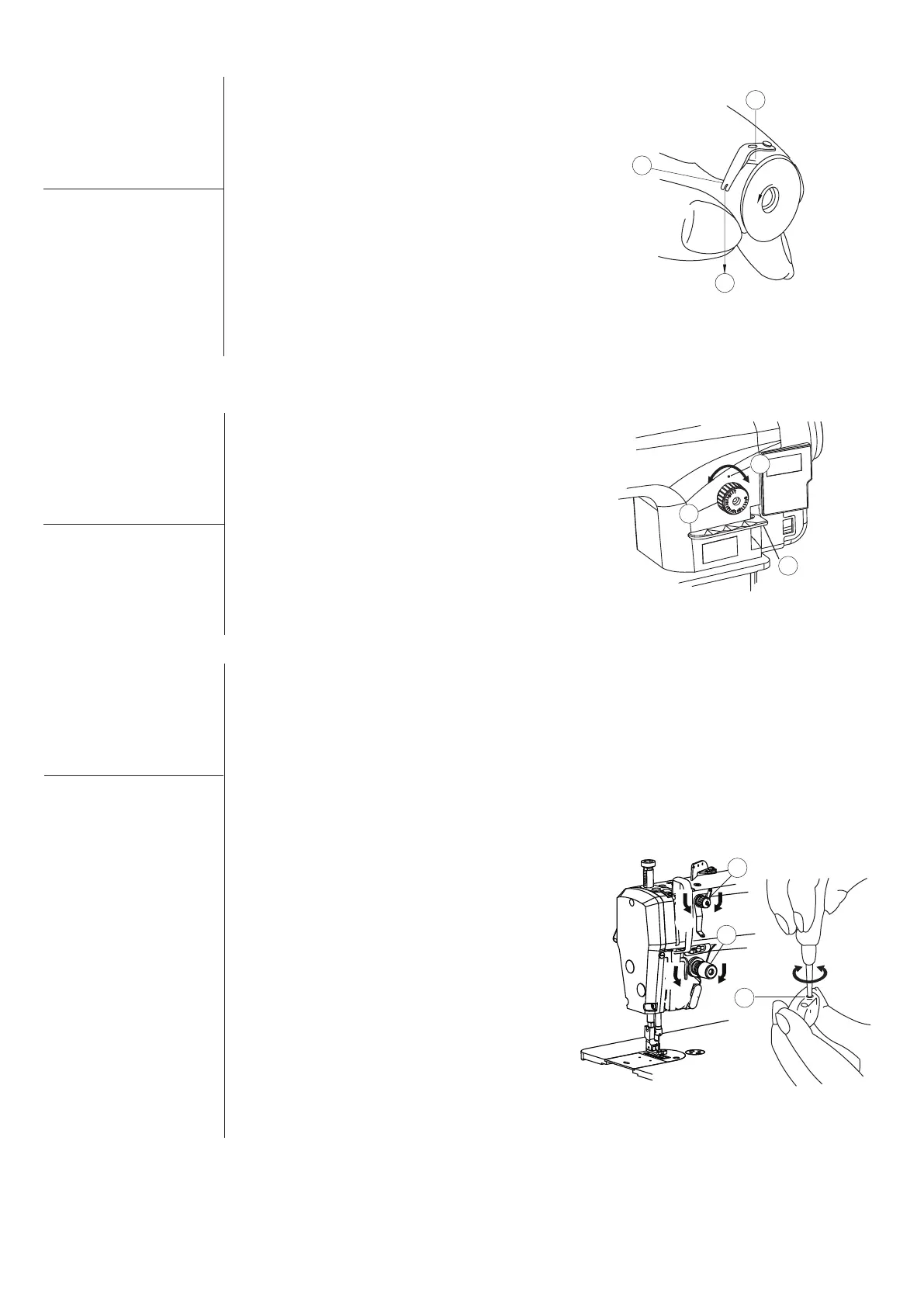

Thread Tension

Adjustment

3.10

Adjusting the needle thread tension

The tension nut ‘1’ can be adjusted

for the needle thread lengths after

trimming.

Turn the nut ‘1’ clockwise (in direc-

tion A), the length of the needle

thread will be shorter.

Turn the nut ‘1’ counter-clockwise

(in direction B), the length of the

needle thread will be longer.

Adjust the tension of needle thread

by tension nut ‘2’ according to

different sewing conditions.

Turn the nut ‘2’ clockwise (in direc-

tion C), the needle thread tension

will be increased.

Turn nut ‘2’ counter-clockwise (in

direction D), the needle thread

tension will be decreased.

Figure 15

Figure 13

Adjusting the bobbin thread tension

Turn the screw ‘3’ clockwise (in

direction E), the bobbin thread

tension will be increased.

Turn the screw ‘3’ counter-

clockwise (in direction F), the

bobbin thread tension will be

decreased.

Figure 14

A

3

E F

C

A

B

C

1

Press revrese lever ‘1’, turn stitch dial

1

B

D

2

2

A

Integrated Energy Saving Direct Drive Motor Lockstitch Sewing Machine

Loading...

Loading...