22 Maintenance / remedying of faults

WARNING

Hazard from electrical voltage

› Remedying of faults and maintenance only by a trained electrician or trained and instructed qualied personnel.

› Pay attention to the industrial protection regulations in troubleshooting.

› Pay attention to the 5 rules of electrical engineering:

– clear (all-pole separation of an electrical system from live parts)

– secure against switching on again

– establish freedom from voltage

– earth and short-circuit

– cover or fence off neighbouring live parts.

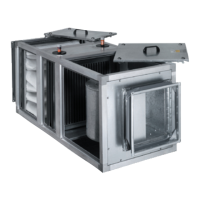

22.1 Defects and remedying

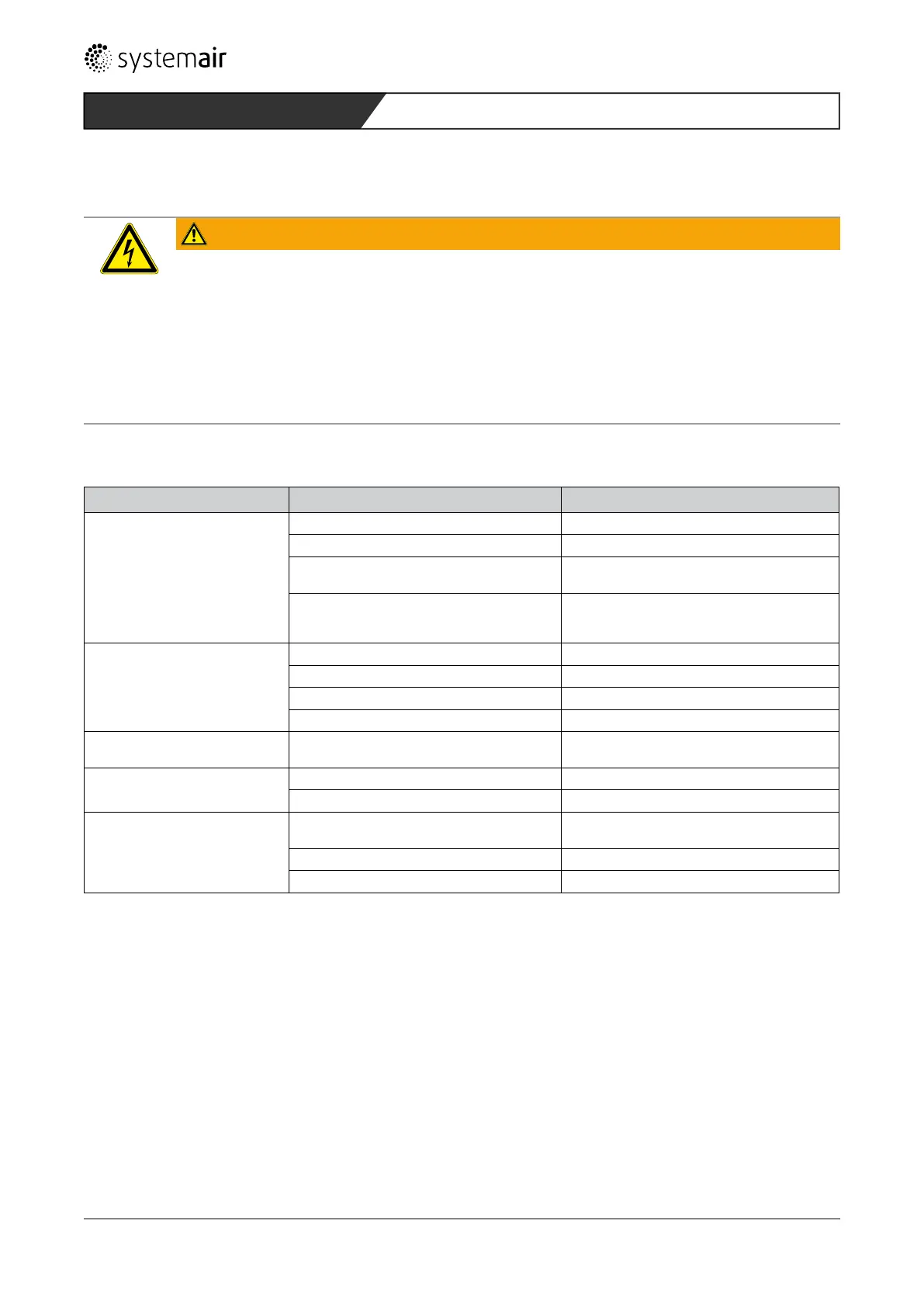

Disturbance Possible causes Remedy

Multibox runs loud Rotor out-of-balance Re-balance by specialist company

Adhesions to rotor Clean carefully, re-balance if necessary

Material decomposition on rotor due to exces-

sive tem-perature

Contact manufacturer

Deformation of rotor due to excessive tem-

perature

Contact manufacturer,

install new rotor,

check bearings

Output of Multibox too low Wrong direction of rotation of rotor Change direction of rotation

Loss of pressure in lines too high Different line guidance

Throttle organs not or only partly open Check opening positions on site

Suction or pressure paths blocked Remove obstacles

Grinding sounds in operation or

start of the Multibox

Suction line installed twisted Loosen suction line and re-align.

Thermo-contacts have reacted Capacitor not or not correctly connected Connect capacitor

Motor blocked Contact the manufacturer

Multibox does not reach no-minal

speed

Electrical switching devices set wrongly Check and possibly reset setting of switching

device

Motor coil defective Contact manufacturer

Drive motor has been de-signed wrongly Contact manufacturer for check of start torque

Table 7: Troubleshooting

47

Multibox MUB - V 1.0

Maintenance / remedying of faults

Loading...

Loading...