English

This equipment contains uorinated gas with greenhouse gas effects covered by the Kyoto

agreement.

Caution

SysAqua units use the R410A uoro-carbonated uid, belonging to group 2 as dened in directive

97/23/CE. Considering the maximum operating pressure of these units (42 bar g), they integrate

category 2 (or lower) components as dened in directive 97/23/CE.

Caution

10 SysAqua

8.2. REFRIGERATION SPECIFICATIONS

8.2.1. REFRIGERANT CIRCUIT DIAGRAM

SEE APPENDIX

8.2.2. REFRIGERANT CHARGE

The type and quantity of refrigerating uid per circuit are indicated on the product plate.

The installer and end user will get informed on local environmental regulations for the installation, operation

and disposal of the equipment ; more particularly, for the collection of substances hazardous for the

environment (refrigerating uid, oil, antifreeze, etc.). A refrigerating uid, whatever it is, must not be vented.

Refrigerating uids must be handled by skilled personnel.

8.2.3. FLUOROCARBON GAS REGULATIONS

The EC No. 842/2006 regulation covering uorinated greenhouse gases requires of refrigeration equipment

operators to comply with the following ve obligations:

Non-compliance with one of these obligations constitutes an offense and can result in nancial

penalties.

Furthermore, compliance of the equipment with the uorinated gases regulation must be proven to

the insurance company.

Caution

1. Installation, servicing, maintenance as well as checking the sealing must be carried out by qualied

personnel.

2. The uorinated gas must be recovered during servicing and maintenance as well as the end of the

installation.

3. All the necessary measures must be taken to prevent the leakage of uorinated gases and any leaks

must be repaired as rapidly as possible.

4. Regular checks on any leaks must be performed according to the following conditions:

load6 kg - at least once every 12 months

load30 kg - at least once every 6 months

5. A document grouping a description of all the operations carried out on the cooling circuit must be

drafted and conserved.

8.3. ELECTRIC SPECIFICATIONS

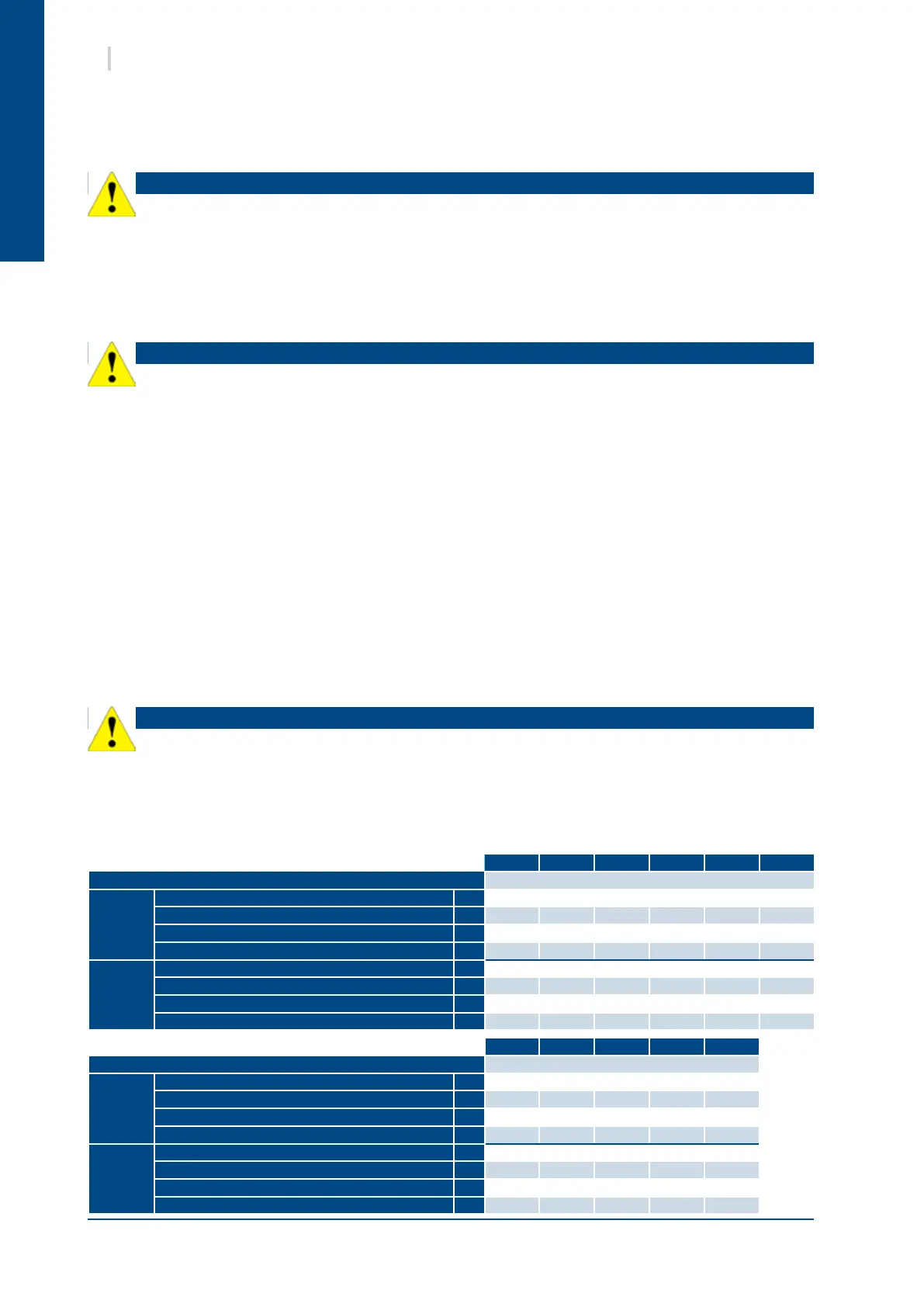

8.3.1. SYSAQUA WITH STANDARD FAN

25 30 35 40 45 55

Power supply 3N ~400 V - 50 Hz

Without

pump

Maximum current A

22.5 24.5 32 34 41 45

Fuse rating aM A

25 25 32 40 50 50

Total starting current (without soft starter) A

64 77 119 120 134 141

Total starting current (with soft starter) A

35 49 53 54 67 74

Standard

pump

Maximum current A

24.5 26.5 34.5 36.5 43.5 50

Fuse rating aM A

25 32 40 40 50 50

Total starting current (without softstarter) A

66 79 121 122 137 146

Total starting current (with softstarter) A

37 51 56 57 69 79

65 75 90 105 125

Power supply 3N ~400 V - 50 Hz

Without

pump

Maximum current A

59.5 64.5 79.5 87.5 103.5

Fuse rating aM A

63 80 80 100 125

Total starting current (without soft starter) A

202 207 266 313 351

Total starting current (with soft starter) A

101 106 129 147 184

Standard

pump

Maximum current A

64.5 69.5 84.5 92.5 108.5

Fuse rating aM A

80 80 100 100 125

Total starting current (without softstarter) A

207 212 271 318 356

Total starting current (with softstarter) A

106 111 134 152 189

Loading...

Loading...