5-4

USER INTERFACE

Model C722

User Interface

5

Optional Feed Tube (Back-up Option)

If the air/mix pump has become inoperable because of a

missing or damaged part, the operator can temporarily

operate the unit using the feed tube. The product ejection

rate will be slower when the feed tube is used instead of

the air/mix pump.

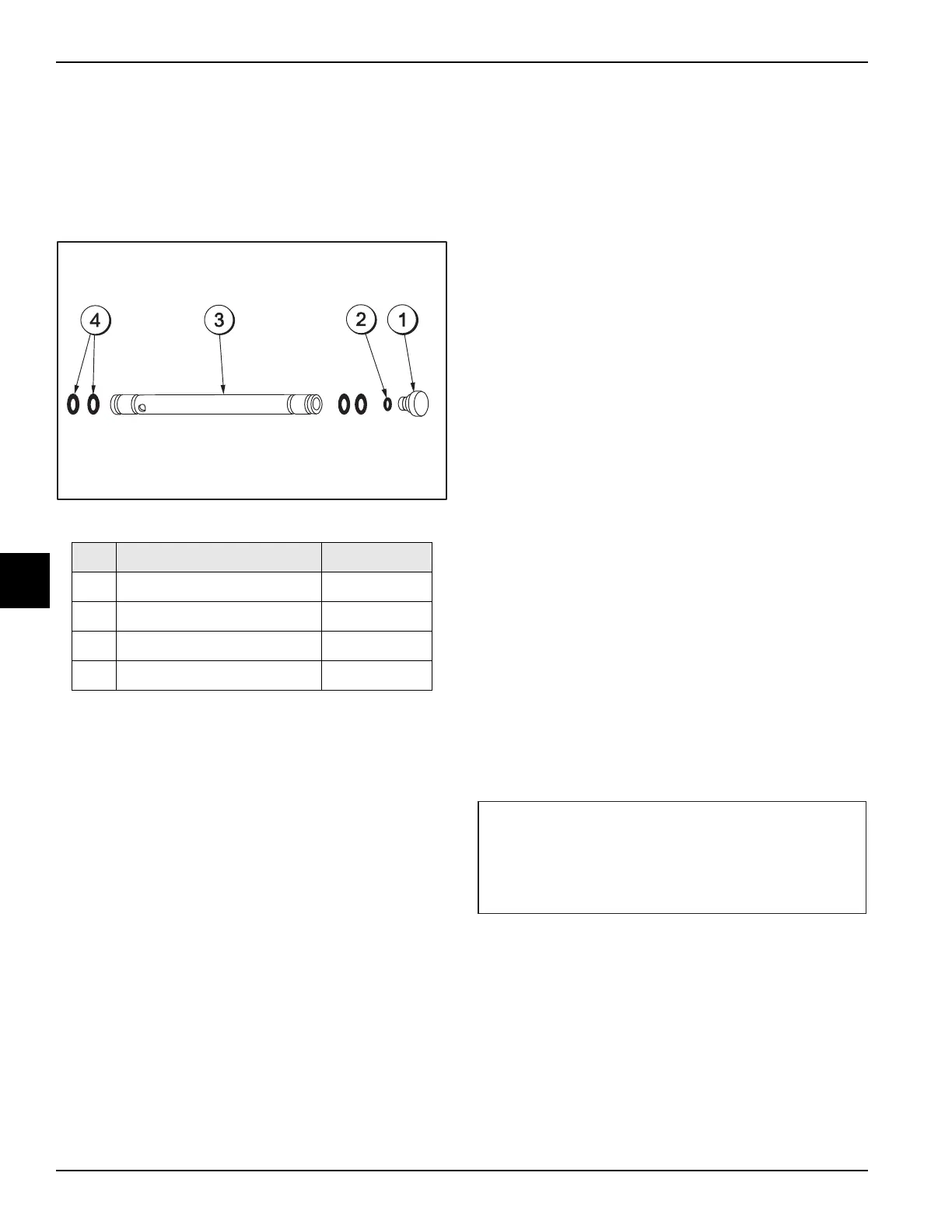

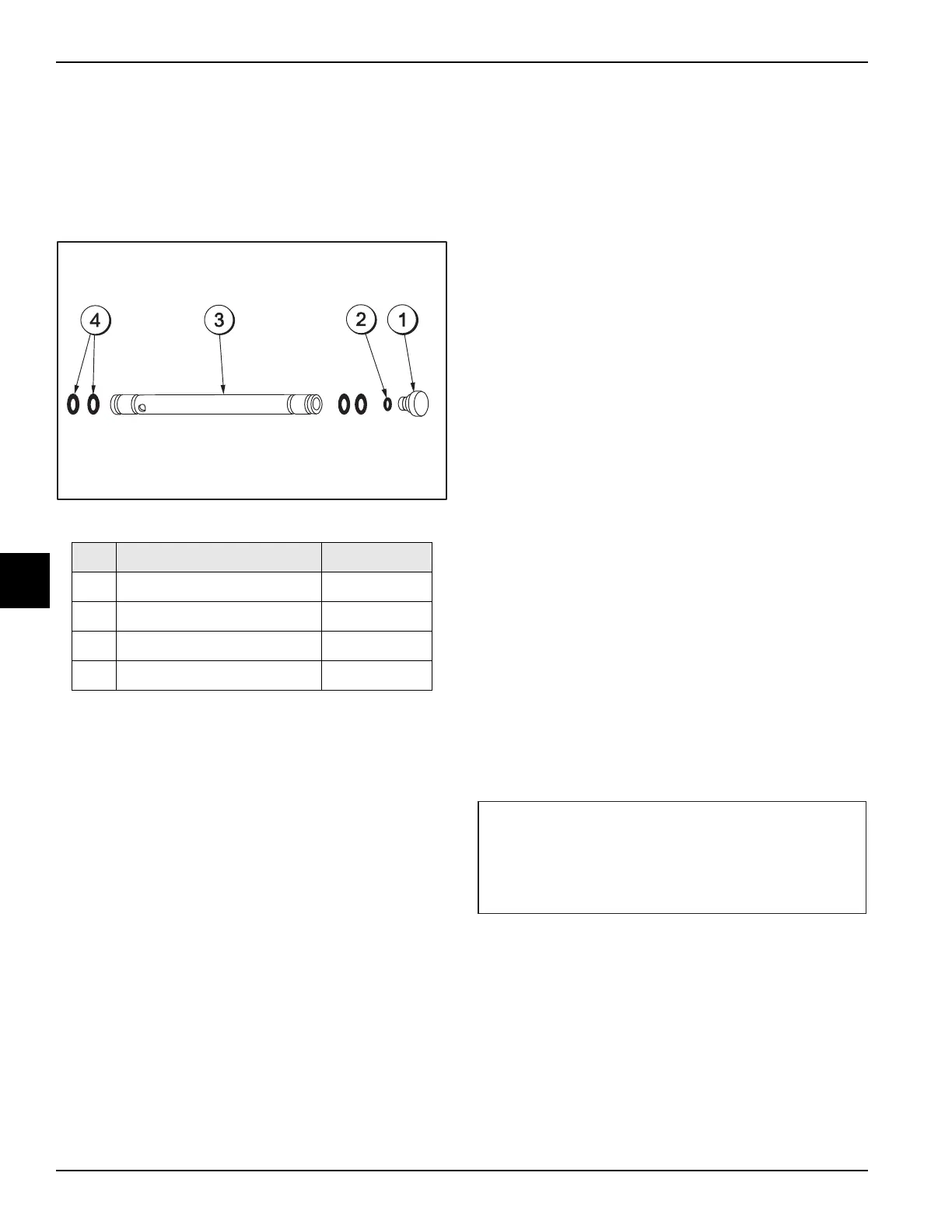

Figure 5-3

The feed tube serves two purposes. One end of the tube

has a hole and the other end does not.

1. Normal Operation

During normal operation, the end of the feed tube

with the hole is placed into the mix inlet hole. Every

time the draw handle is raised, new mix and air from

the hopper flow into the freezing cylinder. This keeps

the freezing cylinder properly loaded and maintains

overrun.

2. Long “No Sale” Periods

During long “No Sale” periods, the unit can be placed

into the Standby mode. This maintains product

temperatures below 40°F (4.4°C) in both the hopper

and the freezing cylinder, and helps prevent over-

beating and product breakdown.

To place the unit into the Standby mode, press the

STANDBY key. Remove the air orifice. Lubricate the

o-rings located on the end of the feed tube without the

hole. Place that end of the tube into the mix inlet hole.

This will prevent any mix from entering the freezing

cylinder.

Note: The air orifice is used to meter a certain amount

of air into the freezing cylinder. The air orifice maintains

overrun and allows enough mix to enter the freezing

cylinder after a draw.

Operating Screen Descriptions

The LCD located in the center of the control panel is

normally blank during the daily operation of the machine.

The display is activated when the SEL symbol or the

Manager's Menu is selected. The display screen will also

alert the operator of specific faults detected by the

control.

Power Up

When the machine is powered, the control system will

initialize to perform a system check. The screen will

display INITIALIZING. There are four types of data the

system will check: LANGUAGE, SYSTEM DATA,

CONFIG DATA, and LOCKOUT DATA.

If the system detects corrupt data during “initializing.....,”

the detected faults will be displayed for acknowledgment

after the SAFETY TIMEOUT display, if the power switch

is on. The faults may be CORRUPTED LANGUAGE,

CONFIG CRC ERR, SYSTEM CRC ERR, FAULT

HISTORY, LOCKOUT CRC ERR, or POWER FAILURE.

Once the system has initialized, the number of days

remaining before the next required brush-cleaning is

indicated on the control panel and the SAFETY

TIMEOUT screen is displayed with the alarm turned on.

The SAFETY TIMEOUT screen will be displayed with the

alarm on for 60 seconds, or until any control symbol is

selected.

Item Description Part No.

1 Orifice 022465-100

2 O-ring-3/8 OD X .070 W 016137

3 Tube A.-Feed-SS 5/32 Hole X29429-2

4 O-ring-.643 OD X .077 W 018572

SAFETY TIMEOUT

ANY KEY ABORTS

Loading...

Loading...