6-8

OPERATING PROCEDURES

Model C722

Operating Procedures

6

12. Lay the pump assembly, pump clip, cotter pin, mix

feed tube, and the agitator in the bottom of the mix

hopper for sanitizing.

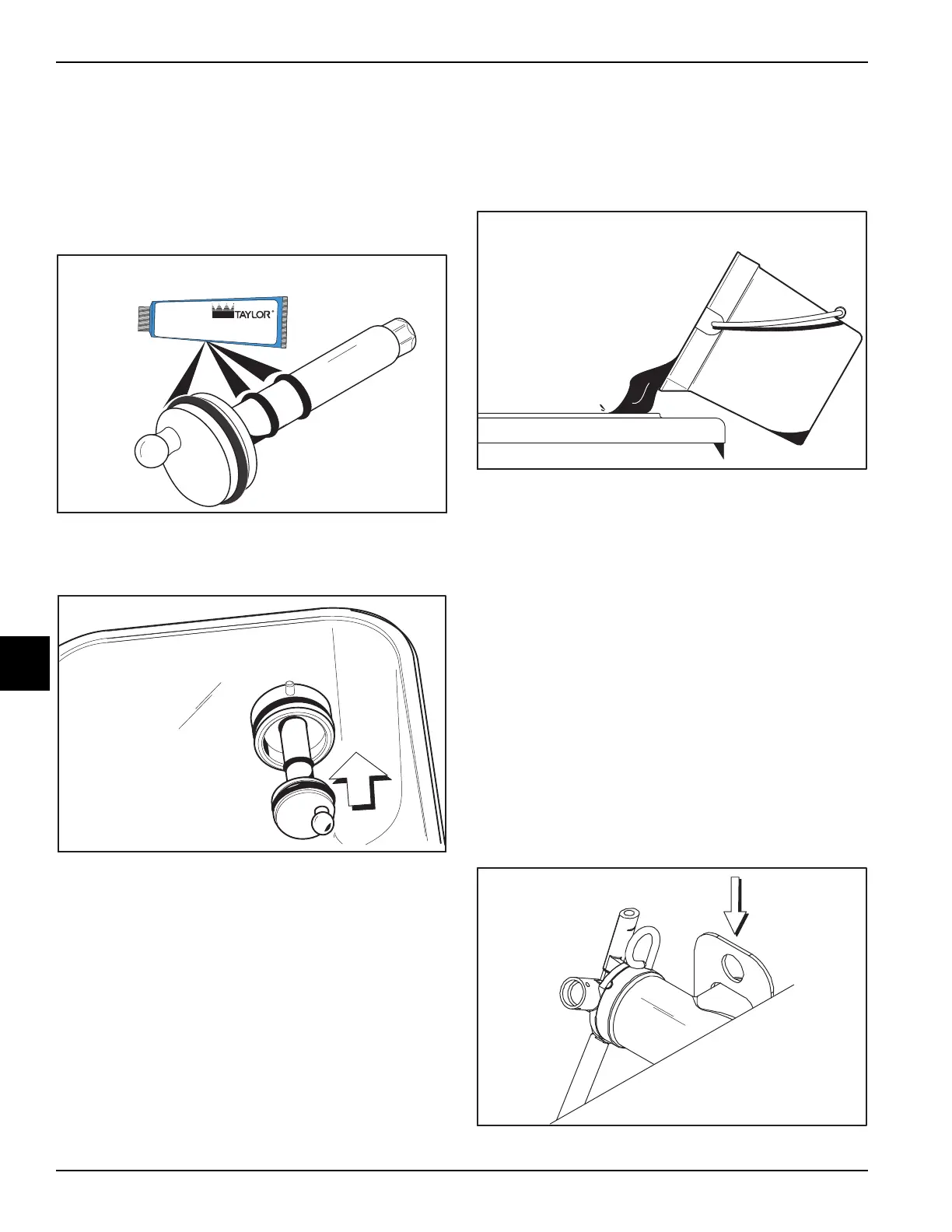

13. Slide the large black O-ring and the two smaller black

O-rings into the grooves on the driveshaft.

Thoroughly lubricate the O-rings and shaft. Do not

lubricate the hex end of the shaft.

Figure 6-32

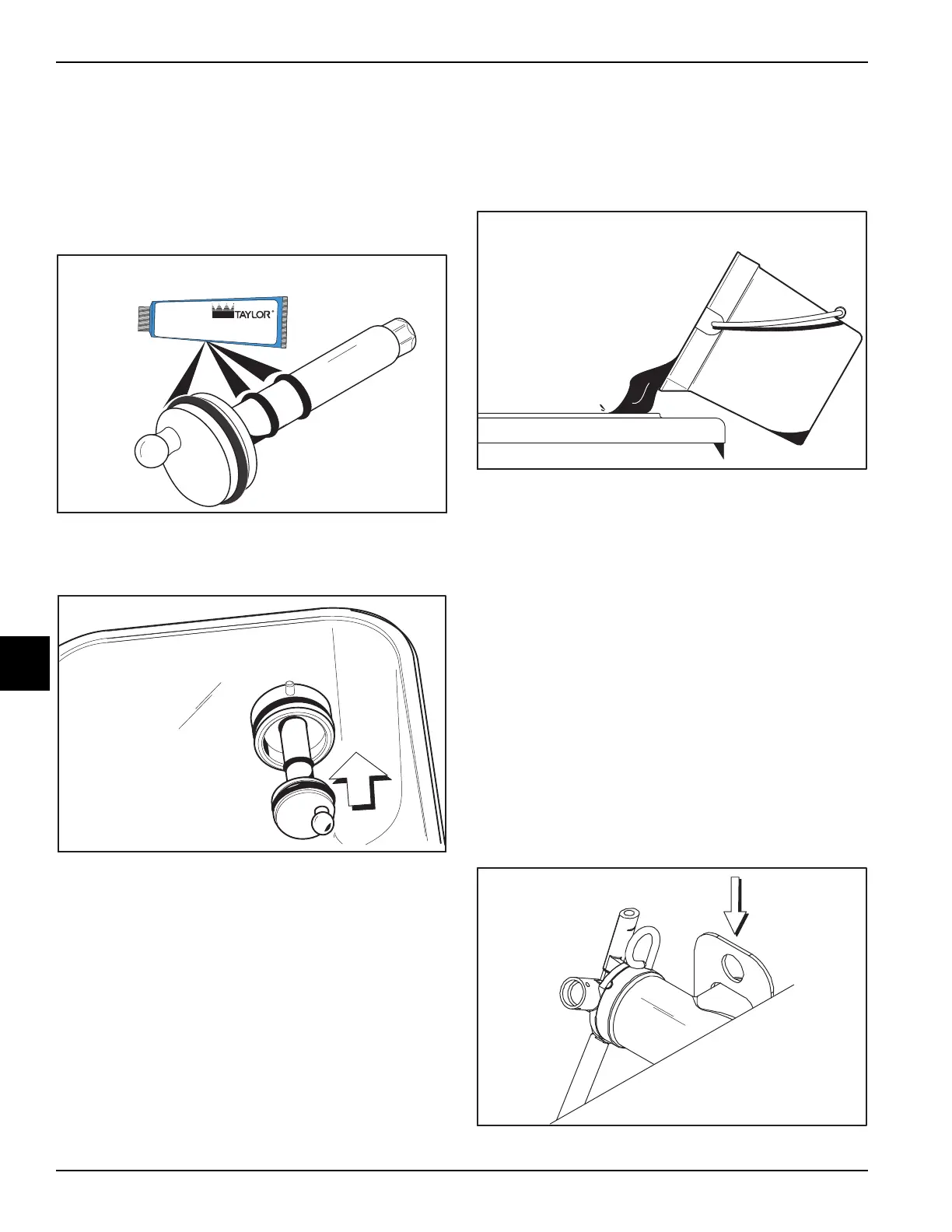

14. Install the hex end of the driveshaft into the drive hub

at the rear wall of the mix hopper.

Figure 6-33

Note: For ease in installing the pump, position the

ball crank of the driveshaft in the three o'clock

position.

Repeat steps 1 through 14 for the other side of the

machine.

Sanitizing

1. Prepare a pail of cleaning/sanitizing solution with an

active chlorine concentrate of 100 ppm–200 ppm

(parts per million).

Important! Use warm water and follow the

manufacturer's specifications.

2. Pour sanitizing solution over all the parts in the

bottom of the mix hopper and allow it to flow into the

freezing cylinder.

Figure 6-34

Note: You have just sanitized the mix hopper and

parts. Therefore, make sure your hands are clean

and sanitized before proceeding with these

instructions.

3. While the solution is flowing into the freezing cylinder,

take particular care to brush-clean the mix-level

sensing probe, mix hopper, mix inlet hole, air/mix

pump, pump clip, mix feed tube, cotter pin, and

agitator.

4. Install the pump assembly at the rear of the mix

hopper. To position the pump on the drive hub, align

the drive hole in the piston with the drive crank of the

driveshaft. Secure the pump in place by slipping the

pump clip over the collar of the pump, making sure

the clip fits into the grooves in the collar. (

See

Figure 6-35.)

Figure 6-35

15009

Apply the appropriate

Taylor approved food safe lubricant.

Loading...

Loading...