5

Doument in original language

GB

Safety Information

This installation instruction is a part of the product and must

therefore be stored so that it is always available. The manufacturer

of the system or installation is responsible for ensuring that the

installation and safety instructions are compliant with the applicable

regulations.

- Fans are certified in accordance with directive

94/9/EC(ATEX).Fan category BV3 and quality level G6.3 in

accordance with ISO 14694.

- Use fans within the areas stated on the type plate of the fan (for

example Ex e IIB T3).

- Fan fulfils the requirements for zone 1 but does not separate

zones

-The fans may be used in explosive environments for transport of

gases but not to transport hot flue gases.

- Transport of solid substances, proportions of solids or mixtures of

dust/air is prohibited.

- The fans are only intended for the transport of air or potentially

explosive atmospheres in zone 1 and zone 2.

- The transported air should not corrode the fan’s casing, impeller

or motor (aluminium and steel).

- Rust particles must not be found in the air stream.

- Resonance fluctuation may occur because of installed

components; this should be checked at commissioning.

- The fans must not be installed outdoors.

Installation, electrical connections and commissioning must only be

carried out by authorised installers in accordance with the

regulations and laws applicable to electrical installations in areas

with potentially explosive atmospheres.

- Installations carried out in accordance with EN 60079-14 are

considered to meet these requirements.

- Fans must be installed and protected against any possible causes

of sparks caused by foreign objects coming into contact with the

fan blades.

- If the fan is not installed in a duct system; a protection grille

should be installed.

- No moving parts should be accessible after installation (EN ISO

13857)

- Safety equipment, i.e. safety grilles, may not be dismounted,

bypassed or disconnected.

- Regular inspections and cleaning of deposits will prevent

imbalance in the impeller. Note that the panels that hold the fans

can be relatively heavy. Ensure that they are correctly reinstalled

after inspection/cleaning and tightened to the correct torques. See

the maintenance, service and repairs section.

- Before servicing, maintenance or repair the power must be

disconnected (main circuit breaker off) and the impeller must have

stopped.

- Warning! Cleaning with a damp cloth when the fan is

connected to voltage can cause an electric shock – danger to

life!

- The fans may have sharp edges and corners, which can cause

cutting injuries.

The fan’s type plate displays the fans data at rated voltage.

-Protective earth (PE) must be connected. All fans have an external

protective earth connection (positioned on the motor).

- Electrical connections must be carried out according to the wiring

diagram in the junction box, markings on the terminal blocks or on

cable.

- When controllable fans are regulated the current can increase

with regulated voltage. Note that the power may never exceed the

rated power stated on the type plate, see table 1.

- The max. permitted operating data stated on the type plates

applies to air with a density of 1.2 kg/m

3

(1.1 – 1.39 kg/m

3

)

- Min.flow on fans, see table 1!

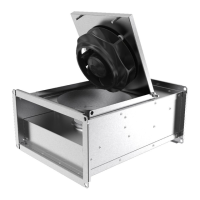

KTEX/DKEX:

Special conditions for safe use (1-5)

1. The fan’s rating plate displays the fan’s data at rated voltage. In

order for the fan’s permitted current and power consumption not to

be exceeded the fan may need to be pressurised with a minimum

counter pressure according to table 1.

2. PTC protective circuits in the motors must be connected to

monitoring apparatus certified according to Directive 94/9/EC that

isolates the motor from voltage supply immediately when activated.

3. When fans are installed in a duct system, the duct system must

meet enclosure classes IP20 at the inlet and IP10 at the outlet.

Components that contribute to the enclosure protection must be of

suitable material and durability.

4. Fans are only intended for fixed installation. The motors’

connection cable on KTEX is secured with cable ties in order to

guide the cable correctly in relation to the hinge on the hatch.

Attachment must be carried out so that the cable can still be

extended after fixing without the cable insulation being damaged.

5. Ambient temperature and temperature of transported air should

remain within the range – 20 to +40 °C. Fans must not be run at

flows below 200 m

3

/h at ambient temperature of 20°C. There is

otherwise a risk that the exhaust temperatures are higher than the

permitted ambient temperature.

- The motors are equipped with PTC triple protection resistors. No

more than two PTC resistor chains may be connected in series, this

can lead to undefined shut down.

- Max. test voltage for PTC resistance: 2.5 V.

- KTEX and DKEX type fans must be installed with an Ex certified

temperature monitoring unit. Checks and maintenance of the

temperature monitoring unit must be carried out according to

instructions and to a time interval that is given in the temperature

monitoring unit certificate and user instructions.

- Use of electronic or transformer based control devices is

permitted.

- Speed control using frequency inverters is not permitted.

- Current dependent protection is not permitted and must not be

used as secondary protection either.

- Motors are supplied with open drain holes.

Ex 140/180:

-

Fans must be equipped with a circuit breaker that can be

adjusted so that it protects the motor from overloading and

switches off within 15 seconds if the impeller is blocked.

- When determining the cut-out time of the motor protection, there

should be a curve that displays the motor protection cut-out time as

a function of the start current status (IA/IN) for 2.9 < IA/IN < 8 with

an ambient temperature of 20°C. The motor protection cut-out time

must not deviate more than 20 % from the cut-out curve.

- The current/power of the fans must not exceed the rated

current/rated power at rated voltage stated on the rating plate.

- The current/output values are given in table 1, by increasing the

statistical counter pressure the fan can be choked to a lower

current/output.

- The fans must not be speed controlled.

Transportation and storage

-All fans are packaged at the factory to withstand normal transport

handling.

- When handling the goods, use suitable lifting equipment in order

to avoid damage to fans and personnel.

- Avoid blows and shock loads.

- Store the fans in a dry place, protected from weather and dirt until

final installation.

- Avoid excessive storage periods (we recommend a maximum of

one year).

- Before installing the fan, check motor bearings for any noise

(carefully spin the fan by hand).

- Note! Do not lift the fans by the mains cable, connection box,

impeller or inlet cone.

Installation

Always refer to the Safety information above before

installation.

Fans are only intended for fixed installation. The installation

requires that a classification of the hazardous area has been made

according to applicable regulations (in Sweden SRVFS 2004:7

applies) and classification standards (within the EU EN 60079-10

Loading...

Loading...