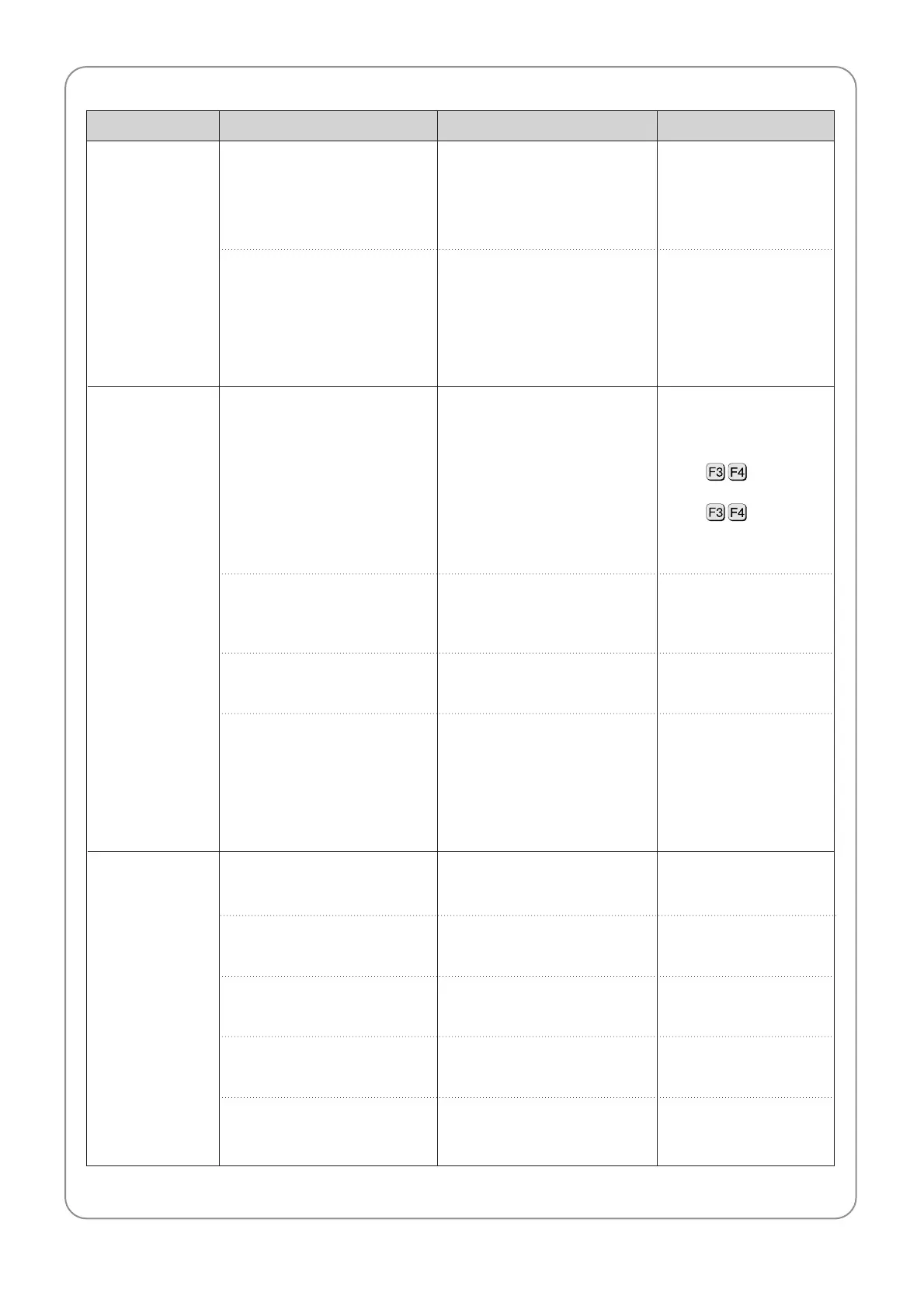

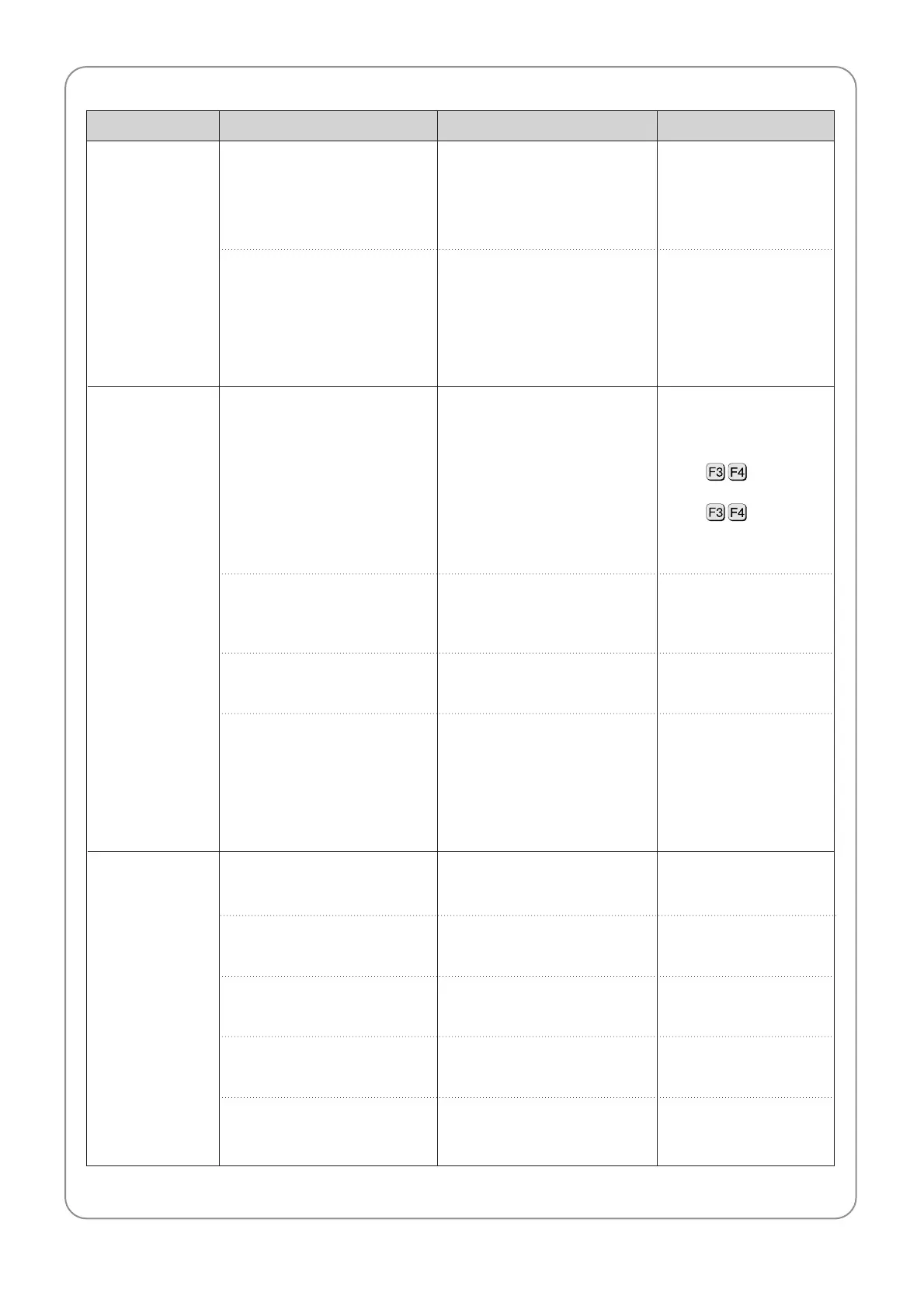

59

Poor Upper

Thread Detection

Defective Jump

Twisted

Embroidery

① Defective roller rotation

② Inappropriate contact of the

thread tension adjusting

plate to the connector and

the inappropriate operation

of the thread tension

adjusting plate

① Faulty SMPS for jump

② Faulty jump motor wiring

terminal and jump motor

③ Bad connector contact

④ Faulty switch on the thread

tension adjusting plate and

defective board

① Bad tape

② Inappropriate X-Y belt

tension

③ Foreign material stuck on

the X-Y rail

④ Bad X-Y driver

⑤ Heavy embroidery frame

■ Disassemble the body of the

thread sensing roller and

clean the thread sensing

roller and the bush bearing

■ Check the contact status of

the connector line on the

tension adjusting plate, and

replace the board

■ Replace the SMPS for jump

within the controller box

■ Check the wiring terminal

and replace the jump motor

■ Check the contact status of

the conductor

■ Replace the switch and the

board

■ Correct the tape

■ Adjust the tension

■ Clean the rail

■ Replace the driver

■ Slow down the speed of the

main shaft rotation

■ Check the rated

voltage of the fuse

1) For 3-phase

= 250V 15A

2) For 1-phase

= 250V 30A

Corrective Action and Check PointCause of TroubleType Remarks

Loading...

Loading...