10. FUEL SYSTEM

10-8

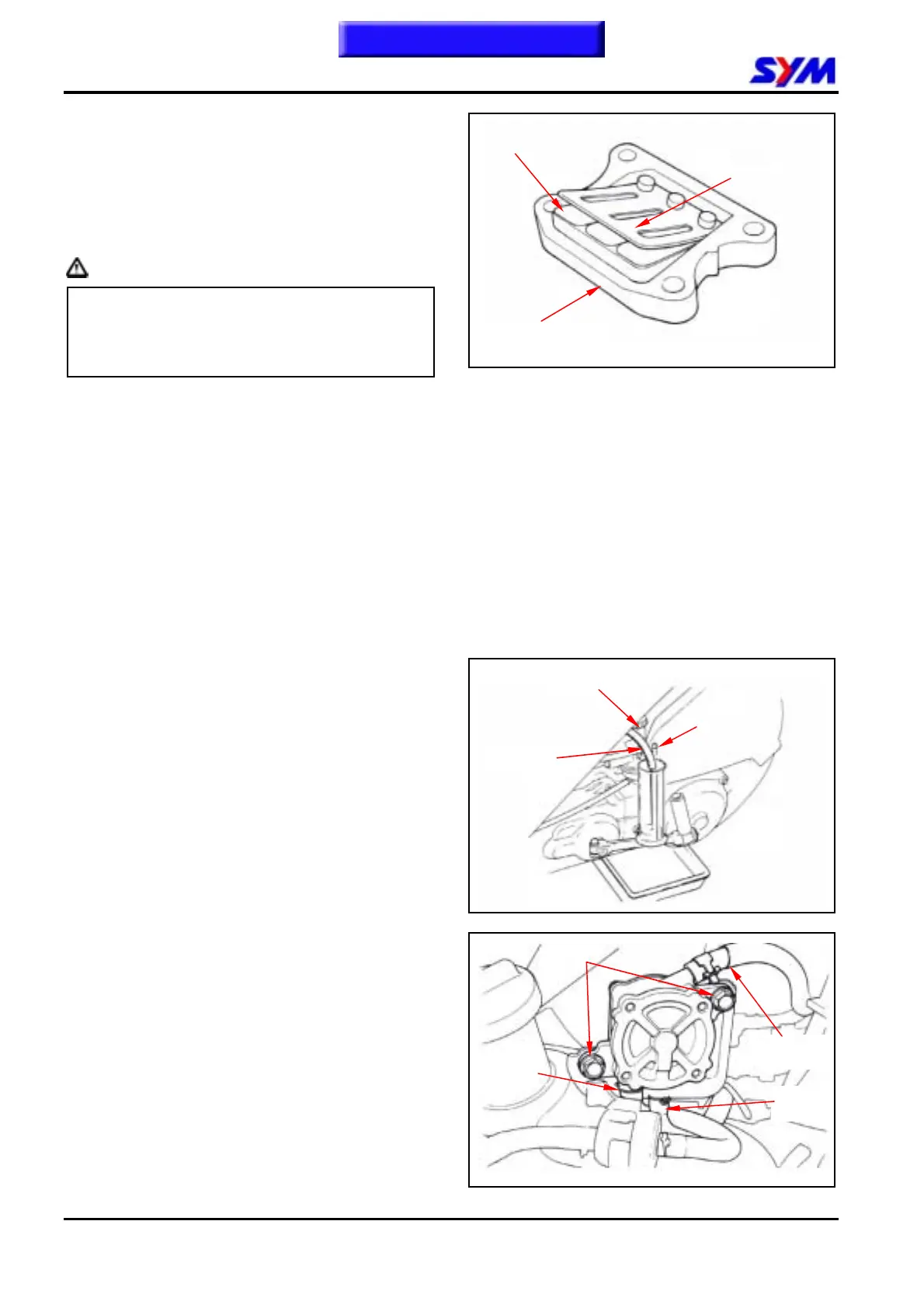

Inspection

Check the reed valve for damage and its reed

strength.

Check the reed valve seat for crack, damage

and the clearance between the seat and the

valve.

Replace reed valve if necessary.

Caution

Do not bend the reed valve stopper.

Otherwise, it will cause its strength insufficient

and rough engine running. If the reed valve

or its seat is damaged, replace with a set.

Installation

Install in the reverse order of removal

procedures.

Check for leaking after installed.

Fuel Pump

Inspection

Remove the body cover.

Warm up the engine and adjust idle speed.

Remove fuel hose from carburetor and then wait

for 5 minutes.

Measure the output of fuel pump. Its output

time is 10 seconds.

Output quantity: Min. 20 c.c.

If the output quantity is lower than 20 c.c., check

fuel hose, vacuum hose and fuel filter.

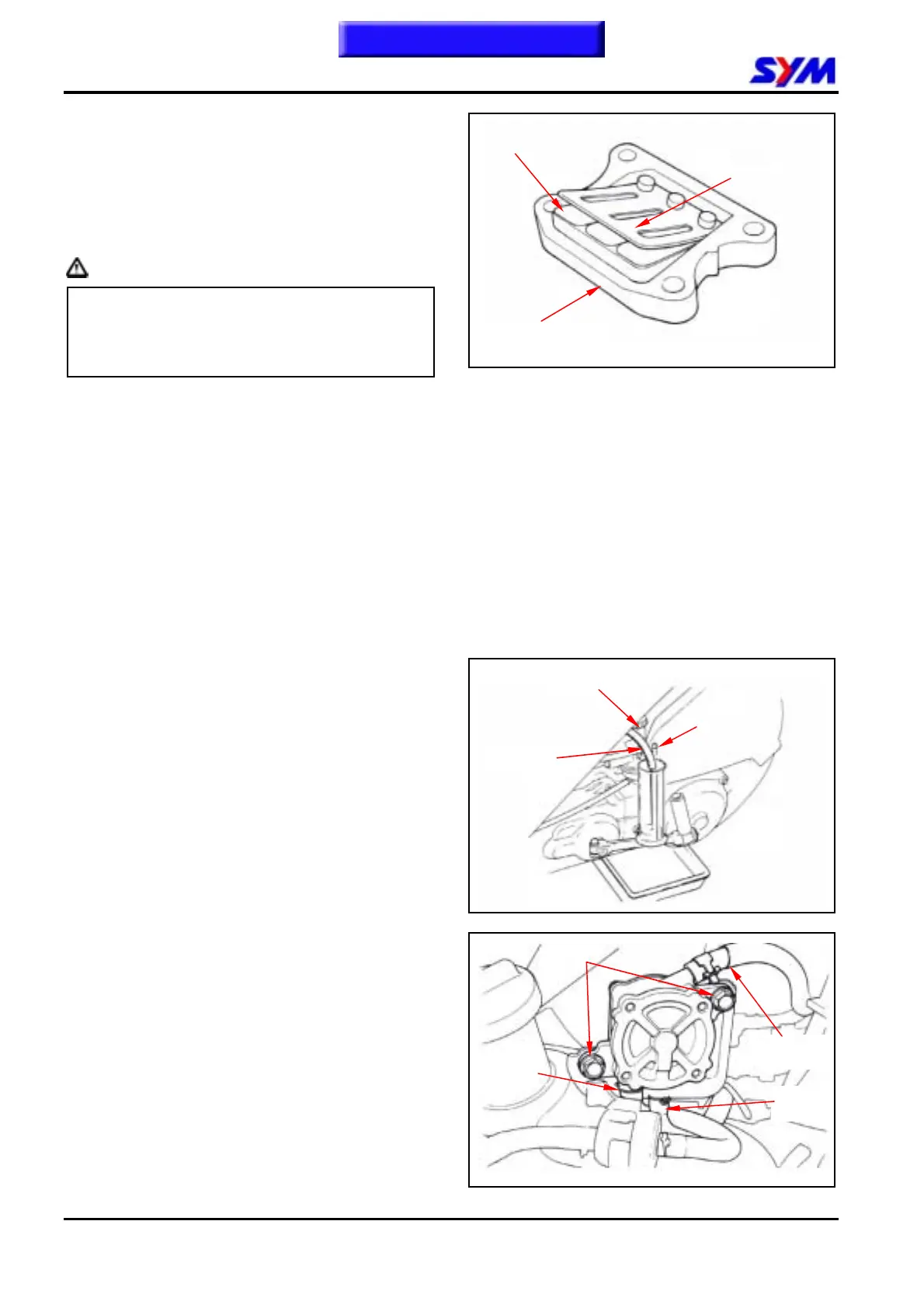

Removal/Installation

Remove floor plate.

Remove fuel inlet, outlet and vacuum hoses.

Remove 2 bolts and fuel pump.

Install the fuel pump in the reverse order of

removal procedures.

Carburetor

Fuel hose

Fuel inlet

hose

Fuel outlet

hose

Bolt

Vacuum

hose

Fuel hose

connector

Reed stopper

Reed valve

Reed valve seat

This chapter Contents

Loading...

Loading...