5-66

5-6-4 Brake Mode

z Brake function for servo motor and the external mechanical brake if it is used can be set

according to the table below. Set the brake mode as required for Servo off, Emergency

Stop and CCW/CW rotation inhibit functions.

Parameter Name Setting Description

Control

Mode

Dynamic Brake Mechanical Brake

0 Disable Disable

1 Disable Enable

2

Reserved

Cn008

Brake

Modes

3

Reserved

ALL

Note!

When the CCW/CW Drive Inhibit occur, the Cn009 has the higher priority than Cn008.

Example:

If Cn008 is set to 0 or 1 which means (no Dynamic Brake).

BUT Cn009= 1 (with Dynamic Brake), then the dynamic brake will be effective( enabled).

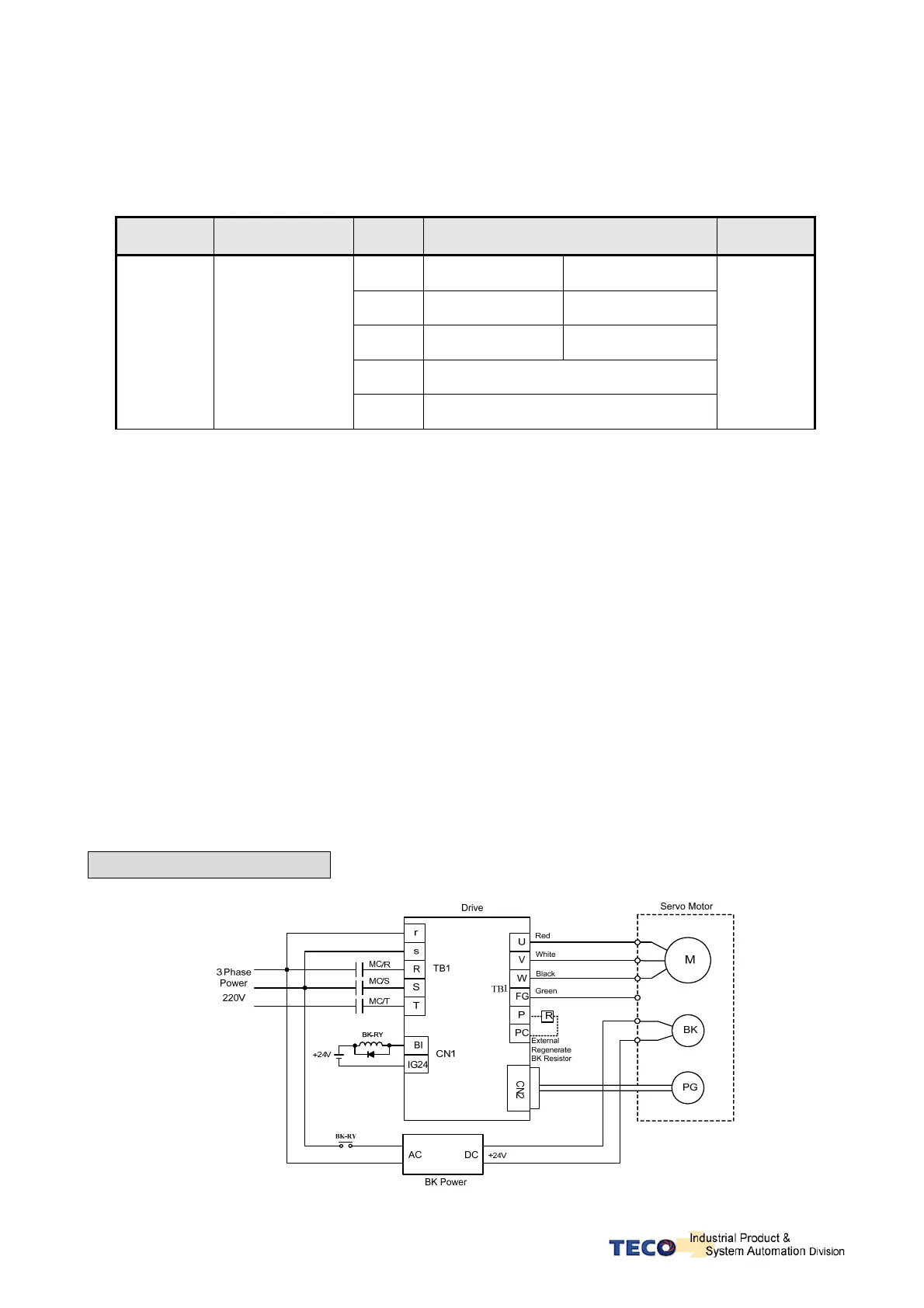

5-6-5 Timing Diagram of Mechanical Brake

z In applications with vertical loading, if the power is turned off, to prevent the load from

falling due to gravity, a servo motor with electro-mechanical brake can be used.

z This servo drive provides a brake output (BI) which can be used for controlling the

external brake.

z Timing of brake output signal can be set by parameter Cn003 (Output Time for

electro-mechanical Brake).

Typical Circuit Diagram