5

BREW & STEAM TANK SAFETY

Espresso machines have numerous potenal hazards, and it is of paramount importance to Synesso that

people servicing our machines take all necessary precauons to ensure their personal safety. When working

on the machine’s boilers (unless otherwise instructed in the direcons):

• Turn the machine o and shut o the incoming water supply.

• Depressurize the boilers as shown below.

When working on any electrical wiring (unless checking voltage or amperage readings or otherwise instruct-

ed in the direcons) ensure that the machine is switched o at the red on/o switch on the front panel and

the machine is unplugged.

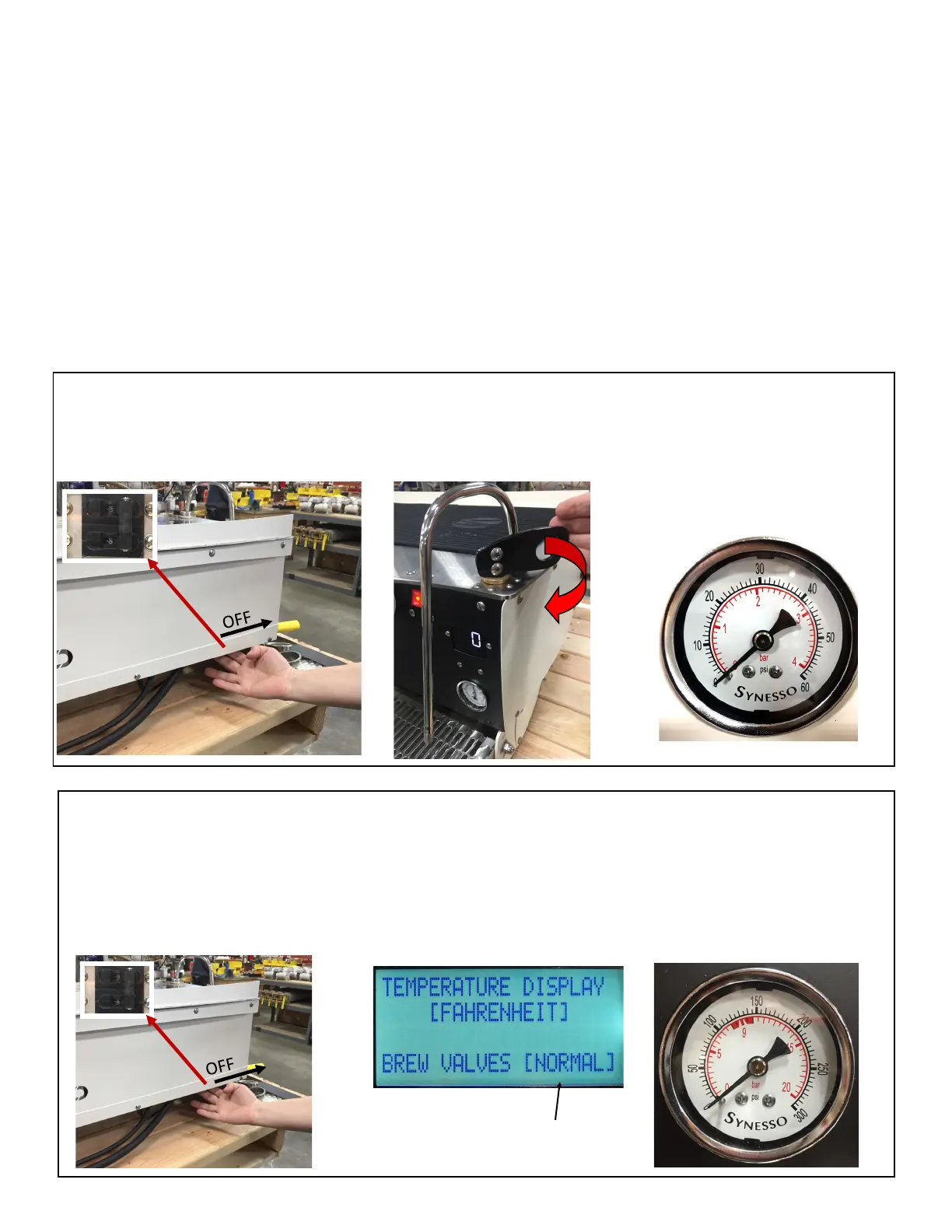

Depressurizing the Steam Tank:

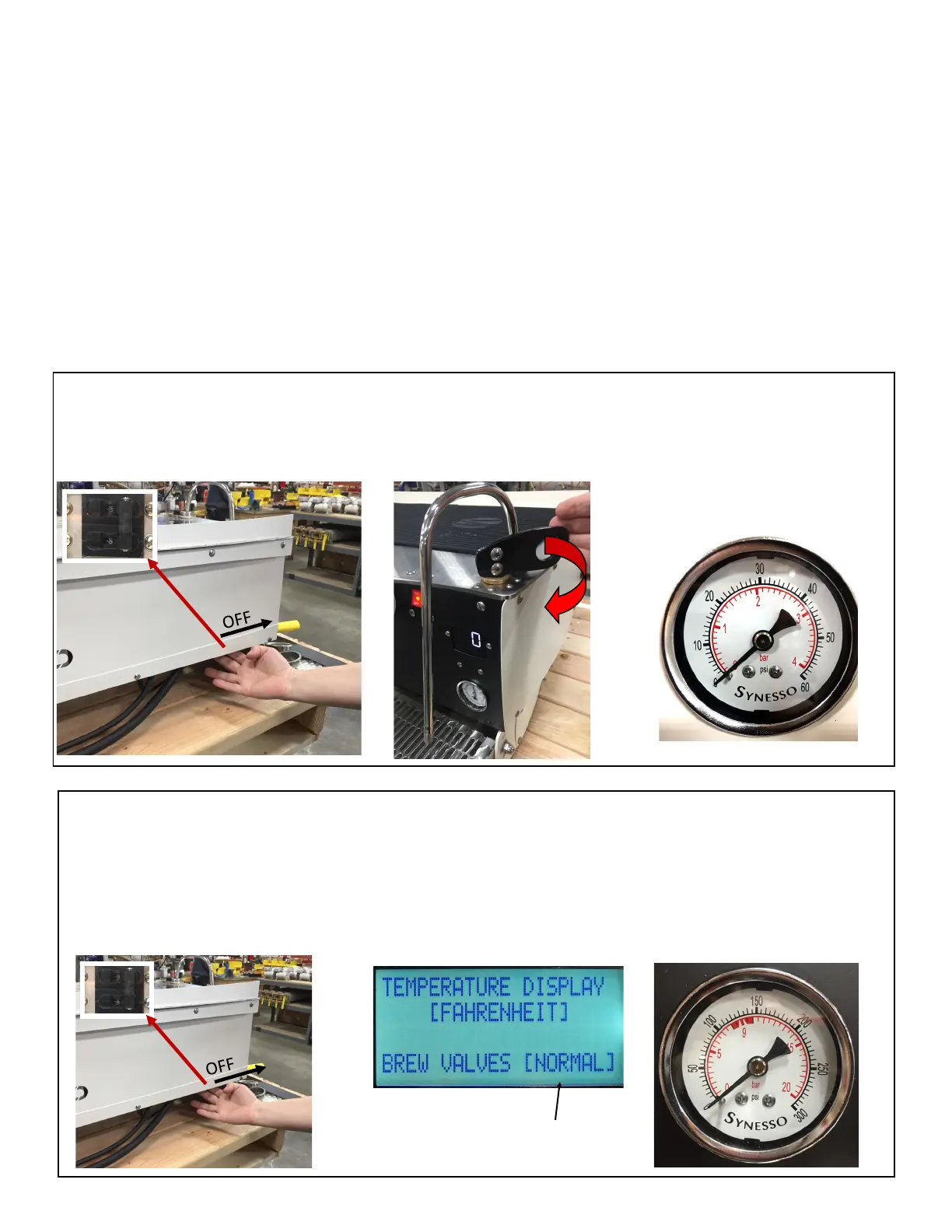

Depressurizing the Brew Tanks:

1. Turn o the element circuit

breaker located under the machine.

2. Also turn o the water supply to

the machine.

4. The brew tanks are depressur-

ized once the pressure gauge

reads zero. Note – the brew

gauges are rated at 0-300 psi

3. In the second level menu,

change the brew valves from

“Normal” to “ON” this will

bleed the pressure.

“NORMAL” to “ON”

1. Turn o the element circuit

breaker located under the machine

2. Open the steam valve by moving

the steam actuator lever forward

3. The steam tank is depres-

surized when the steam gauge

reads zero. Note: the steam

gauge is rated @ 0-60 psi

Loading...

Loading...