112 MS 661, MS 661 C-M

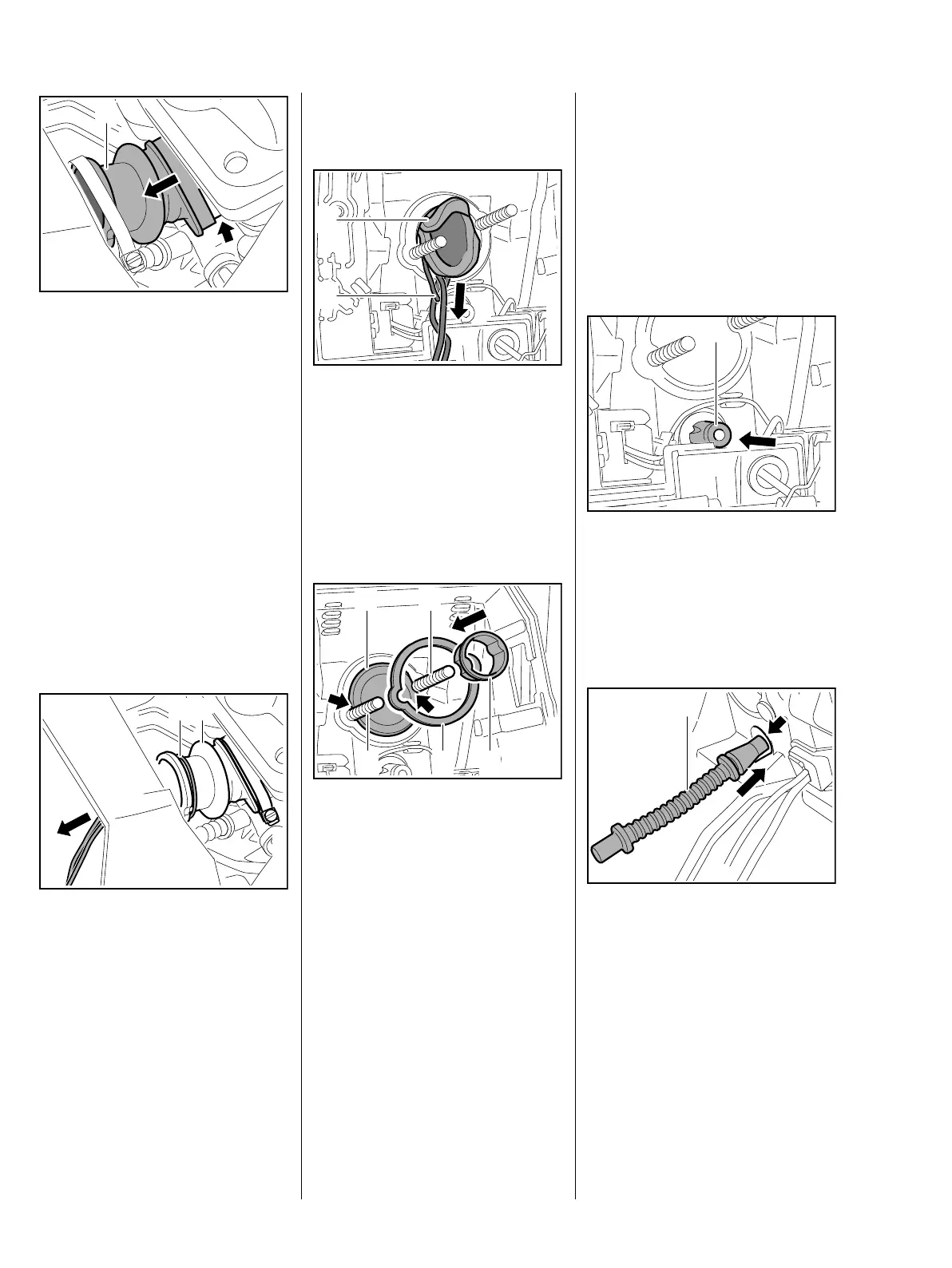

: Pull the manifold (1) off the intake

stub (arrow).

– Inspect the intake manifold and

replace it if necessary – even

very minor damage can cause

engine running problems, b 3.7

The sealing faces must be in perfect

condition. Always replace

components with damaged sealing

faces.

Installing

– Install manifold on cylinder,

b 6.5

– Coat the outside of the manifold

flange with STIHL press fluid,

b 16

: To pull the manifold flange (1)

through the intake opening, wind

a piece of string (2) (about 15 cm

long) around the flange and pass

the ends of the string through the

intake opening.

1

1166RA350 TG

1

1166RA351 TG

2

Take care to ensure that the washer

in the manifold is not damaged or

displaced.

– Press the tank housing against

the manifold and hold it there.

: Grip the ends of the string (2) and

pull the manifold flange (1)

through the opening.

– Remove the string.

: Position the manifold flange (1) –

its recesses (arrows) must locate

against the studs (2).

: Fit the washer (3) and push the

sleeve (4) into the manifold

flange (1).

– Install the carburetor, b 13.4

– Reassemble all other parts in the

reverse sequence.

1

2

1166RA352 TG1166RA068 TG

1

2

2 43

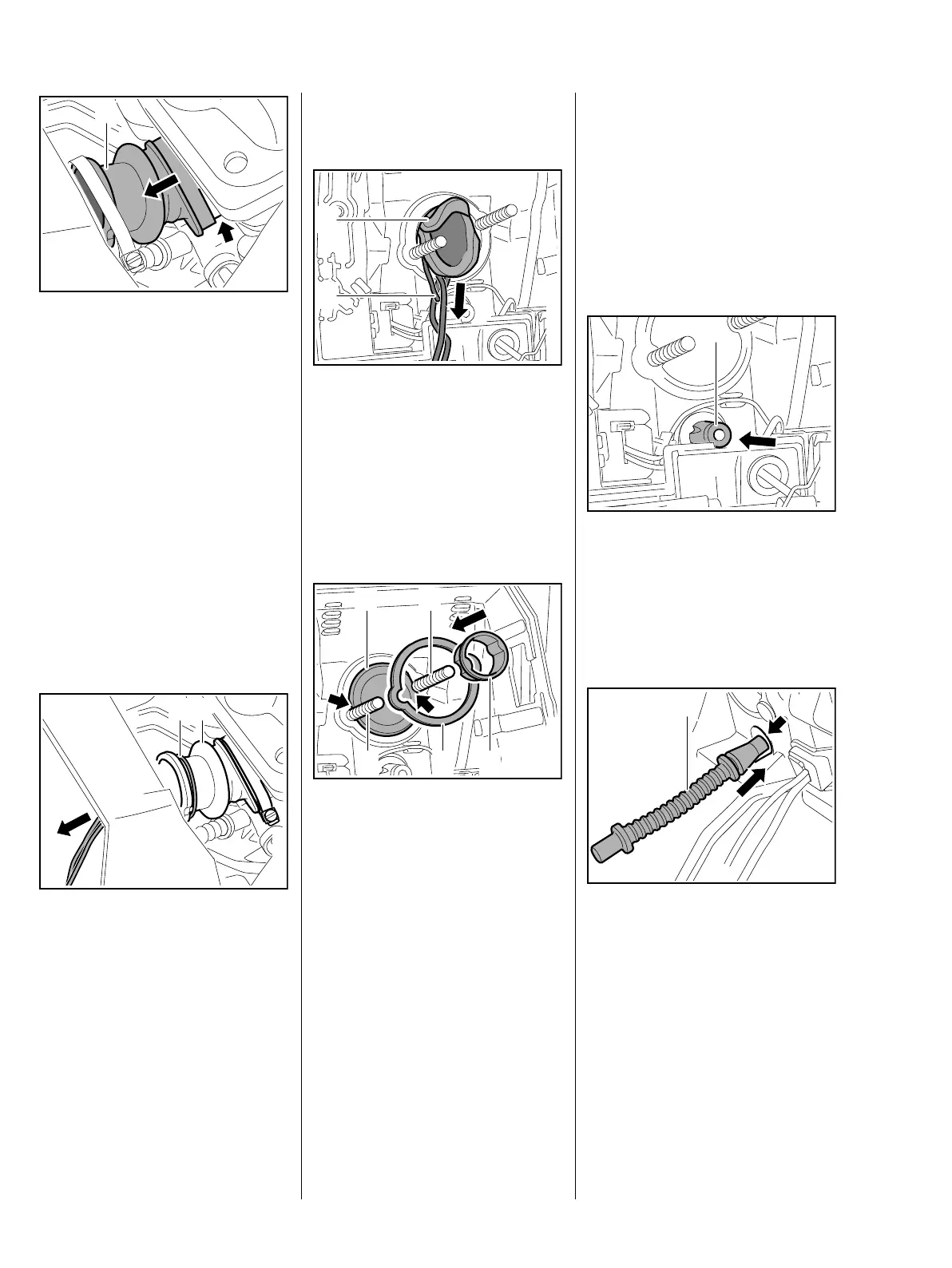

13.9.1 Impulse Hose

A damaged impulse hose can

cause engine running problems.

– Remove the carburetor, b 13.4

– Remove the tank housing,

b 13.11.4

: Pull the impulse hose (1) out of

the tank housing in the direction

of the cylinder.

– Check the impulse hose and

replace if necessary.

– Coat tapered outside of new

impulse hose with STIHL press

fluid, b 16

: Push tapered end of impulse

hose (1) through the hole (arrow)

and push it home until it is

properly seated.

1166RA354 TG

1

Loading...

Loading...