•

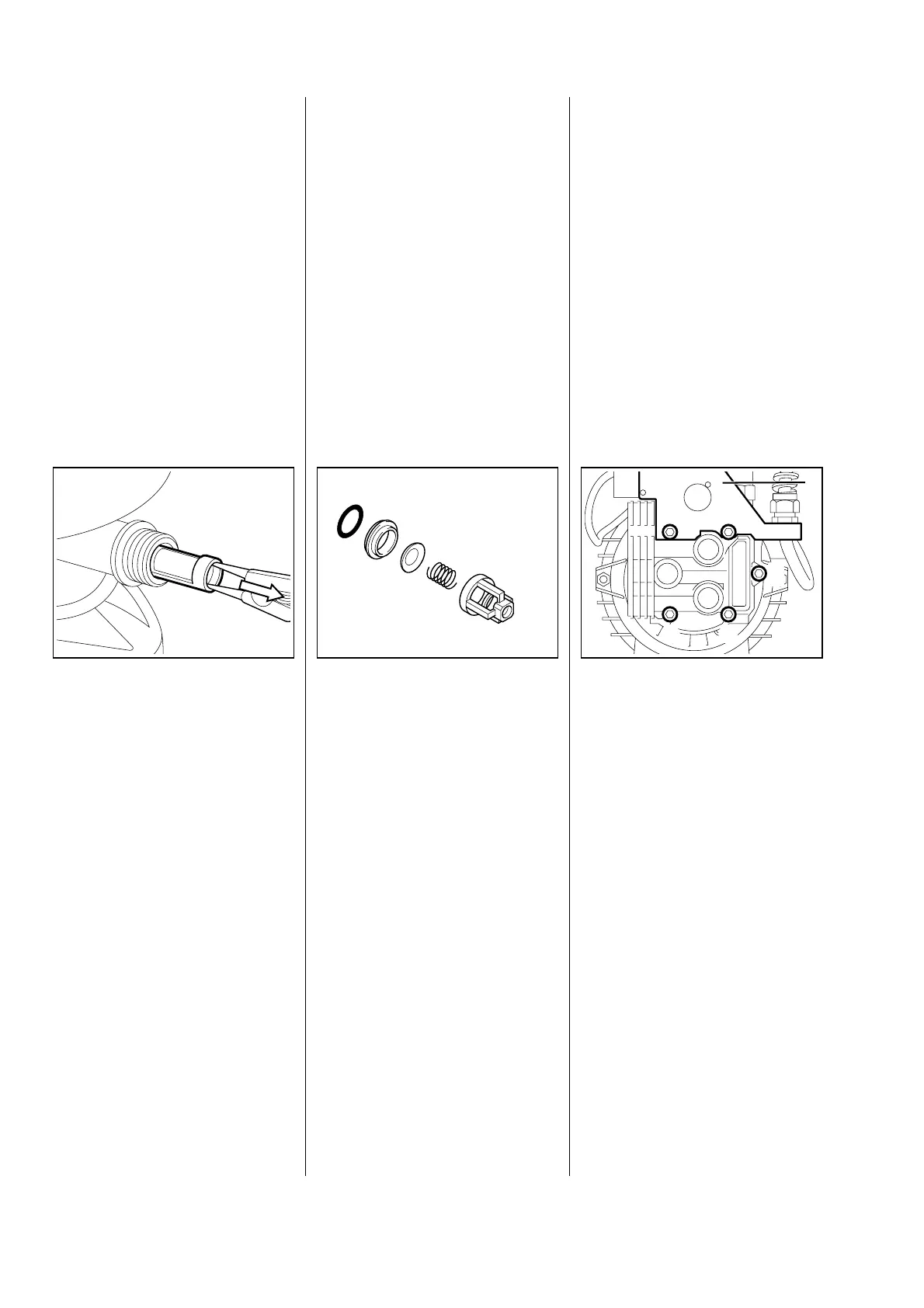

Unscrew hose connector from

water inlet (see 5.1).

•

Remove screen from intake port

with pliers, clean it and replace if

necessary.

Reassemble parts in reverse order.

- Remove shroud (see 5.1) and

motor / pump unit (see 5.2).

- Remove safety control block

(see 6.1).

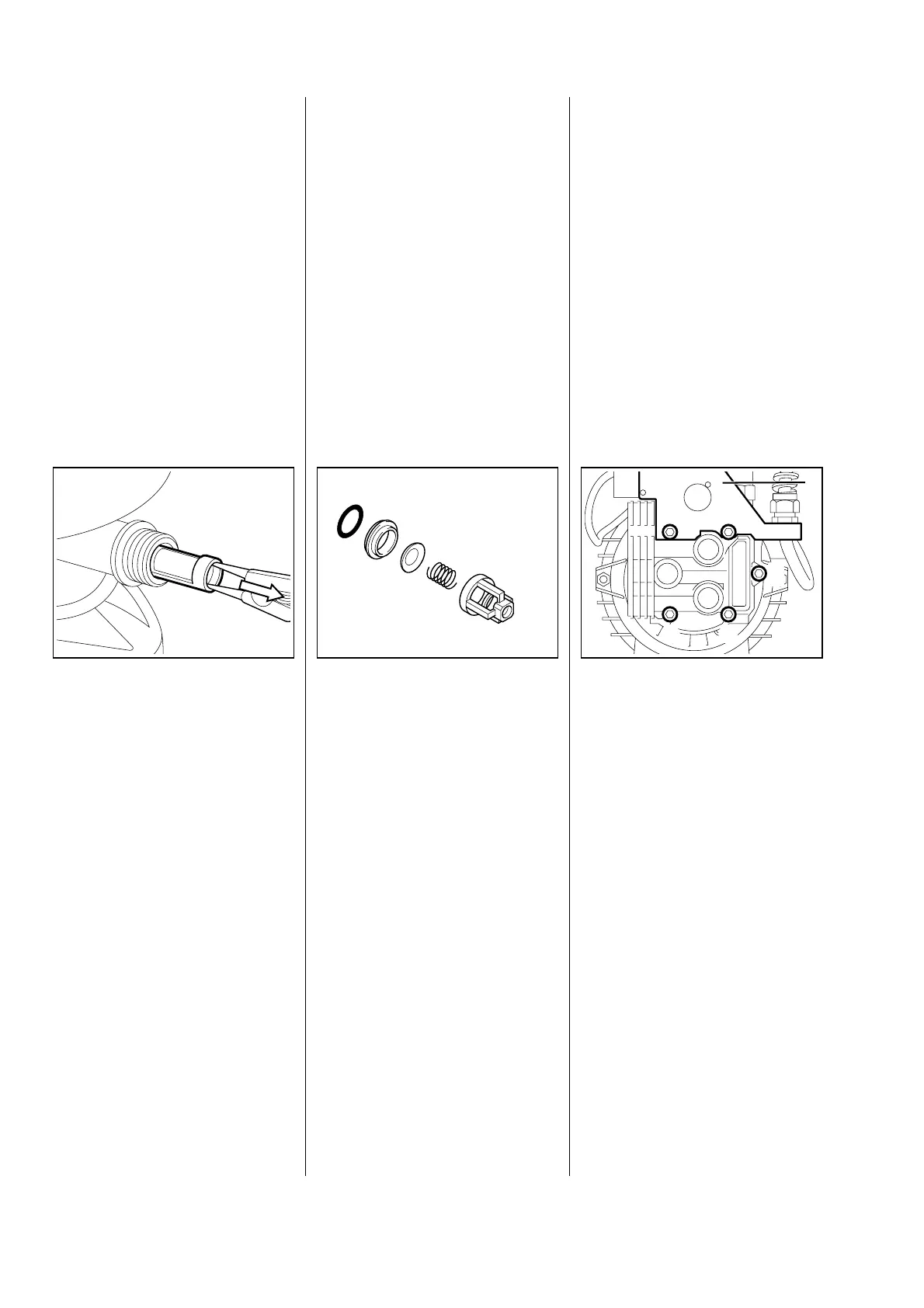

The delivery valves are removed

and installed in the same way as

on the high-pressure cleaners of

series RE 102 K, 104 K and 106 K.

Important: Different valves are

used in the high-pressure cleaners

RE 140 K, 160 K (see spare parts

list).

Note: Where possible, defective

valves should only be replaced as

a complete unit (O-ring (1), valve

head (2), plate (3), spring (4) and

cage (5)). The intake valves

must also be checked (see 7.2) if

delivery valves are soiled or

damaged.

- Check correct functioning before

installing valves.

- Remove shroud (see 5.1) and

motor / pump unit (see 5.2).

- Remove safety control block

(see 6.1).

- Remove delivery valves if

necessary (see 7.2).

•

Undo fastening screws (1).

•

Remove retaining plate (2) with

microswitch.

The intake valves are removed

and installed in the same way as

on the high-pressure cleaners of

series RE 102 K, 104 K and 106 K.

Important: Different valves are

used in the high-pressure cleaners

RE 140 K, 160 K (see spare parts

list).

- Pull valve discs out of valve

block.

621RA026 BL

621RA023 BL

1

2

3

4

5

621RA025 BL

11

1

1

2

1

7. HIGH-PRESSURPUMP

7.1 Screen in intake port

(water inlet)

7.2 Removing / installing

delivery valves

7.3 Removing / installing valve

block and intake valves

14 RE 140 K, 160 K

Loading...

Loading...