36 MS 661, MS 661 C-M

Installing

– Heat area of bearing seat to

about 160°C (320°F).

: Position the ball bearing so that

its open side (balls visible) faces

the inside of the crankcase and

then press it home as far as stop.

This operation must be carried out

quickly because the bearing

absorbs heat and begins to expand.

– Check that the bearing is properly

seated. If necessary, use

press arbor 1120 893 7200 to

press the bearing fully home.

Clutch side of crankcase

The oil seal is seated in the ball

bearing and does not need to be

removed separately.

– Check and clean the crankcase

or replace if necessary.

1166RA086 TG1166RA087 TG

– If this half of the crankcase is in

order, install a new ball bearing.

– Heat area of bearing seat to

about 160°C (320°F).

When this temperature is reached,

the ball bearing drops out together

with the oil seal – if necessary, use

press sleeve 1129 893 2400 to

press out the ball bearing through

the oil pump.

Installing

As the clutch side of the crankcase

has no stop in its bearing seat, the

mounted oil pump is used as a stop.

– Heat area of bearing seat to

about 160°C (320°F).

: Position the ball bearing so that

the oil seal's seat faces the oil

pump and then press home the

ball bearing until it butts against

the oil pump.

This operation must be carried out

quickly because the bearing

absorbs heat and begins to expand.

– Check that ball bearing is

properly seated. If necessary,

use press arbor 1144 893 2400

to carefully press the bearing fully

home until it butts against the oil

pump

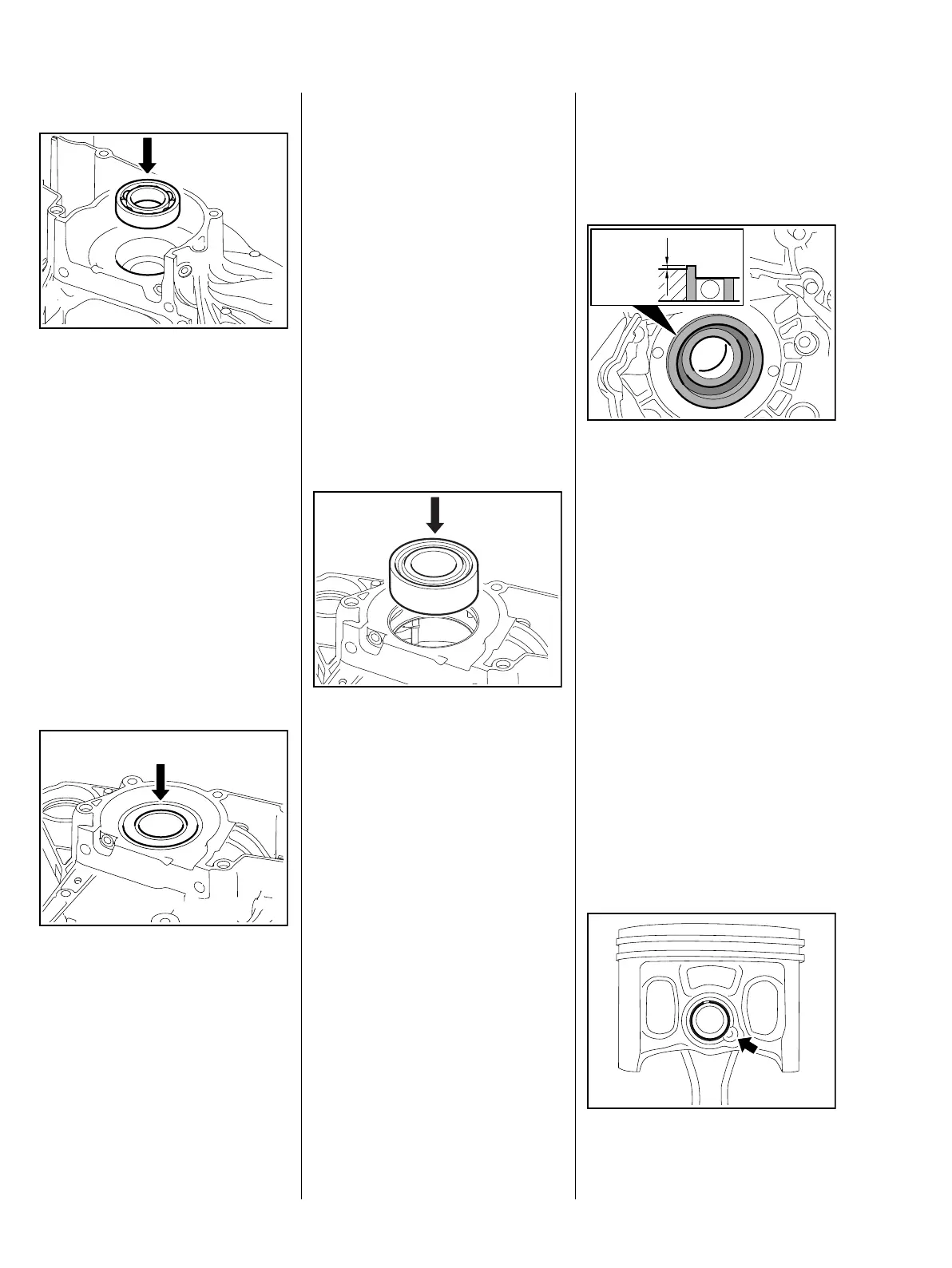

1166RA088 TG

If the oil has been removed for any

reason, carefully press home the

ball bearing with the press arbor

until its outer race projects 0.8 mm

from the bearing seat at the clutch

side.

– Remove the oil pump, b 12.3

– Install the crankshaft, b 6.6

– Install the oil seals, b 6.3

– Reassemble all other parts in the

reverse sequence.

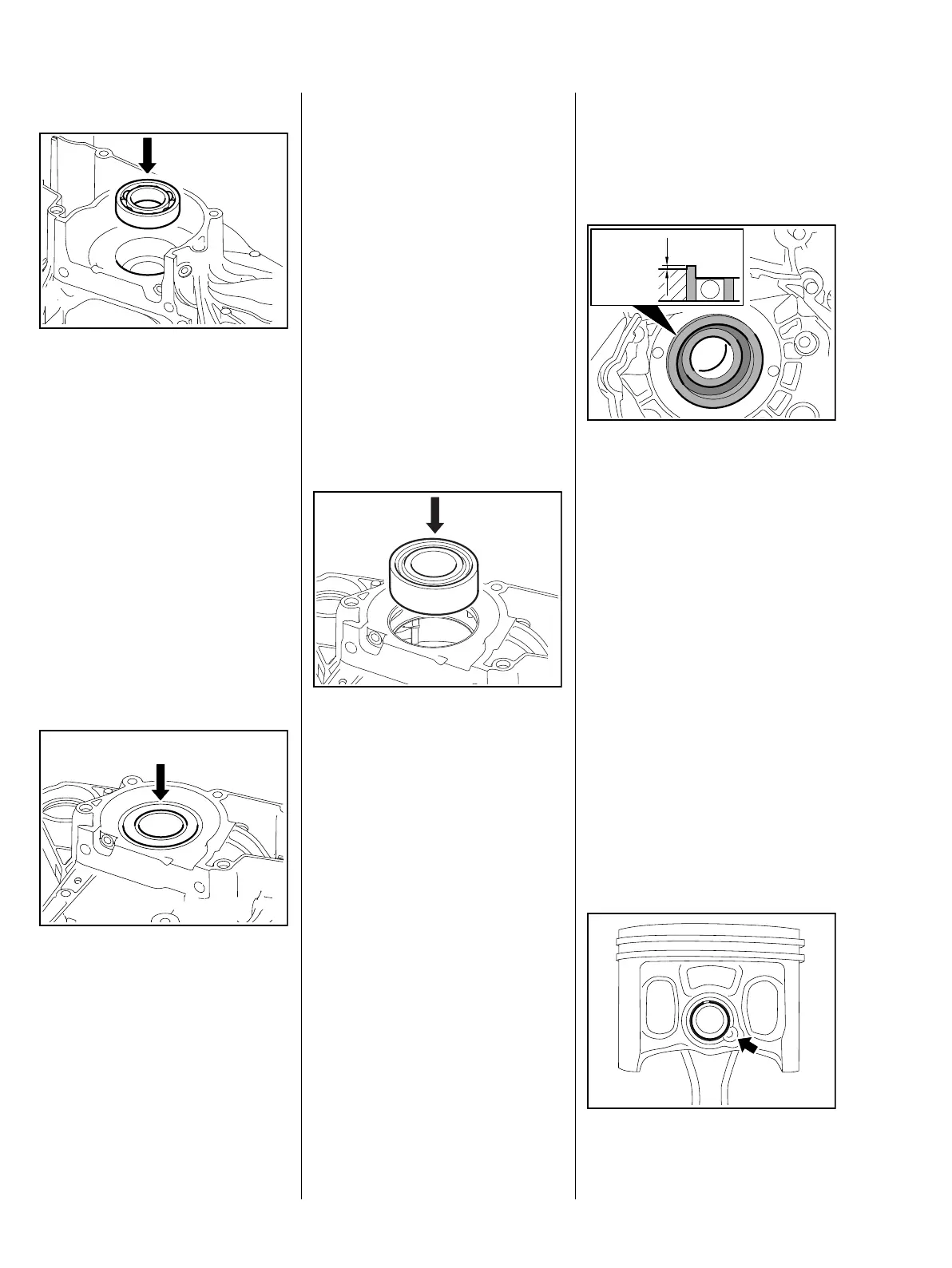

6.7 Piston

Before removing the cylinder,

decide whether or not the

crankshaft has to be removed as

well, b 6.6

– Remove the cylinder, b 6.5

It is not necessary to remove the

snap ring at the clutch side.

: Pry hookless snap ring out of

boss at ignition side – apply tool

to recess (arrow).

1166RA457 TG

0,8 mm

1166RA089 TG

Loading...

Loading...