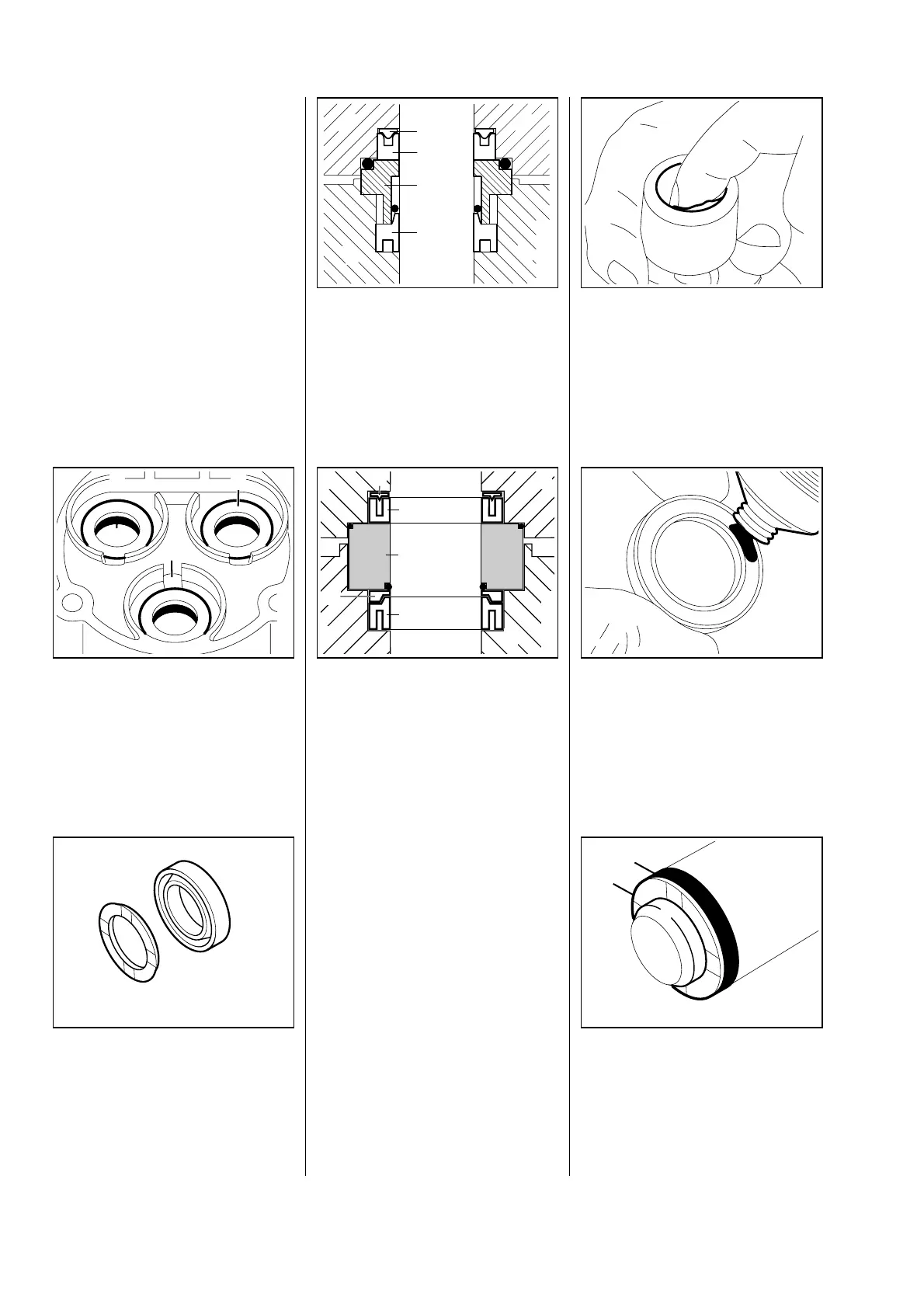

- Remove pump piston (see 7.4).

The high-pressure cups and oil

seals are removed and installed in

the same way as on the high-

pressure cleaners of series

RE 102 K, 104 K and 106 K, with

the following additional steps:

•

The oil seals (1) in the pump

housing are mounted on support

rings (2).

•

The oil seals can be prised

out by applying an implement in

the recesses (3) in the pump

housing.

RE 160 K

•

The high-pressure cups (1) in

the valve block are likewise

mounted on a support ring (2).

RE 140 K

RE 160 K

Installation position of the oil seals

and high-pressure cups:

1 High-pressure cup

2 Support ring

3 Valve block

4 Oil seal

5 Support ring

6 Pump housing

7 Guide bushing

All models

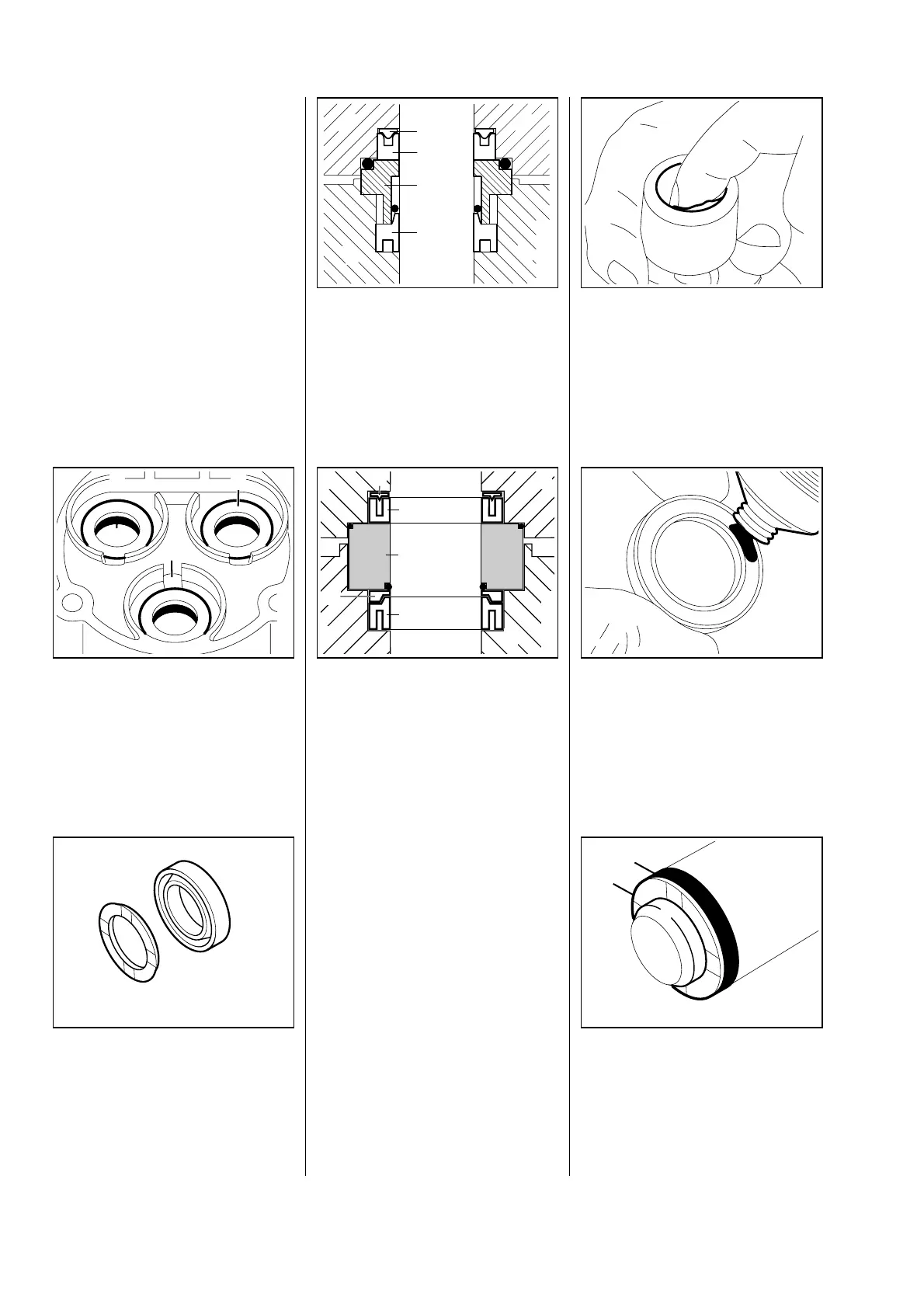

Note: Use assembly device

4726 890 2200 (assembly arbor

and sleeve) to fit the high-pressure

cups and oil seals.

Proceed as follows:

•

Coat inner surface of assembly

sleeve 4726 890 2200 with

special grease.

•

Fill the grooves of the high-

pressure cups and oil seals with

special grease 0781 145 3516.

•

Coat the new high-pressure

cup (1) with special grease

0781 145 3516 and press onto

assembly arbor 4726 890 2200

together with support ring (2).

7.6 Replacing the high-pressure

cups and oil seals

621RA043 BL

1

2

3

7

4

1

5

621RA045 BL

3 3

6

6

21RA078 BL

21RA044 BL

1

2

21RA080 BL

1

2

5

33

621RA092 KN

1

2

4

5

6

16 RE 140 K, 160 K

Loading...

Loading...