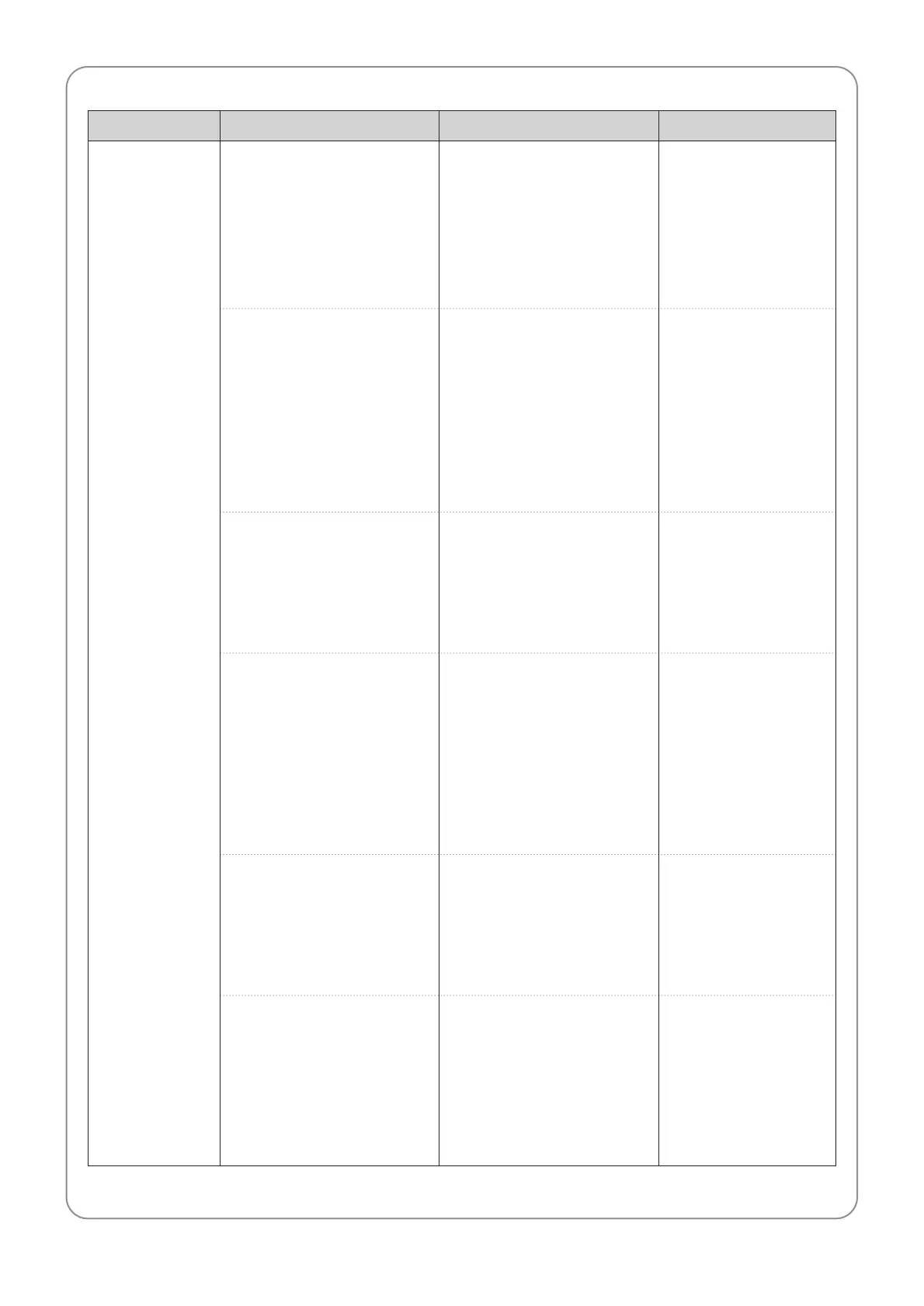

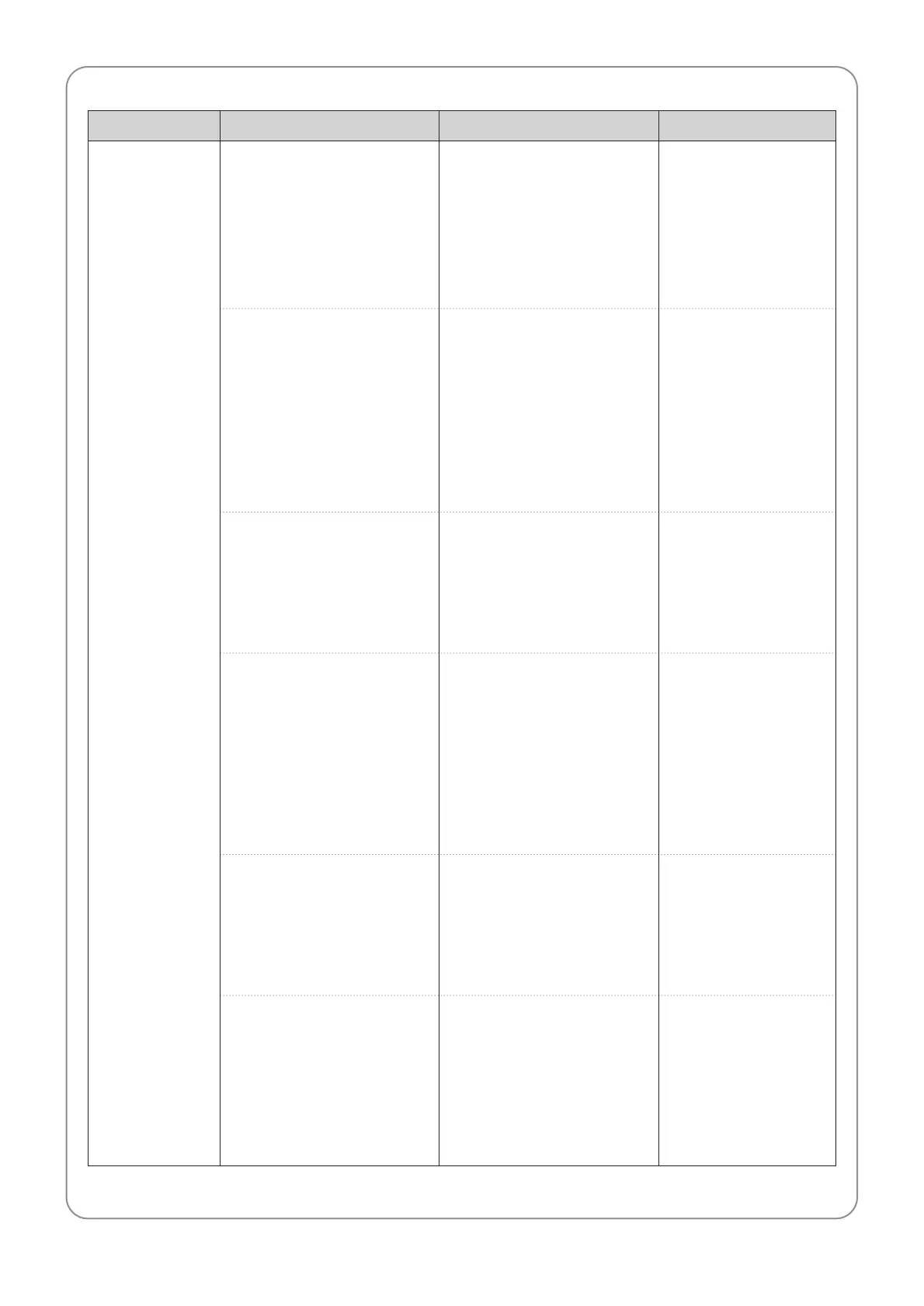

60

Thread Break ① Too small or close stitches

for the thread used

② Frequent thread breaks

around the same area of a

design

③ Inappropriate needle size

for the thread used

④ Needle damage (curved

needle, hole on the needle,

scratch on the groove,

abrasion or deformation of

the top of the needle)

⑤ Wrong placement of the

needle (needle height,

needle direction, etc.)

⑥ Needle contamination (i.e.

adhesives attached on the

needle resulting from

appliqué work)

■ Conduct punching again on

the design tape

■ Conduct punching again

after checking the design

status

■ Correct specific stitches by

using the operation panel

function

■ Replace the needle for

appropriate one in

consideration of the thread

used

■ Replace the needle

■ Reinstall the needle

■ Clean the needle and hook

or replace the needle

■ Check the design

status

■ Use the minimum

amount of adhesives

for appliqué work

Corrective Action and Check PointCause of TroubleType Remarks

Loading...

Loading...