35

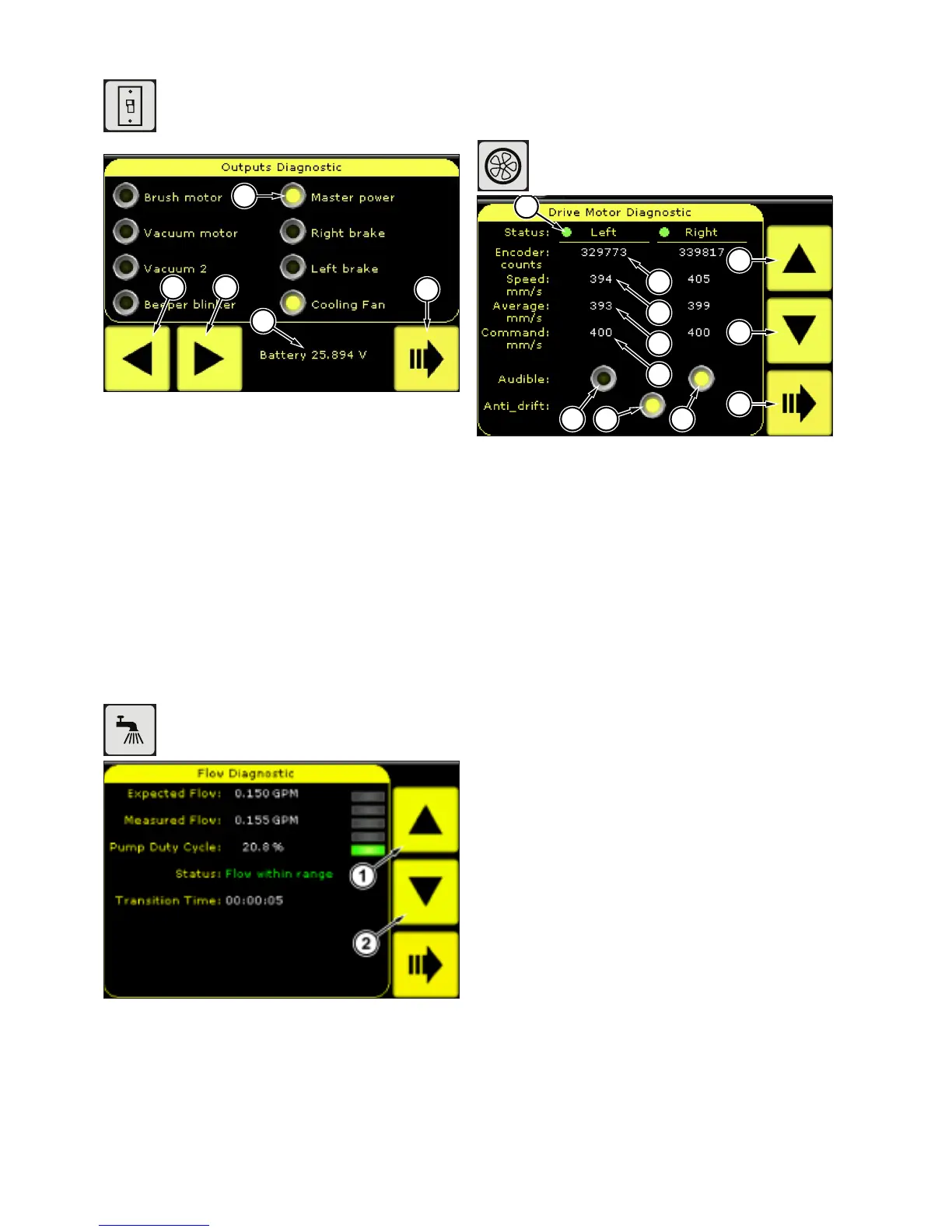

41. Outputs Diagnostic

The outputs diagnostic is used to aid in

system troubleshoot by allowing privileged

operators to turn on specic machine

devices and verify their operation.

5

4

2 3

1

Figure: 64

1 Output on/off button

2 Cycle backward through output screens

3 Cycle forward through output screens

4 Battery voltage display

5 Return to diagnostics main screen

Cycle through the output screens by pressing the next (3)and

previous (2) keys. Press the desired output (1) to cycle on or

off.

The current battery voltage (4) is displayed during the

diagnostic test.

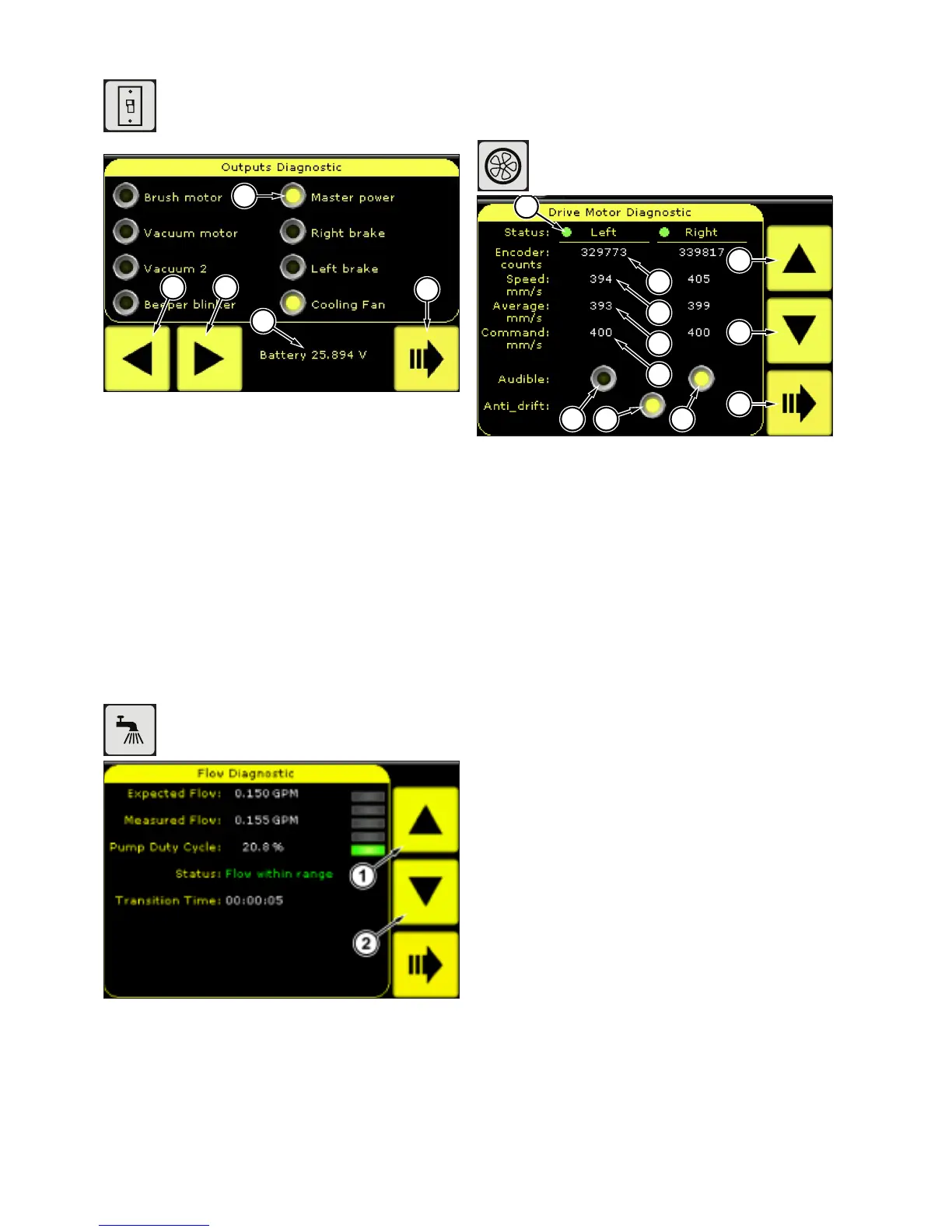

42. Flow Diagnostic

The ow diagnostic allows for testing and

troubleshooting of the pumping system.

Figure: 65

Pressing the up (1) arrow will increase the system ow rate

and start a priming cycle. The cycle may be terminated by

pressing the down arrow (2).

Priming may take up to two minutes. A priming failure may

indicate an air leak in the plumbing, check for loose canisters

or missing o-rings and restart the diagnostic.

Once priming is complete, the measured ow rate should be

within 0.03 gpm (0.11 lpm) of the expected ow rate.

43. Drive Motor Diagnostic

The drive motor diagnostic utility provides

information used by a trained service

technician to calibrate the drive motors.

2

3

4

5

6 67

8

9

10

Figure: 66

1 Amplier status indicator

2 Encoder counts

3 Speed mm/s

4 Average mm/s

5 Command mm/s

6 Audible alert

7 Anti-drift

8 Step the command speedup

9 Step the command speed down

10 Return to diagnostics main screen

The diagnostic can be used to verify the status of the drive

ampliers by checking the Status lights (1). Green lights

indicate the drive amplier is operational, a red light indicates

a fault.

Loading...

Loading...