57

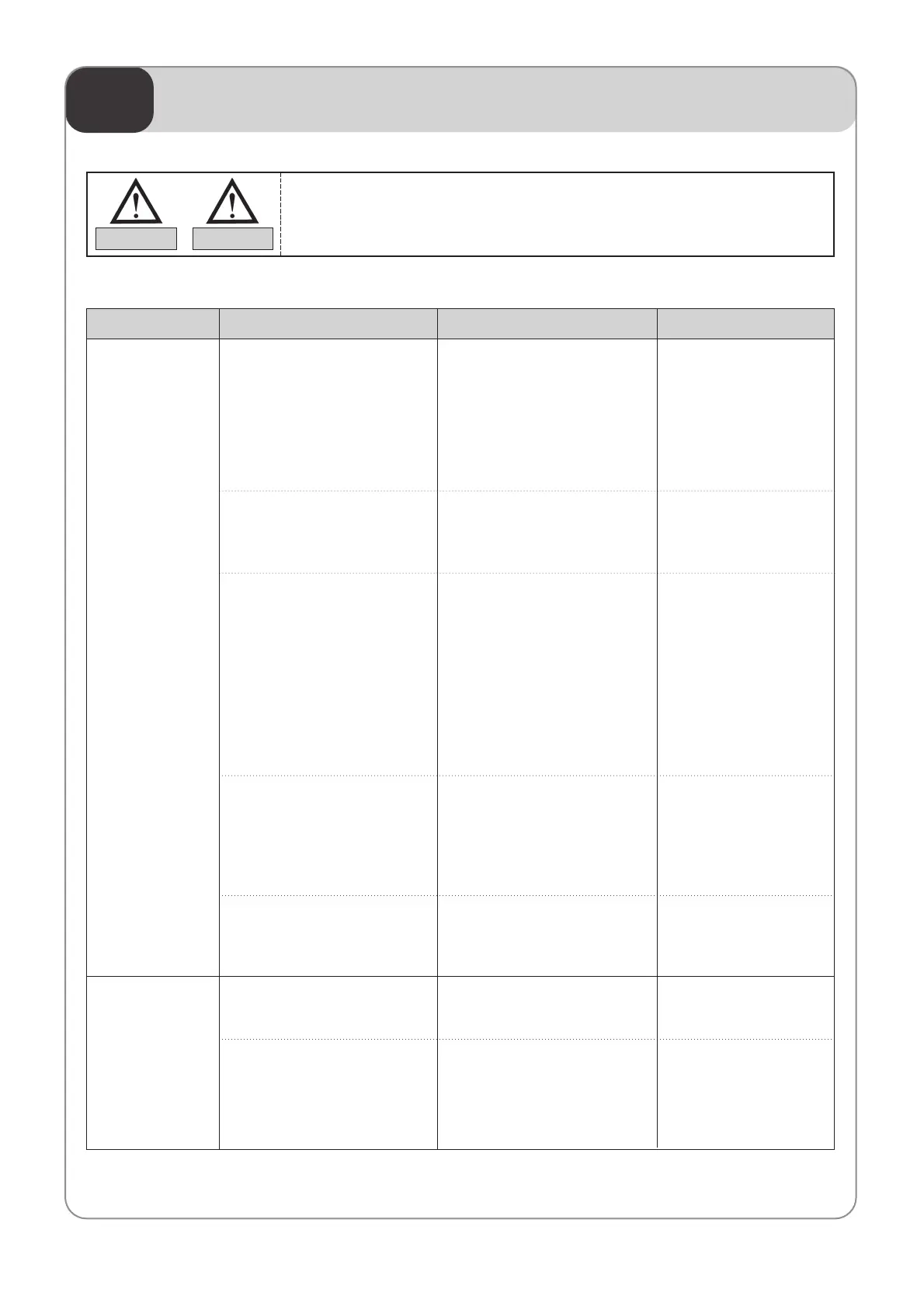

CAUSES OF TROUBLE AND TROUBLESHOOTING

11

Wrong Machine

Operation and

Movement

Wrong Stop

Position

① Excessive relaxation of the

belt tension or belt rupture

② Power outage or circuit fuse

cut

③ Failure to detect the needle

position signal or detect the

signal once

④ Frame escape from the X, Y

movement limit.

⑤ Machine does not move

even after pressing the bar

switch.

① Loose main shaft driving

belt

② Wrong encoder position and

wrong encoder

■ Adjust the belt tension and

replace the belt

■ Check whether the main

shaft motor drive fuse is

cut, and replace the fuse

■ Execute manual color

change. Locate the needle

at the highest position.

Check whether the signal

lamp (needle set and

concerned signal lamp

LED) blinks, and adjust the

half-turn film accordingly.

■ Return the frame to the

original position (within the

scope of the limit switch).

■ Check the operation status

of the limit sensor

■ Check the wiring of the

switch related to bar stitch

and the connector

■ Adjust the belt tension

■ Adjust the encoder position

or replace the encoder

■ Check the belt

depending on type of

trouble

① Main driving belt

② X-Y shaft timing

belt

Corrective Action and Check PointCause of TroubleType Remarks

When a breakdown occurs, conduct repair or check in accordance with the

safety rules.

CAUTION DANGER

Loading...

Loading...