— 29 —

TROUBLESHOOTING

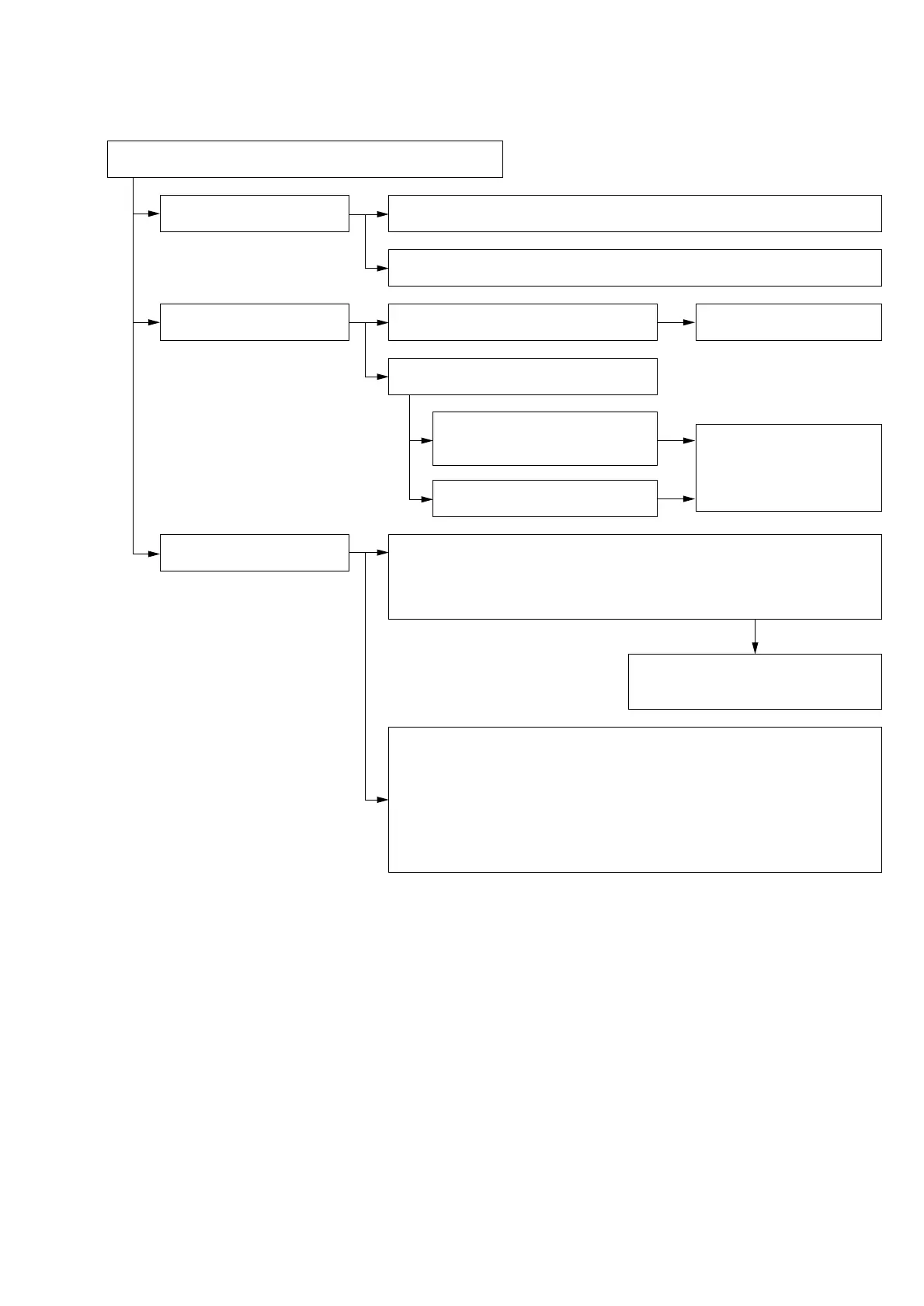

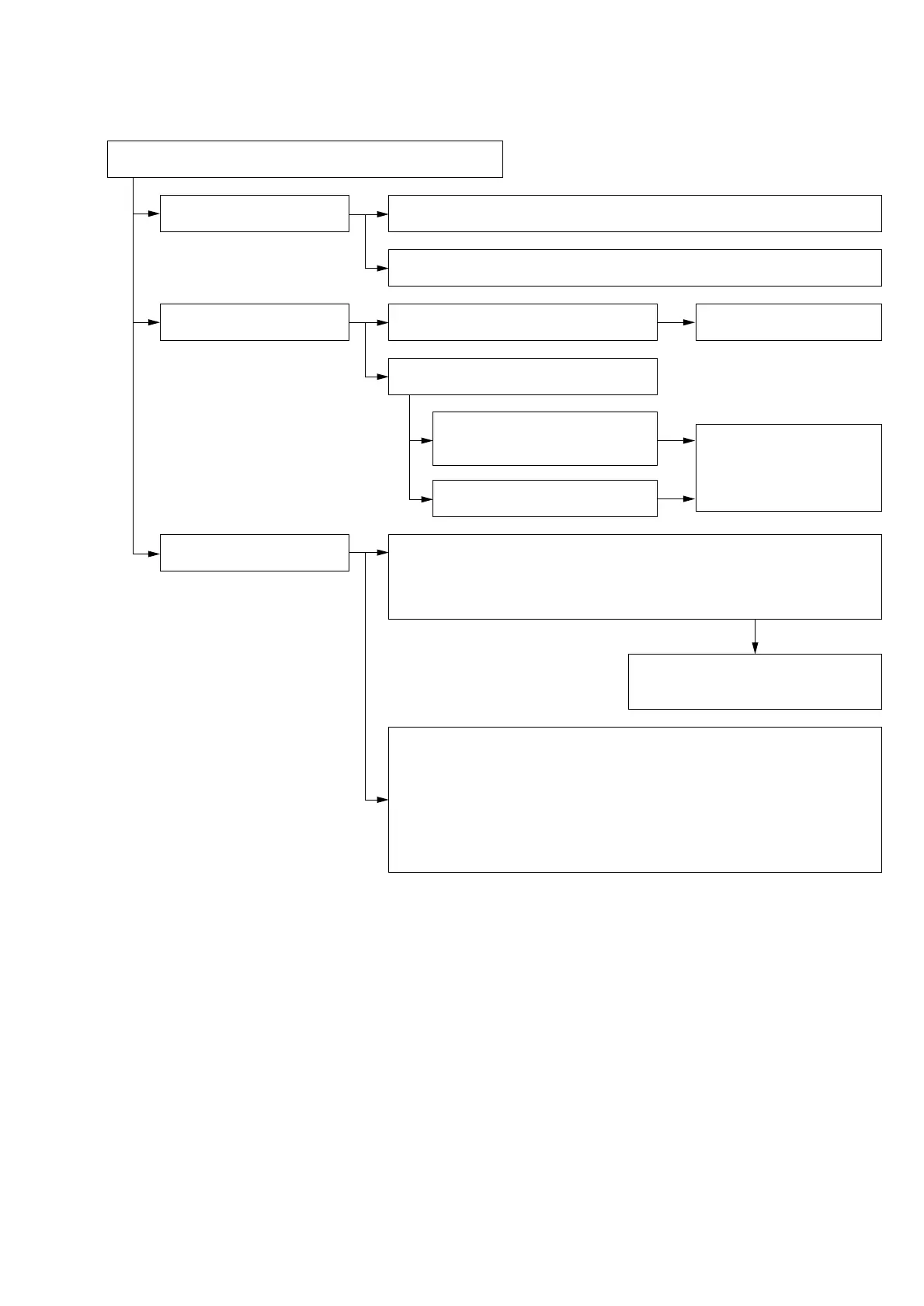

1. FLOW OF TROUBLE ANALYSIS AND REPAIR

Flow of Trouble Analysis and Repair of DDX-G2100

1. Saving the Trouble Status

a. Confirm and save the error log using Error Log File.

Analyze the error log contents referring to the separate error code table.

b. Create a backup file of the EEPROM using EEPROM Menu.

It helps to recover the present status without fail.

2. Analysis and Repair due to

Mechanical Causes

a. Check if any errors can be noticed when

viewing the outside appearance.

Replace the parts as required.

Check if there is any errors

such as some parts do not

start working, or abnormal

sound is heard, etc..

Replace the parts as required.

b. Check the operational errors as follows.

3. Analysis and Repair due to

Electrical Causes

a. Analyze the errors by performing the electrical adjustment.

Perform all the adjustment items of the electrical adjustment.

Do not perform [EEPROM Initialize].

Go through the [SKEW Adjust] for watching the movement of the machine but not

performing any adjustments.

b. When the optical unit (OP unit) is replaced:

Initialize all the data using [EEPROM Initialize]. Then start the electrical adjustment.

Because all the discrete parts are known to be good, other adjustments are

expected to be performed without any trouble if the [SKEW Adjust] is performed

correctly. Result of the [SKEW Adjust] is judged by the items [RF Jitter Check] and

[Self RF Jitter Check].

If result is found to be unacceptable, perform the [SKEW Adjust] again. If the error

cannot be solved still, return the optical unit (OP unit) to the machine and make an

attempt replace the electrical printed circuit boards.

Check if the error reappears or not.

Create a summary of default items.

Is the optical unit (OP unit) defective?

Perform operational check by reading

CD using SKEW Adjust

(Check only without adjustment)

Make an attempt of CD-R seek

Using Seek Check

Loading...

Loading...