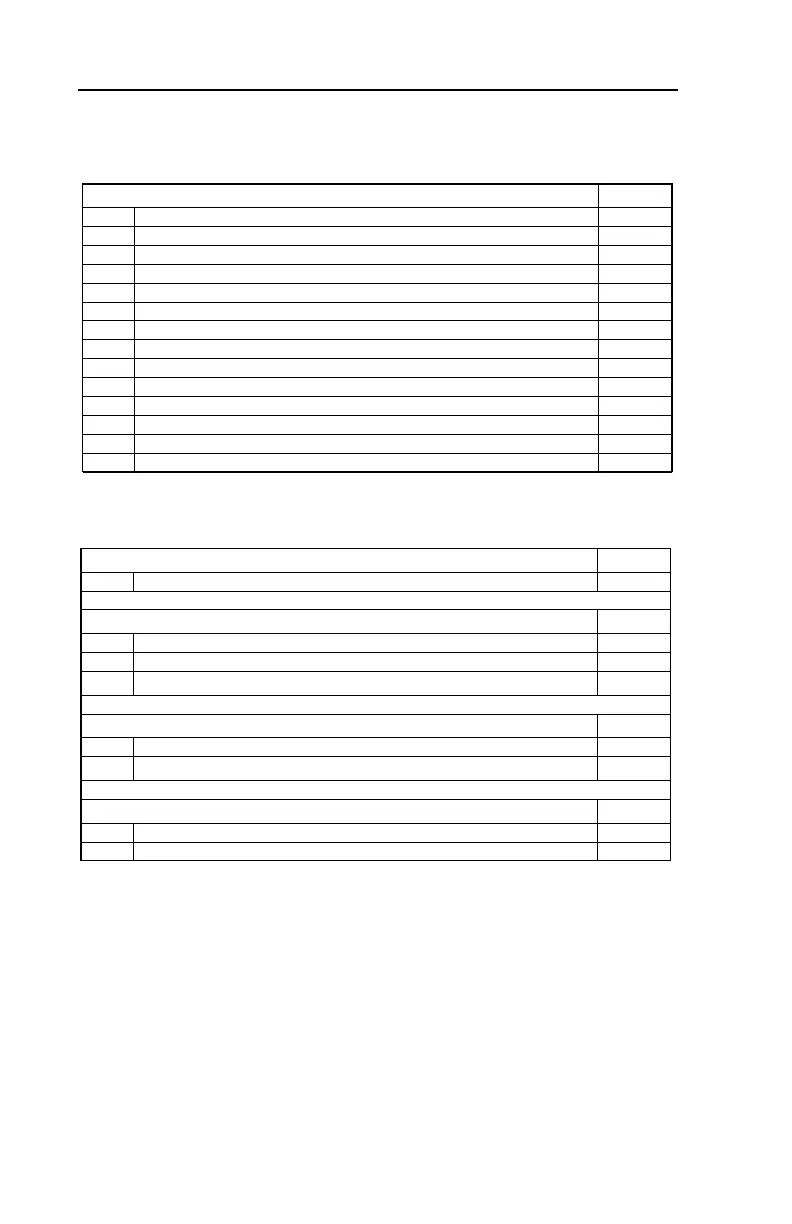

7.3 Maintenance Intervals

7.3-1 Daily Maintenance Tasks

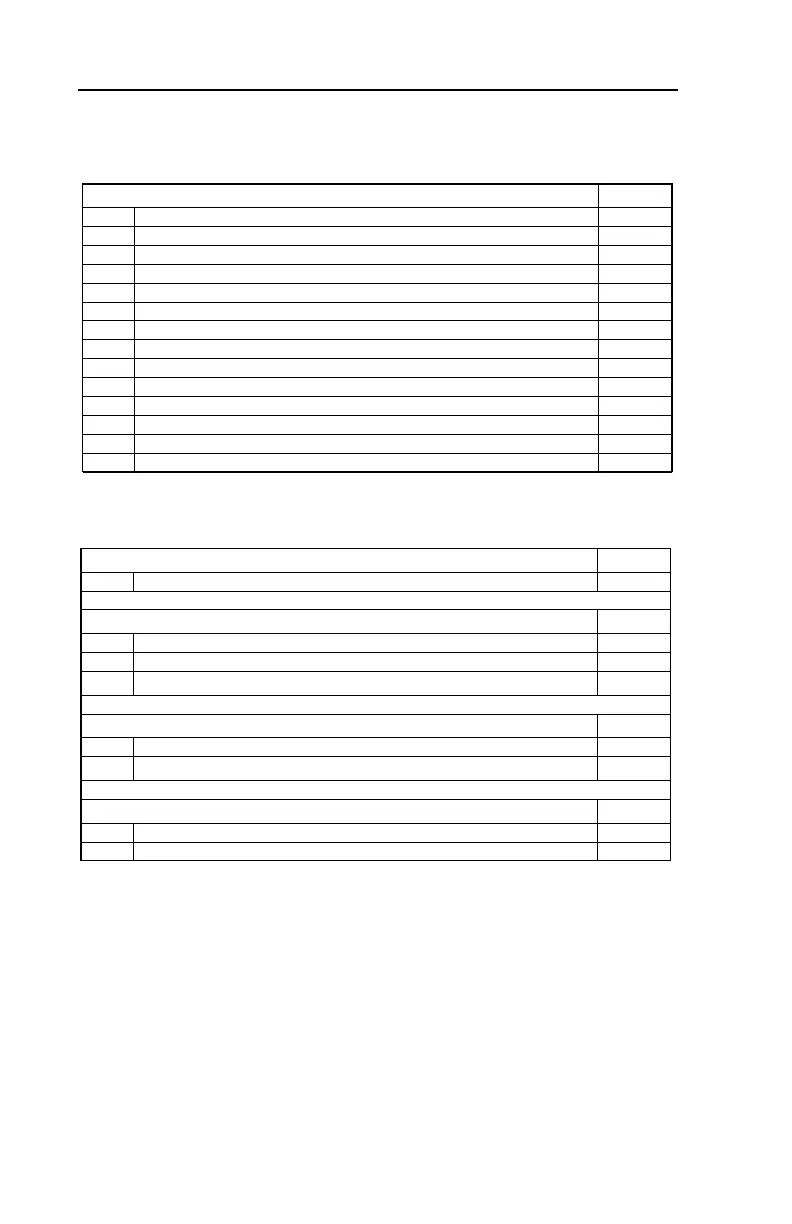

7.3-2 50-1000 hour Tasks

7 MAINTENANCE

64

Page

1 Check hydraulic oil level (figure 7.7-3, p-68) 68

2 Check engine oil level 66

3 Check fuel level (gauge on instrument panel) 37

4 Check fan belt tension / condition 69

5 Check track tension / condition 71

6 Check for proper control operation 40

7 Chech safety circuit for proper operation 47

8 Check for proper switch and lighting operation 37

9 Inspect air cleaner elements 74

10 General visual check for cracks, damage, completeness 20,47

11 Check for leaks in hoses, tubes, valves, pumps, cylinders, etc. 18,27,47

12 Drain water separator 70

13 Lubricate all grease points 65

14 Inspect / clean the radiator/cooler and engine compartment 76-77

Dail

Page

1 Inspect drive sprocket rollers (replace as needed) 73

Page

1 Replace engine oil & filter 67

2 Replace hydraulic filter(s) 69

3 Replace Planetary Oil (initial change only) 82

Page

1 Replace fuel filter element 70

2 Replace Planetary Oil (normal change interval after initial change) 82

Page

1 Replace hydraulic oil 68

2 Replace engine coolant (use SCA additive, see engine manual) 76

Every 50 operating hours

Every 250 operating hours

Every 500 operating hours

Every 1000 operating hours

RT-60/R160T/R190T ROW O&M

0404-659 2016-05

Loading...

Loading...